Why Presto tensile tester is a must-have testing machine for plastic manufacturers?

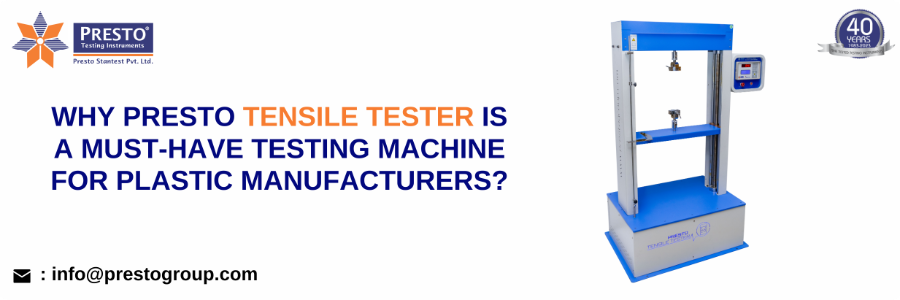

The tensile strength of plastic products plays a pivotal role in the plastic products manufacturing industry. Tensile strength is an essential parameter that determines the material's ability to withstand stretching or pulling forces without breaking or deforming. By subjecting plastic products to these quality tests, manufacturers can ensure that the products meet the required quality standards and possess the necessary durability for their intended applications. Thus, to make it easy for plastic manufacturers to conduct quality tests on the materials, we at Presto have designed a high-quality lab testing instrument known as Zeus Ultimo 3.0 tensile testing machine.

Importance of testing the tensile strength of plastics

All about Presto Tensile Strength Tester- Zeus Ultimo 3.0

Features of Presto Zeus Ultimo 3.0 Tensile Testing Machine

- Advanced load sensor sensing through advanced electronics.

- Speed Control through Variable Frequency drive automation by Graphic user interface PC.

- Highly sensitive load sensor with linearity feature and repeatability

- Cross-head travel length: 800 mm without grips

- Twin column rugged structure

- Safety limit switches for over-travel safety

- Hardened lead screws/ball screws for frictionless movement

- Load cell calibrated by NABL-approved proving ring/dynamometers

- Advanced Navigation System

- High accurate micro-controller based system controls with integrated software

- User-Friendly software with intuitive icons and robust architecture

- Inbuilt hardware/software in pen drive / Online Link.

- Easy Data Management. User programmable product identification, lot no., the shape of the specimen, company name, operator details, etc.

- USB compatible for high-speed data transfer

- Export Test report in Excel & PDF format

- Print preview of test reports with Zoom in Feature available

- Online test run status can be viewed graphically or in raw data form

- Secured working with key protection feature

- Ease of use features: Graph setup, test control wizard, result, reports, live test panel.

- Graph setup: user-defined graph scale/range with Graph Title

- Test Control Wizard to set test parameters like tension, compression, and changeable units in Kgs/N or cm/mm.

- Automatic end test/return to home position through software interface after completion of the test.

- Immediate analysis of results after the test with complete accuracy & precision.

- Option to email test reports

- Single Test start with one click entry of the mouse.

- Dual Load Cell Auto Calibration facility

- Third Load cell optional

Technical specifications of Presto Zeus Ultimo 3.0 Tensile Testing Machine

- Power: 220V, Single / Three phases, 50 Hz

- Display: Graphical with test data output through Inbuilt Software

- Accuracy: ± 2% at Full Load (with master load)

- Standard Speed: 50-500 mm/min

- Grip to Grip Separation: Min 25mm and Max. 700mm (applicable only with vice-type standard grip)

- Digital load indicator: 7-segment LED Display (optional as per request)

- Drive Mechanism: Variable Frequency AC Drive

- Safety: Yes

- Grippers(optional added based on requirement):

- Flexural

- Compression Plate

- Wedge Type

- Roller Type

- Vice Type (Standard Gripper)

- Communication Converter: USB / RS 485

- Material: Mild Steel

- Finish: Powder-coated Havel Gray & Blue combination finish and bright chrome/zinc plating for a corrosion-resistant finish

- Dimensions: 1325 x 650 x 1550 mm

Author : -Gaurav Malhotra

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free CopyNeed more information

Connect with us for your business enquiries. Generally we respond within one or two working days.

send enquiriesContact Us

How it works

Quick quote