.png)

.png)

.png)

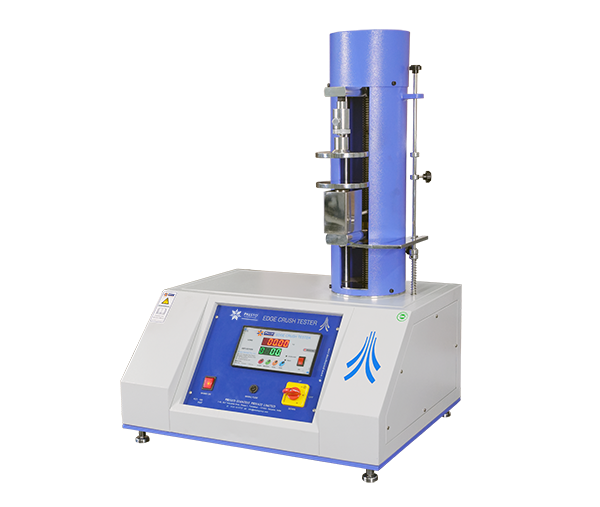

The Presto Crush Tester – Digital Model is a high-precision instrument designed to measure the crushing strength of paper, corrugated boards, and related packaging materials. This versatile model performs multiple standard tests including Ring Crush Test (RCT), Edge Crush Test (ECT), Flat Crush Test (FCT), and Corrugated Crush Test (CCT) — making it an essential quality control tool for paper and packaging industries. Checks the compression sustaining strength specifying the plies and flutes quality.

Rating

4.8/5Model PCT -100

The Edge Crush Tester – Digital (ECT) demonstrates robustness suitable for any paper and packaging production firm. It serves as the perfect testing instrument for industries such as paper making, packaging, quality inspection departments, and more. This digital ECT tester is valuable for assessing the potential compression strength of corrugated and solid fiberboard boxes by testing the paper and paperboard materials utilized in their production.

Edge Crush Tester / Ring Crush Tester / Flat Crush Tester is used for accurate testing of paper, paper-board, solid fiber-board & corrugated board for ECT test and its components. The Edge Crush tester can also be used for performing compression test on all small packages.

The higher ECT value determined by the ECT tester depicts the rigidity of the CFB box. Hence, it may be used to compare the quality of the CFB board. It is also possible to determine the compression strength of the box (CFB) by using ECT tester with McKee’s formula i.e.Compression strength = k. ECT x T x Z

Where K= Constant

ECT = edge crush test value

T=Thickness of CFB board (wall thickness)

Z= Perimeter of the box i.e. (2 L + 2 W)

Testing the edge-wise compression strength of corrugated boxes or cardboards is important in determining whether the materials will be strong enough to withstand the rigors of shipping or not. Thus, to make it easy for the paper and packaging product manufacturers to conduct the edge-wise compression strength on materials, this high-quality edge crush tester has been designed by the experts at best price in Presto.

This digital model of Crush /RCT/ECT /FCT model is for a simple and accurate read-out on a digital display. It comes with electronic force measurement for the load and the key locks embedded in this lab testing instrument will help the users to prevent accidental or unauthorized resetting.

The microprocessor-based display has also been embedded for accurate testing results. With its strong gripping clamps, bright LED display, and other advanced features, one can easily test the edge-wise compression strength of the materials. It comes with an in-built calibration facility, users can get accurate testing results every time they conduct the test.

Purchase an Edge Crush Tester directly from Presto, the trusted manufacturer at competitive prices. As a leading supplier, we provide reliable testing equipment to guarantee packaging strength.

| Load Cell Capacity | 250 Kgf |

| Display | LED (Digital) |

| Accuracy | ±2% at full load (with master load) |

| Least Count/Resolution | 0.1 Kgf |

| Power | 220V, Single phase, 50 Hz |

| Test Speed | 12.5± 2.5 mm/min |

Highlights :

| Safety Switch | Upward & Downward Limit Switches |

| Material | Mild Steel |

| Finish | Powder coated Havel Gray & Blue combination finish and bright chrome / zinc plating for corrosion resistant finish |

| Dimensions | 600x500x863 mm |

RCT/FCT/Edge Crush Tester reveals the crushing resistance in terms of Kg/Unit length.

Optional Features:

What our customers say about us is important to us.

Trusting by the best, serving the best