.png)

.png)

.png)

.png)

The Presto Dart Impact Tester is used for determining the impact of a free falling dart on a plastic film. The energy of the falling dart causes the film to fail under specified conditions. The dart has a hemispherical head and is held by a strong electromagnetic dart holder.

In stock

Rating

5/5Model PDI-Aero Series

Dart Impact Tester is a consistent tool for determining the impact of a free falling dart on a plastic film. The energy of the falling dart causes the film to fail under specified conditions. The dart has a hemispherical head and is held by a strong electromagnetic dart holder. PRESTO Drat Impact Tester is manufactured under Test Standard IS 2508: 1984( R2003), ASTM D1709-16A

PRESTO Dart Impact Tester is widely used by plastic film manufacturer for assessing the strength and durability of their plastic films, flexible films, sheets and similar other products. Works according to both Method-A and Method-B of test standard.

|

Inner Diameter of clamp |

127 mm ± 2 mm |

|

Diameter of Dart head |

• Method A– 38 mm • Method B– 50.8 mm ± 0.13 mm |

|

Drop Height |

660 mm and 1524 mm (Adjustable) |

|

Dart Weight |

5 gm to 90 gm – (Steel weight) |

|

Maximum weight holding capacity of Dart Holding Mechanism |

Upto 2 Kg (Other capacity on request) |

|

Dart Head Material |

Method A - Phenolic & Method B - Steel |

|

Least Count of Height Adjustable Clamp |

1 mm |

|

Counter |

Digital Counter |

|

Power |

220V, 50Hz, Single Phase |

|

T ype of test |

Free Falling Dart |

|

Release Mechanism |

Electromagnetic dart hold/release mechanism |

|

Clamping Unit |

Circular annular clamping unit with zero slippage |

|

Material |

Mild Steel |

|

Finish |

Powder coated Havel Gray & Blue combination finish and bright chrome / zinc plating for corrosion resistant finish |

|

Dimensions |

415x500x2153 mm |

What our customers say about us is important to us.

.png)

.png)

.png)

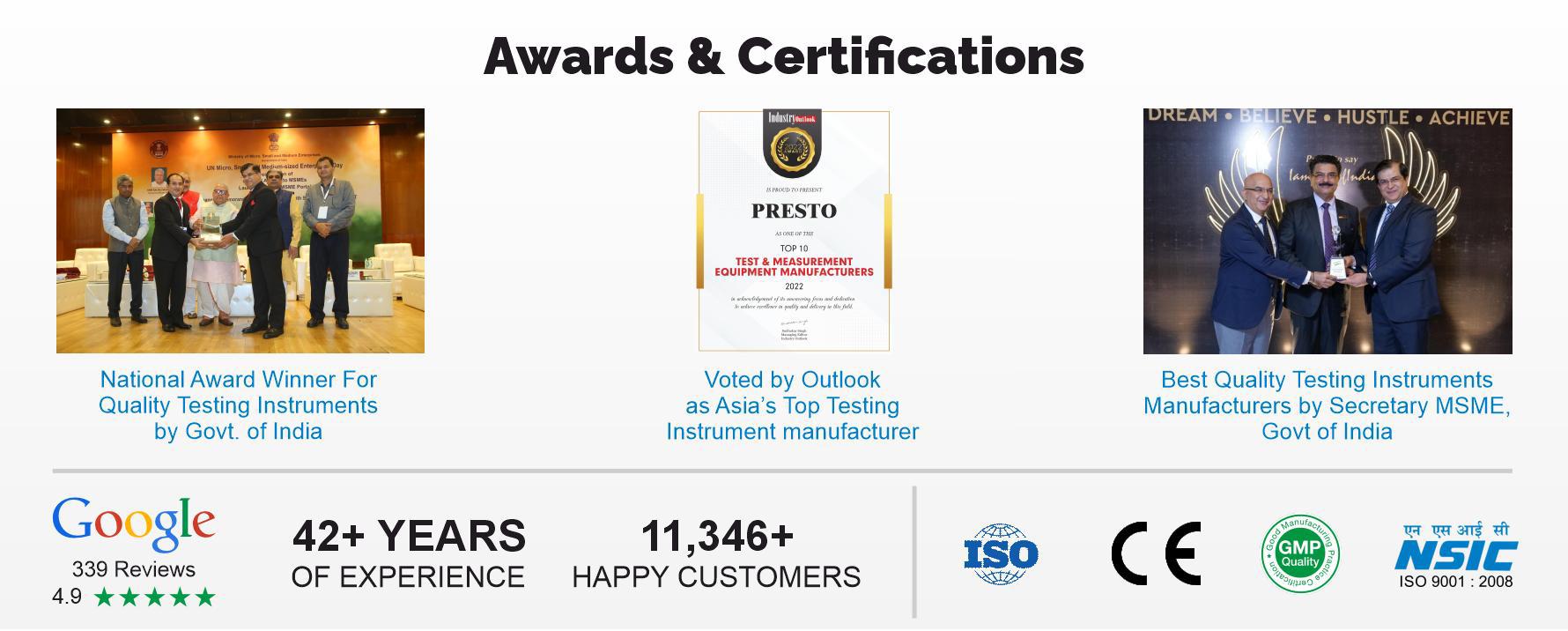

Trusting by the best, serving the best