Our Valued Clients

Top - load testing (also known as 'column-crush' and 'axial force resistance') is performed mainly on blow moulded, the

reformed or injection moulded plastic containers. It measures the compressive strength of such containers to ensure they do not

deform or break when subjected to axial forces during the processes of filling, closure, storage and transport.

Registered Design Patent No. 341519-004

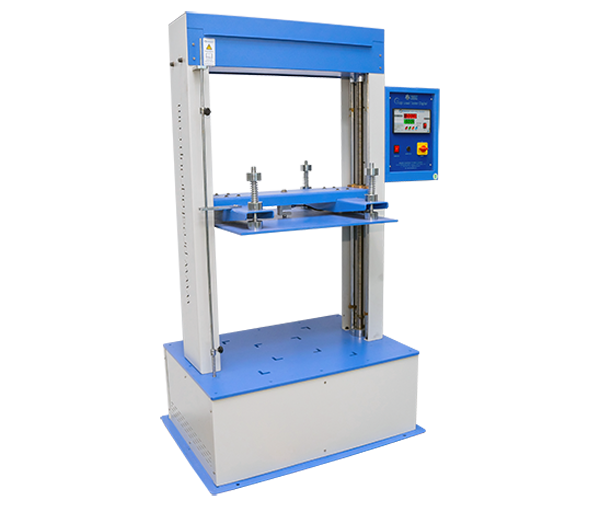

Top Load Tester - Digital Cum Computerized is a new generation fully automatic motorized top load tester. It gives Compressive Buckling Load in digital format. The digital display is a high-end sophisticated read out with Auto Tare (ZERO) set facility and Peak Hold arrangement.

The new generation Top Load Tester - Prima Series for PET bottles and jars is a fully automatic motorized device that helps to generate compressive buckling load on the products. The instrument offers compressive buckling load on Human Machine Interface based Touchscreen display.

The new generation fully automatic Computeriesed Top Load Tester for jars is a "Twin Screw model" that helps to generate compressive buckling load on the Jars. The load sensor can be calibrated in-house. The bottle needs to be placed in between the inverted compression platens.

The top load tester is designed to elevate the quality of containers & PET bottles. These containers & PET bottles are the foremost choice of manufacturers for the packaging of perishable & fluid products as they are highly durable and a good quality packaging product.

Although they are widely used by manufacturers, their buckling resistance can be an issue and might affect the product packed inside them. To curb this issue of compromised buckling resistance, the top load tester is put into the application as it exerts buckling force on these bottles & containers, enabling manufacturers to evaluate the peak buckling resistance and the deformity that takes place.

Trusting by the best, serving the best