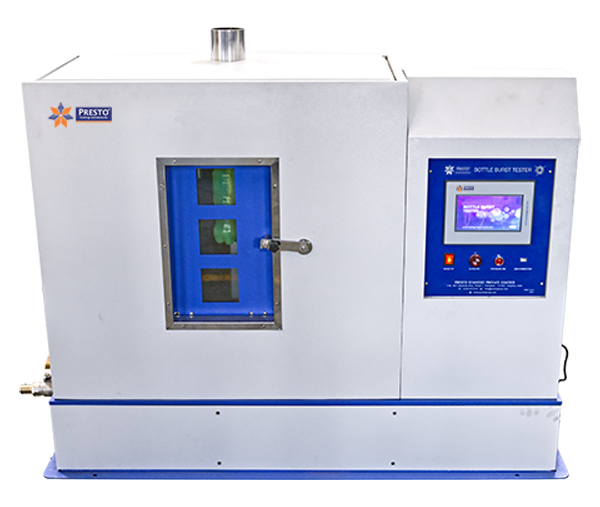

Bottle Burst Tester is a consistent tool used to perform Bottle burst test on PET bottles with minimum pressure and check the volume expansion of test samples. The testing instrument Bottle Burst Tester - Touch screen is used to measure the Burst Strength of PET bottles when subject to pressurized air.

Registered Design Patent No. 252612

In stock

Rating

5/5Model PBBT-0101

Bottle Burst Tester is a consistent tool used to perform Bottle burst test on PET bottles with minimum pressure and check the volume expansion of test samples. The testing instrument Bottle Burst Tester - Digital is used to measure the Burst Strength of PET bottles when subject to pressurized air. It measures the volumetric expansion of PET bottle under pressure conditions to rupture or burst the bottle.

PET bottles are extensively utilized in various industries for bottling a diverse range of products, including carbonated drinks. However, a common issue encountered during the bottling of carbonated drinks is the potential for PET bottles to burst under high pressure or if they possess insufficient strength.For this the manufacturers of the PET bottles need to test the burst strength of the bottles using proper testing methods and testing instruments. Touchscreen Model of Bottle burst Tester is one of the best suited testing instruments that can be used for testing the strength of the bottles.

The bottle burst test is commenced by exerting a high amount of pressure in the bottles using highly pressurized air. The pressurized air replicated the pressure exerted on the bottles when a carbonated drink is filled inside them. The testing procedure helps in testing various aspects of a bottle such as expansion volume, burst strength and thickness of the walls of the PET bottles. Presto’s Bottle burst tester Touchscreen Model model is a highly sophisticated and accurate testing instrument that is used for testing the strength of the bottles widely in PET industries and bottling units.

Standard: ASTM C147-86(2015).

What our customers say about us is important to us.

Trusting by the best, serving the best