Polariscope - Measure Strain & Transparency in Glass, Plastic Products | Presto Group

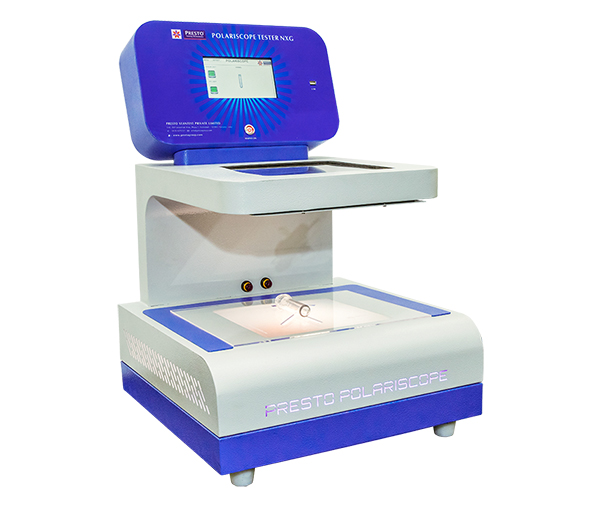

Polariscope Strain Viewer – NXG

The Polariscope Strain Viewer is a top-tier laboratory testing instrument designed to assess the quality and transparency of PET preforms. Its operation is grounded in the principle that alterations in refractive index stem from varying strain distributions, resulting in diminished material transparency.

By utilizing the Polariscope Strain Viewer, manufacturers can visualize molecular birefringent flow lines, represented in vibrant colors. Notably, the appearance of black isoclinic lines occurs when the preform axis aligns parallel to the polarizing axis of the viewer. This unique feature enables precise analysis of PET preforms, offering valuable insights into their structural integrity and transparency characteristics.

This NXG model comes with highly advanced features that make it easy for manufacturers to test the defects and strains present in the products.

Polariscope Strain Viewer Computerised

Polariscope Strain Viewer computerised is utilized for conducting Quality and Transparency test. It is used to identify and evaluate residual strain in PET preforms, bottles and similar products.

It works on the standard principle of using polarized light to identify strain in preforms. The Polariscope incorporates a polarizing filter to convert white light into a straight lined polarized beam which is directed through the sample. Actual level of stress in the specimen can easily be determined by comparing colours exhibited during the test with those produced by calibrated defect chart.

Polariscope Strain Viewer for Glass and Plastics

Benefits of Polariscope Strain Viewer

Presto's Glass & Plastic Polariscope - Strain Viewer is the best and highly effective testing device which is used to measure the residual stresses and strains that are introduced during the manufacturing process of the products that severely affects the strength of the product. These effects can be harmful as it may contribute to the product’s failure in service or it can be beneficial, as for example in the inducement of compressive stresses in the surface layers of toughened glass to increase its strength in service.

One of the most powerful methods, where the product is made of transparent glass or plastics, is based upon the photoelastic technique which involves the passing of polarized light through the product and interpreting, qualitatively or quantitatively, the resulting optical interference pattern. In the case of glass products, it is usually the residual stresses which are measured whilst in the case of plastics molding, casting or extrusions it is the strains which generally are of importance. The testing instrument is manufactured by considering relevant parameters and various standards that are introduced by standardized and reputed authorities.

The Presto Polariscope strain viewer for glass and plastics is made to easily detect the defects present in preforms and glass products. This is one of the most accurate quality lab testing instruments that make the use of a monochromatic light source for visual inspection of the testing specimen. Users can easily rely on this lab testing equipment to test the deforms present in plastic and glass products.

The sample will accurately be placed in the testing area and can be tested to evaluate different types of defects in the specimen. Users will get a sharper and clearer optical viewing experience with the use of this quality lab testing equipment. Presto offers the best Polariscope strain viewer price to our clients. With the help of this quality lab testing equipment, one can detect stress, strains, or even cracks present in plastic and glass products. The wide viewing area present in this testing equipment will give a sharper and clearer optical experience to the users. The samples can easily be tested at 45 and 90 degrees of angles. Presto is a leading Polariscope strain viewer manufacturer and offers this testing equipment embedded with high-quality and advanced testing features.

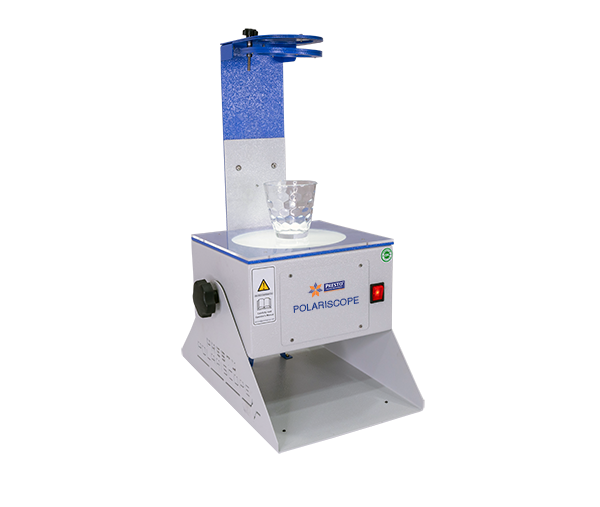

Polariscope Strain Viewer - Deluxe

Polariscope, a highly efficient strain viewer that helps the manufacturers in testing the quality and transparency of the products so that best quality assurance could be ensured to the customers. The working of the Polariscope is based on the principle that any change in refractive index is due to different strain distribution and this leads to lower transparency of the material. The testing instrument offered by Polariscope comes in variety of sizes and specifications according to the requirements of the clients

Photoelasticity is a significant phenomenon observed in PET, preforms, and glass products. It refers to the alteration in the material's refractive index due to non-uniform strain distribution. Photoelasticity poses a considerable challenge for manufacturers of PET and glass items as it represents a notable flaw in product quality.

Offers two models of Polariscope that are Polariscope Dx and Polariscope computerized. The instruments are manufactured with best quality of materials to provide an extended service life and accurate testing procedures. The testing instrument is provided protection from corrosion and rust with Zinc and chrome plating and has been given a smooth and attractive finish in grey and blue color. The instrument is also provided with an instruction manuals and a conformance certificate that can be traced to any of the NABL approved laboratories.

Purchase a Polariscope from Presto, the premier manufacturer of stress testing instruments. Get precision results at the best price from a certified supplier today.

Polariscope

The polariscope is an extremely futuristic lab testing instrument that is necessary to be installed in the manufacturing industries that deal with PET & glass products.

The instrument is designed to determine the uncertainties and irrationalities in the preform stage of a product to avoid hefty losses due to faulty mass production.

The Polariscope allows the manufacturer of the preform to visually analyze the uncertainties by comparing them through the ideal chart. The instrument simply assesses the specimen under a dual lighting mechanism that exposes its irrationalities. The two light assemblies installed in the polariscope are sodium lamp & CFL bulb for superficial testing.