Bursting Strength Tester - Measure Paper, Corrugated Board Strength | Presto Group

Bursting Strength Tester Digital Cum Computerised Model With Pneumatic Clamping

It is measured by giving a hydraulic pressure through a rubber diaphragm on a circular area of the specimen of CBF under test conditions.

The force required to burst or complete rupture of the board is measured through a Digital Indicator. The quality CFB is graded with the value of bursting strength.

Bursting Strength Tester – Digital cum computerized with pneumatic clamping is a consistent tool to indicate the Strength and performance of material like Rexene, leather, paper boards, paper, uneven boards and boxes, industrial fabric and solid fiber boards, filter cloth, plastic films, Foils, sheets, etc. Bursting strength is the force required to burst or rupture the material under testing. Bursting strength of test specimen is expressed in terms of Kg/cm². It is measured by giving hydraulic pressure through a rubber diaphragm on the test specimen.

It comes with Dual System viz.

1) Digital Display (Incase computer is not used/available)

2) Inbuilt hardware & software CD.

The equipment is built on a rigid metal base plate and finished in Autumn Gray & Blue combination painting and bright chrome / zinc plating to give it a corrosion resistant finish.

The Instrument comes complete with Instruction Manual, Two spare diaphragms, Test foil set, Electrical Wiring Diagram & Calibration Certificate traceable to NABL approved Labs.

Bursting Strength Tester - Digital Pneumatic

Bursting Strength Tester - Digital Pneumatic is provided with digital display and pneumatic clamping system for determination of bursting strength of paper, paper-board, solid fiber board and corrugated board and boxes. The equipment is widely used to get the fast and accurate test results, by use of a single instrument.

The Electronic Bursting Strength Tester provides rapid test sequence through coordinated automatic controls for clamping and testing cycles.

An electronic pressure transducer provides a high level of accuracy and excellent reproducibility of test results.

The digital display is built on a state-of-the-art robust circuitry platform to ensure repeated performance after years.

Bursting Strength Tester-Digital Pneumatic with Printer

Presto’s Bursting strength tester - Digital Pneumatic with Printer is designed to measure the bursting strength of the paper, cloth, corrugated fibre, etc. This high-end model is designed with pneumatic clamping to ensure that there is no slippage of the sample. The hydraulic pressure is applied to the sample via rubber diaphragm. The medium of pressure is glycerin. The pressure is applied on the test sample until it ruptures. The pressure required to burst the sample is considered as the bursting strength. It is represented in kg/cm². It is equipped with a small thermal printer alongside to immediately print the test results.

Bursting strength is an important factor to determine the quality of the raw material. Many industries cannot approve a bit of sample until testing it for its bursting strength.

PRESTO Bursting Strength Tester is manufactured under various Test Standards ASTM D

3786-01, ASTM D 3786 – 80A, ISO 1060 PART-1 1987.

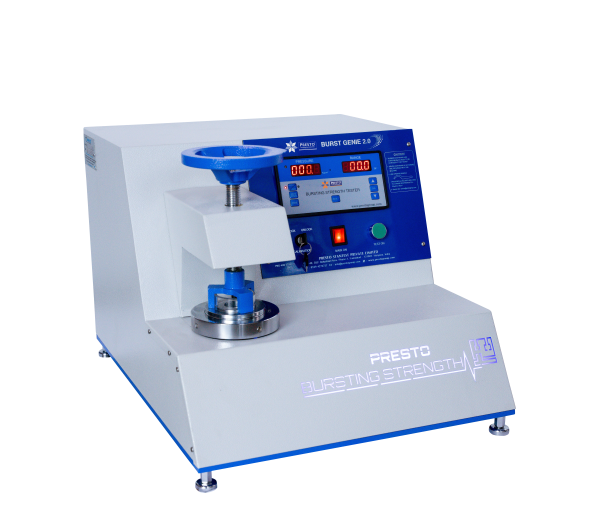

Bursting Strength Tester Genie 2.0

Working mechanism of Bursting Strength Tester Genie 2.0

The determination of the force required for the bursting or complete rupture of a material is conducted using a Digital Indicator. This bursting strength is a crucial parameter that sets the quality of the material in comparison to others. The Digital Bursting Strength Tester, offered by, operates by applying hydraulic pressure under a rubber diaphragm with a specified area onto the test sample. A bursting strength tester machine is versatile and can accurately assess the bursting strength of various materials such as paper, corrugated cardboard, carton boxes, cardboard, leather, cloth, or synthetic leather. The resulting bursting strength value is quantified in kg/cm².

Bursting Strength Tester Machine is specifically designed for measuring the bursting strength of paper and strong paperboard. The testing procedure involves preparing the specimen and securing it between two circular clamps. Using the geared handle provided, the specimen is tightened. The hydraulic pressure is incrementally applied by manipulating the handle until the specimen ruptures. The digital display then indicates the bursting strength of the test specimen in kg/cm². If you want to know more about hydraulic bursting strength tester like bursting test machine features or other related information, then you can easily contact us.

The pressure at which a film or sheet of plastic or paper will burst defines its bursting strength. A precise measure of the maximum pressure it can withstand, it is a parameter often used for evaluation of paper, plastic films & flexible packaging.

The pressure is applied on the sample at a right angle to the surface, using a bulging circular elastic neoprene diaphragm. Depending on the durability of the material and its tensile strength, Bursting Strength is expressed in pound per square inch (psi). It basically, translates into the resistance to breaking or damage, offered by the sample.

The manufacturer is able to analyse the strength of the package, as well as the quality of corrugated material. These attributes can be evaluated and graded based on its bursting strength.

Buy a Bursting Strength Tester from Presto, the industry’s top manufacturer of packaging strength equipment. Get competitive prices from a reliable supplier and ensure packaging durability.

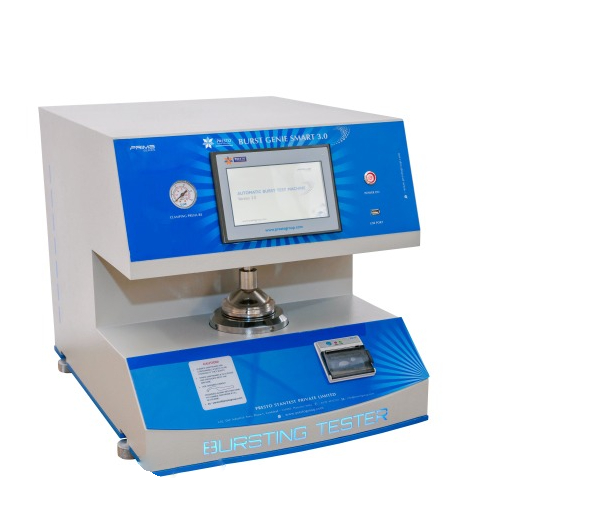

Bursting Strength Tester Genie Smart 3.0

Bursting Strength Tester is a reliable index of measurement of strength and performance of materials like paper, paper boards, corrugated boards and boxes, solid fiber boards, filter cloth, industrial fabric, leather and Rexene. With the help of a bursting strength tester, industries can ensure the best quality of products to their clients. Presto is one of the leading manufacturers of Bursting Strength tester.

Other models available of Bursting Strength Tester are: Digital Model, Pneumatic Model, Computerized Cum Digital Model with Manual Clamping and Computerized Cum Digital Model with Pneumatic Clamping.

The bursting strength of the sample is measured by applying the hydrostatic pressure required for producing rupture of the material, when pressure is applied at a controlled increasing rate through a rubber diaphragm. The value of the bursting strength will give an indication of the maximum weight that may be carried in the box. The quality of Corrugated Boxes is graded based on the value of their bursting strength. The Analogue Bursting Strength Tester is a testing instrument that offers highly reliable and accurate test results.

Bursting Strength tester

The use of corrugated sheets, aluminum foils, and other related materials is extremely prevalent in the manufacturing process as well as in the daily usage of households. These materials are also consumed in the production process of a lot of final goods because of their resilience & quality.

To enhance their standards & durability, it is vital to assess their rupturing or bursting strength which they might have to withstand once exposed to the environment.

The evaluation must be precise, and pinpoint accuracy is ensured by one & only bursting strength tester designed by the Presto Group.

The instrument delivers highly accurate test results due to its hydrostatic working mechanism, allowing the operator to enhance the rupturing strength of such materials.