The Tensile testing Machine is highly recommended for evaluating the tensile strength of products and materials. The equipment is based on the Constant Rate of Traverse (CRT) principle. It is equipped with an upper jaw and a lower jaw. Universal Tensile Testing Machine is a reliable piece of equipment which is widely used for checking tensile strength of a product/sample. One of the most common mechanical testing techniques used to determine tensile strength, this is a method wherein controlled tension is applied to a sample until it fully fails.

Thus, the material properties of the sample can be easily determined by this test. It involves measuring the force required to elongate a sample under test to breaking point. Using this test, manufacturers and quality managers are able to determine the core strength of their products.

Registered Design Patent No. 252611

Availability: In stock

The Presto grammage checking kit comprises of the GSM round cutter along with Digital weighing balance. GSM round cutter with imported industrial blades gives you a very accurate & seamless cutting of your samples.

Hot Air Oven is a unique test cabinet designed to detect the change in the physical characteristics of the material and to ascertain the actual working life of testing device at elevated temperature. Works on Forced air circulation, thermal convection principle, suitable for Tests like heat deformation, compression set, heat resistance required in rubber and plastic industries.

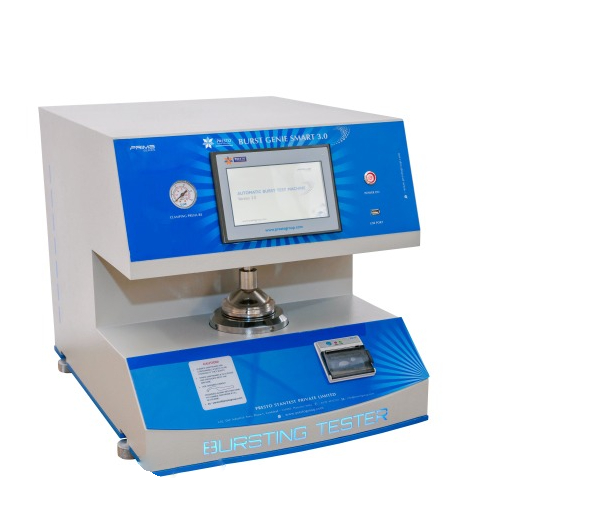

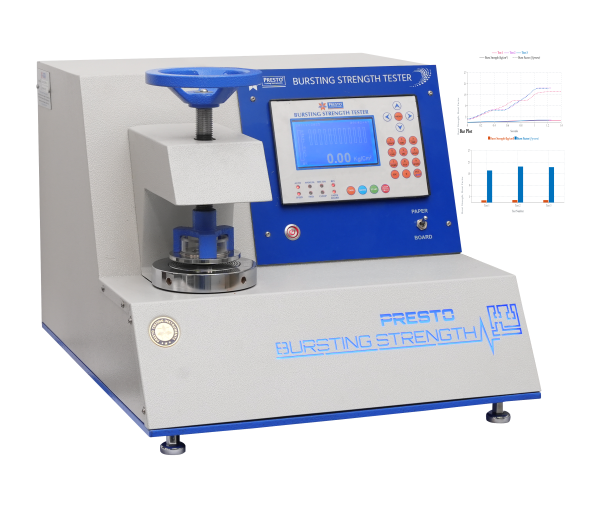

Bursting Strength Tester Genie Smart 3.0 is a reliable index of measurement of strength and performance of materials like paper, paper boards, corrugated boards and boxes, solid fiber boards, filter cloth, industrial fabric, leather and Rexene.

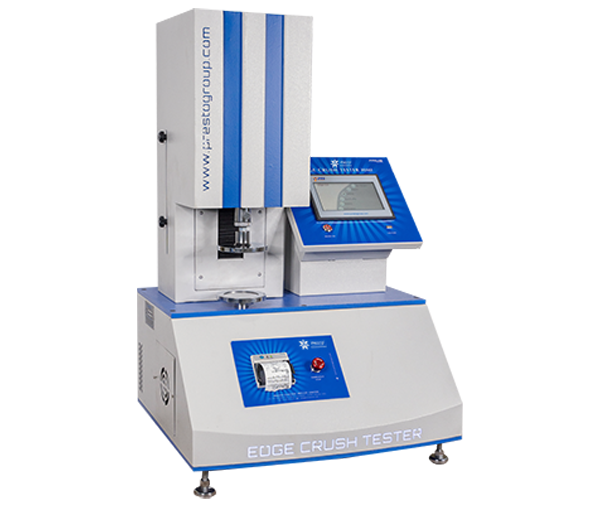

RCT/FCT/Edge Crush Tester is a consistent tool to measure the crush strength of cardboard boxes and packaging containers. RCT/FCT/Edge Crush Tester reveals the crushing resistance in unit Kg/Unit length. It is a rigid support type compression...

.png)

The Presto Crush Tester – Digital Model is a high-precision instrument designed to measure the crushing strength of paper, corrugated boards, and related packaging materials. This versatile model performs multiple standard tests including Ring Crush Test (RCT), Edge Crush Test (ECT), Flat Crush Test (FCT), and Corrugated Crush Test (CCT) — making it an essential quality control tool for paper and packaging industries. Checks the compression sustaining strength specifying the plies and flutes quality.

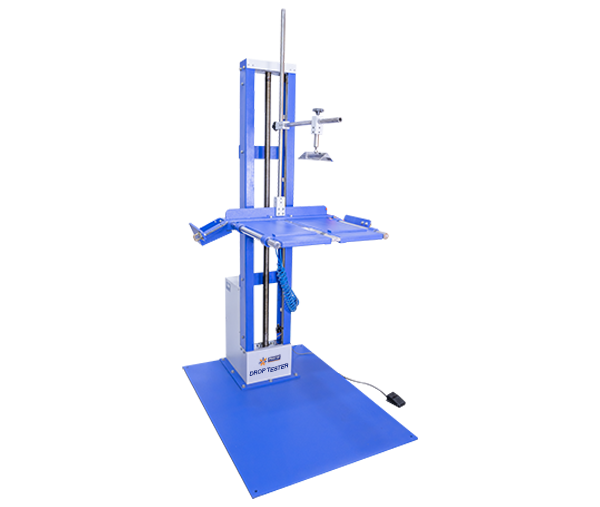

The Drop Tester (As per IS:7028 Pt IV) is a useful equipment for ascertaining the transport worthiness of corrugated & solid fiber boxes and shipping containers. It has provision with angular drop arrangement to help accurately ascertain the transport worthiness of the package from all angles.

In stock

Cobb sizing tester is used for fast determination of the quantity of water absorbed by a paper or board in a given time. The Water absorptiveness (Cobb value) of a substance is defined as the mass of water absorbed in a specific time by a 1 sq. meter...

Drop tester is the perfect machine to test the drop strength of the corrugated cartons. It is equipped with a wired remote-control mechanism to eliminate the human interference. The test specimen is observed visually after it is made to fall from a certain height. The instrument work with pneumatic application and used in almost every industry that deals with corrugated cartons.

Crease Stiffness Tester is a multi-function stiffness tester, mainly used for measuring cardboard, color box (such as cigarette case cosmetic box) of the indentation force (that is, 90° crease of the rebound force), can also measure a variety of cardboard Bending stiffness is achieved on the same instrument with two measurements: 15° flexing Degrees and 90° crease stiffness.

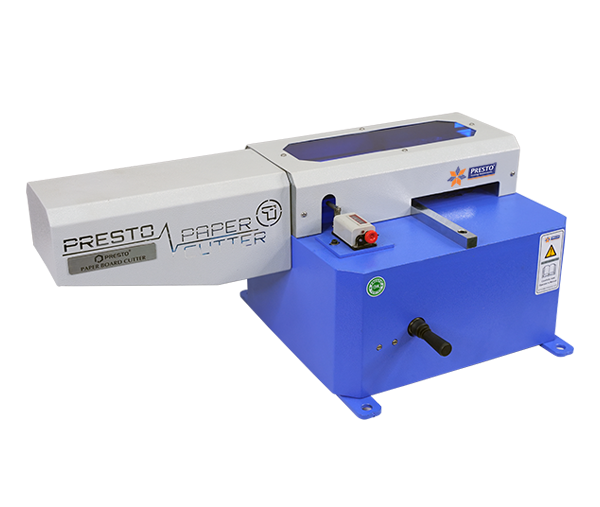

Paper and its related products are widely used in the paper and packaging industry to deliver accurate products to customers. Thus, to make it easy for the paper products manufacturers to test their material effectively, we at Presto have designed a paper board cutter. This is one of the amazing lab testing instruments that has been designed to effectively cut the samples for conducting edge crush tests on the materials.

The edge crush test is one of the common quality tests that will be conducted on the material to ensure that your product will be able to withstand edge crush force. Presto has recently introduced an edge crush-Prima model that has designed this equipment with an automated Human Machine Interface. This lab testing instrument has been designed with a stable and practical mechanical structure with uniform movement over 90 ° alignments. It has been installed with a thermal printer that can instantly print the test result without the hassle of cartridge refill.

The force required for bursting or complete rupture of the board is measured through a Digital Indicator. The bursting strength defines the material's quality as compared to the others. Bursting Strength Tester Genie 4.0 provides a hydraulic pressure on the sample. In the Presto Bursting Strength Tester, a hydraulic pressure is applied on the sample under test, using a neoprene diaphragm, on a circular area. So, a circular piece of the sample of the corrugated board is used for the test. Widely used in the paper and packaging industries, this Digital Bursting Strength Tester conforms to major global testing standards including ASTM D3786-01, ASTM D3786-80a, IS 1060 Part-1 1987, ASTM D774, ISO 2758, and ISO 2759. Compliance with these standards makes it a reliable choice for manufacturers who need precise quality control and international acceptance of their test results. Its dual test modes for paper and board, along with automatic calculation of bursting factor and pass/fail criteria, make it one of the most advanced solutions for packaging material testing.

Bursting Strength Tester Computerized –Burst genie 4.0 Computerized is a consistent tool to indicate the Strength and performance of material like paper boards, paper, uneven boards , boxes , solid fiber boards, Foils, sheets, etc. PRESTO Bursting Strength Tester is manufactured under various Test Standards ASTM D 3786-01, ASTM D 3786 – 80A, ISO 1060 PART-1 1987. Available in Various other models like digital model and Digital model with printer facility.

Tissue papers are the highly water absorbent, tear resistant and soft which is produced from paper pulp. These papers are very thin but comprises of several layers to form a combustible articles such as table napkins, facial tissues, paper towels, toilet paper, tissue paper and so forth.