Why Bursting Strength Tester is an Indispensable Part of the Automotive Industry (ASTM D3786-01, D3786)

Gaurav Malhotra

09-11-2024

In the automotive sector, durability, safety, and quality are the ultimate elements. Be it the fabric the car is upholstered with, the material that forms the airbag, or even the strength of structural parts like the bumpers or chassis of a car; each part of a car needs to be tested firmly, which would result in it withstanding the conditions it can face under extreme usage. One of the most important tests regarding this is the bursting Strength test, which measures the resistance of materials to pressure before their failure. It is very critical for the bearing of extreme conditions as in the case of internal pressure of airbags, forces acting on car seats and upholstery, and also on the structural panels in a crash.

Do you need an automatic bursting strength tester?

In the automotive industry, bursting strength becomes particularly relevant because vehicles should maintain their performance and safety under a range of stress conditions:

Airbags: Airbags inflate rapidly when the crash is hit to cushion the occupants. The textile of a bag air should have withstanding strength to the bursting pressure of rapid inflation without tearing.

Seat Belts: Materials for seat belts are required to resist elongation and rupture at high-impact forces in the event of a crash.

Upholstery Materials: Automotive seat coverings must have durability to be used as frequently as people do, and withstand passenger friction and pressure while maintaining their intended look and feel.

Structural Components: Automotive structural elements such as bumpers, door panels, and other body parts must be designed to bear both external force and impact energies to ensure the safe confinement of the occupants in a collision.

Tyres and Inflatable Products: Tyres, particularly those of high-performance and racing cars, have to bear the internal pressure as well as changing temperatures and forces while in operation.

Testing the bursting strength of such material ensures that these can operate safely and efficiently under such conditions, thus this automatic bursting strength tester has its importance for car manufacturing companies.

Now you know the Answer!

About Presto

We are one of the established companies in the world of material testing instruments. With over 40 years of experience, we provide high-precision and reliable testing products to maintain constant quality assurance for all of our clients' manufacturing industries. Our designs meet and exceed international standards to deliver sound results to clients who can rely on these results. With a firm foundation in innovation, quality, and customer satisfaction, Presto is at the helm of the testing solutions industry.

“We want to compliment you for the products and services you offer. Your responsiveness to customer queries is commendable and the way you conduct business is an example of a customer-driven approach. Thank you for your excellent and continued support. We wish you all the best. We highly recommend your products and services to others in the industry.”

~JCB

Benefits of Investing in a Bursting Strength Tester

The integration of a bursting strength tester of corrugated box into an automotive manufacturer's laboratory or production setting yields high returns on investment. The following details demonstrate this:

1. Thrice Quality Control

The bursting strength tester can be utilized by manufacturers to ensure safety and durability in critical automotive components manufactured with safety and durability standards. For example, upholstery bursting strength testing may provide prevention in fabric ruptures under stress, thus ensuring there are prolonged and safer vehicle interiors.

Companies that have an efficient testing protocol in place claim to have reduced quality control failure by up to 30%. This lowers the possibility of expensive product recalls and ensures a consistent quality of the products, which is very important for a brand's reputation.

2. Less Chances of Product Failure

The bursting strength tester of corrugated box, non-woven fabrics, and similar materials ensures that airbags, seatbelt fabrics, and car upholstery will not fail during a crash accident. Reducing the risk of material failure will therefore save on costly recalls and lawsuits with millions saved in loss.

Companies that have invested in bursting strength testing have a 40% reduction in material failures, which reduces warranty claims to 15-25%. Consequently, this saves them money for after-market service and recalls.

3. Reduced Waste Material Cost

Manufacturers can identify subpar or suboptimal materials used in mass production through their early testing, reduce waste and enhanced material selection, and ensure that only the strongest material is used in the final product for an overall reduction in production costs.

Companies that implement effective test solutions claim a 20% waste reduction in materials and 10-15% in cost savings for materials, due to better material selection, thus optimizing the cost of production.

4. Faster Time-to-Market

Such tests will enable makers to smoothen the R&D process, shortening the time it takes for vehicles or components to roll off an assembly line. Bursts in such materials can be evaluated at a critical point so that engineers use the right ones with considerable savings in time and re-testing or redesign.

Automotive companies using bursting strength tester for paper board can average 10-15% acceleration in reducing product development cycles and accelerate their products to the market with less design revision.

All in All

This will allow manufacturers who properly maintain heavy-duty test equipment, such as bursting strength testers, to reduce material waste by 15-20% and reduce product failure by 30%, and high-stress automotive applications make this even more important. In addition, quality control testing investments also cut down on warranty claims as well as customer dissatisfaction; they improve the amount of retained customers and ultimately the reputation of the brand.

Bursting Strength tester for the best fit!

We, at Presto, offer a variety of bursting strength tester for paper boards available for all different ASTM standards and industry needs. Some of the models are as follows:

1. Bursting Strength Tester Genie 2.0

Standards:

ASTM D3786-01

ASTM D3786-80a

IS 1060 PART-1 1987

Technical Specifications:

It can hold up to a Capacity of 40 kg/cm².

Comes with an LED (Digital) Display.

Its Accuracy ranges at ± 1% within 10% to 90% of the entire range as per IS: 1828.

The Least Count/Resolution is 0.1Kg/cm2.

Power 220V, Single phase, 50 Hz.

Glycerin about 98% purified (lab grade) is the test fluid used to conduct testing.

The fluid dispaces at the range of 95 cc/minute.

Motor 1/4 HP Single Phase, 1440 rpm

Test Range- Kg/cm to 38 Kg / cm2.

Highlights:

Its memory can hold Up to 9 test values.

Comes with a Peak Hold and Safety Switch Facility.

Made of Mild steel which is Powder coated with a Havel Gray & Blue combination finish and bright chrome/zinc plating for a corrosion-resistant finish.

Dimensions- 540x 600x 450 mm

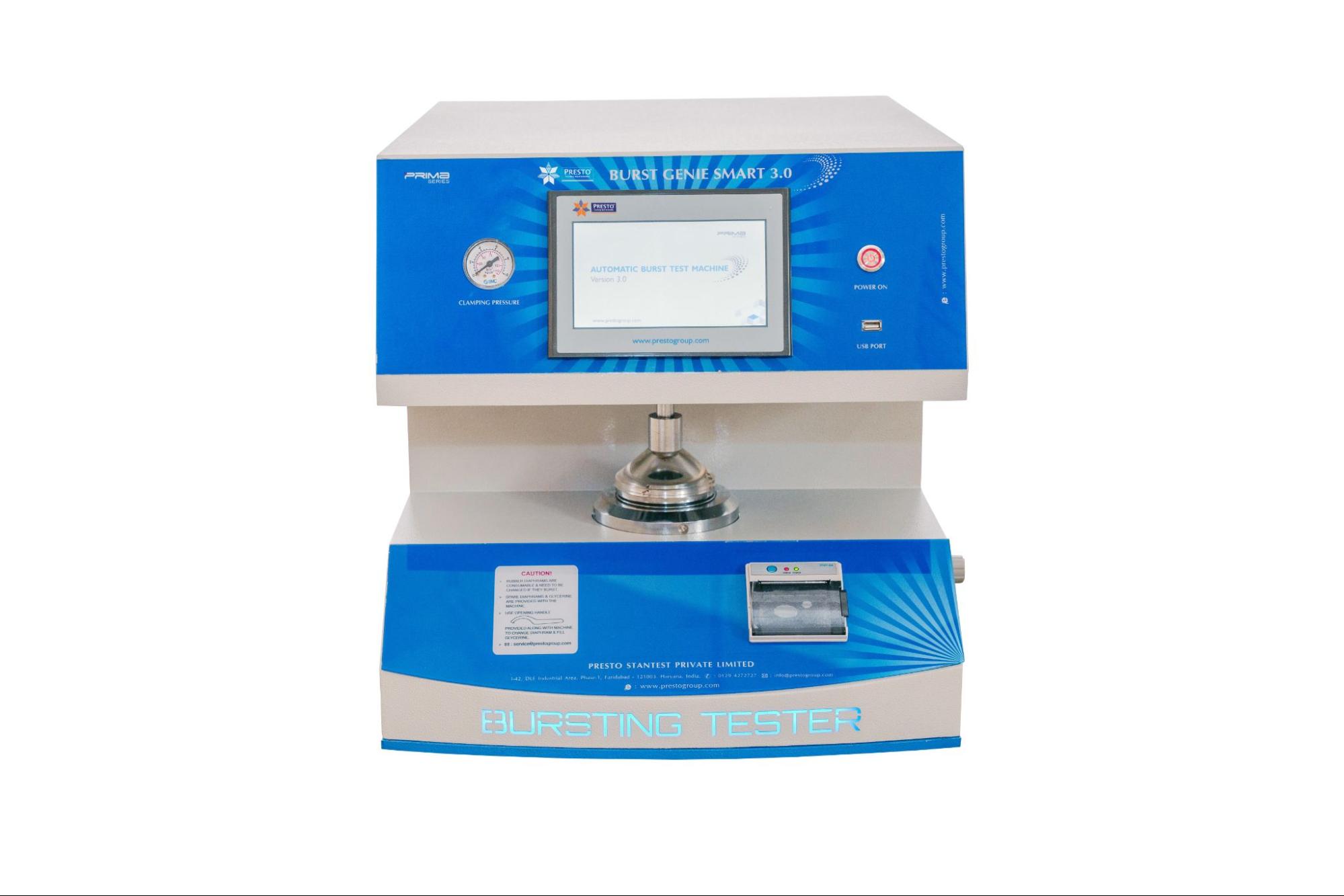

2. Bursting Strength Tester Genie Smart 3.0

Standards:

ASTM D3786-01

ASTM D3786-80a

Technical Specifications:

Comes with an Automatic pneumatic Clamping Mechanism

Display: Latest Color TFT Touch Screen

Capacity: 40 kg/cm²

Accuracy: ± 1% within 10% to 90% of the entire range as per IS: 1828 with the master gauge

Least Count/Resolution: 0.1Kg/cm2

Power: 220V, Single phase, 50 Hz

Test fluid: Glycerin about 98% purified (lab grade)

Rate of fluid displacement: 95 cc/minute

Motor: 1/4 HP Single Phase, 1440 rpm

Test Range: 0.5Kg / cm2 to 38 Kg / cm2

Memory(to hold test value): Up to 9 test values

Peak Hold Facility: Yes

Safety Switch: Yes

Material: Mild Steel

Finish: Powder-coated Havel Gray & Blue combination finish and bright chrome/zinc plating for a corrosion-resistant finish

The report can generate: Yes (Sample Results and Bar Graph)

Thermal Printer: Yes

Computer Connectivity: Yes (VNC software with advanced security features)

Dimensions: 475 x 648 x 480mm

3. Bursting Strength Tester - Digital Pneumatic

Standard:

ASTM D3786

BS 3137

ISO 2758

ISO 3303-1:2012

ISO 3689-1983

IS – 1060 – 1987

Technical Specifications:

Range: 40kg/cm2

Least Count: 0.1kg/cm2

Display: LED (Digital)

Specimen Clamping: Pneumatic

Pressure Sensor: Pressure Transducer

Test fluid: Glycerin about 98% purified(lab grade)

Rate of fluid displacement: 95 cc/minute

Dimensions: L 60cm x W 55cm x H 45cm

Approximate Weight: net 77 Kg, Gross (Packed): 93 Kg

Power Requirement: 220 Volt; 50 Hz AC, Single phase

4. Bursting Strength Tester-Digital Pneumatic with Printer

Standards:

ASTM D3786-01

ASTM D3786-80a

ISO 1060 PART-1 1987

Technical Specifications:

Capacity- 40 kg/cm²

Display- LED (Digital)

Specimen Clamping- Pneumatic 2 - 5 Bar pressure

Accuracy- ± 1% within 10% to 90% of the entire range as per IS: 1828 with the master gauge

Least Count/Resolution- 0.1Kg/cm2

Pressure Sensor- Pressure Transducer

Power 220V, Single phase, 50 Hz

Test fluid- Glycerinabout 98% purified (lab grade)

Test fluid- Glycerinabout 98% purified (lab grade)

Rate of fluid displacement- 95 cc/minute

Motor- 1/4 HP Single Phase, 1440 rpm

Test Range- 1Kg / cm to 38 Kg / cm2

Highlights:

Memory(to hold test value) Up to 9 test values

Peak Hold Facility- Yes

Safety Switch- Yes

Printer Yes (Inbuilt)

Material- Mild Steel

Finish Powder coated with grey & Blue combination finish and bright chrome/zinc plating for corrosion corrosion-resistant finish

Dimensions- 540x600x450 mm

Printer Type- Thermal Printer

5. Bursting Strength Tester Digital Cum Computerised Model With Pneumatic Clamping

Standards:

ASTM D3786-01

ASTM D3786-80a

ISO 1060 PART-1 1987

Technical Specifications:

Capacity- 40 kg/cm²

Display- LED (Digital)

Accuracy- ± 1% within 10% to 90% of the entire range as per IS: 1828 with the master gauge

Least Count/Resolution- 0.1Kg/cm2

Power 220V, Single phase, 50 Hz

Test fluid - Glycerinabout 98% purified (lab grade)

Rate of fluid displacement- 95 cc/minute

Motor 1/4 HP, Single Phase, 1440 rpm

Test Range- 1Kg / cm to 38 Kg / cm2

Highlights:

Memory (to hold test value) - Up to 9 test values

Peak Hold Facility

10 sample test reports in one report

Safety Switch

Mild Steel with Powder coated Havel Gray & Blue combination finish and bright chrome/zinc plating for corrosion-resistant finish

Dimensions- 540x 600x 450 mm

Communication port RS 232

5. Bursting Dual Head for Paper and Board

Standards:

ASTM D 774

ASTM D 774 4M-96A-Paper

TAPPI T 403 om-91 (Paper), T 810 om-92 (Corrugated & Solid Fibreboard), T 807 (Paperboard and Liner board)

ISO 1060 PART-1 1996.

Technical Specifications:

Display: LCD (Digital)

Capacity: 40 kg/cm²

Accuracy: ± 1% within 10% to 90% of the entire range as per IS: 1828 with the master gauge

Least Count/Resolution: 0.1Kg/cm2

Power 220V, Single phase, 50 Hz

Test fluid: Glycerin about 98% purified (lab grade)

Rate of fluid displacement: 95 cc/minute

Motor: 1/4 HP Single Phase, 1440 rpm

Test Range 2 2 0.6 Kg / cm2 to 38 Kg /cm2

FAQs

What is a Bursting Strength Tester?

A bursting strength tester is a lab equipment applied to measure the resistance exhibited by material to internal pressure till rupture or failure. At the time of testing, the hydraulic pressure is gradually applied to the material sample, while the moment of rupture is recorded to calculate the material's bursting strength.

The calculation procedure of Bursting Strength, What is the formulae?

This is the pressure applied onto a sample of the material till it bursts, and this is recorded as the bursting strength of the material. The bursting strength test of corrugated box is normally conducted according to standards, for example, ASTM D 3786 for paperboard or ISO 13938 for textile. Formulae for Calculating Bursting Strength Test = B.F =B.S x 1000/GSM.

How Do I Test Fabric Bursting Strength?

To test for the bursting strength, a sample is loaded into the tester that subjects the hydraulic pressure to the same fabric in which it has been placed. The tester measures the pressure that takes for the rupture of the fabric. This test is of very much importance on materials used in airbags, seatbelts, and upholstery so as to have the ability to work under the forces that come with a crash.

In the present very competitive automotive market, today no compromise can be made in respect of safety, durability, and quality of material. Bursting strength testers ensure that materials such as airbags, upholstery, and structural components are subjected to realistic forces they would experience in real life. Improve quality control, reduce material costs, decrease product failures, and generate impressive returns on investment with the addition of Presto's bursting strength tester to your lab or production process.

Ready to invest in the future of automotive testing? Contact Presto to discuss our range of bursting strength testers to help you meet the industry's highest standards.

Phone: +91 9210 903 903

Mail: info@prestogroup.com

you may also like

- The Ultimate Guide to Universal Testing Machines (UTM)

- Guide to Bursting Strength Tester: Working, Benefits & Price

- Ultimate Guide to Melt Flow Index Tester: Operations, Advantages, and Uses

- A Complete Guide to Box Compression Tester: Methods & Applications

- Hot air oven not working? Common problems & fixing issues

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Get a Quote