Vishal Malhotra-Testing Instrument Expert

23-4-2025

Product safety, along with shelf-life, depends on proper aseptic sealing used in manufacturing packaging. Every packaged food item, together with pharmaceutical products, requires leak-proof packaging to maintain product integrity throughout distribution. The testing procedure of a packaging Vacuum Leak Tester scans for imperfections that people cannot notice visually.

This blog explains vacuum leak tester functionality alongside testing procedures with the required equipment and advantages for measuring flexible packaging materials, along with bottles. Quality control labs trust the Presto Vacuum Leak Tester as their preferred solution due to its credibility.

The Vacuum Leak Tester serves as a quality control instrument which uses vacuum pressure to detect package leaks on test specimens. Through its operational mechanism, this device can detect pinholes as well as micro leaks and inferior packaging seals. This equipment is ideal for:

Packaging defect detection through the vacuum leak test follows a basic procedure which produces effective results.

Step-by-Step Testing Process:

Air bubbles indicate a leak.

The installed vent system returns the chamber pressure to match the atmosphere outside.

| Low vacuum | 12.5 ± 0.5 in. Hg |

| Medium vacuum | 18.5 ± 0.5 in. Hg |

| High vacuum | 24.5 ± 0.5 in. Hg |

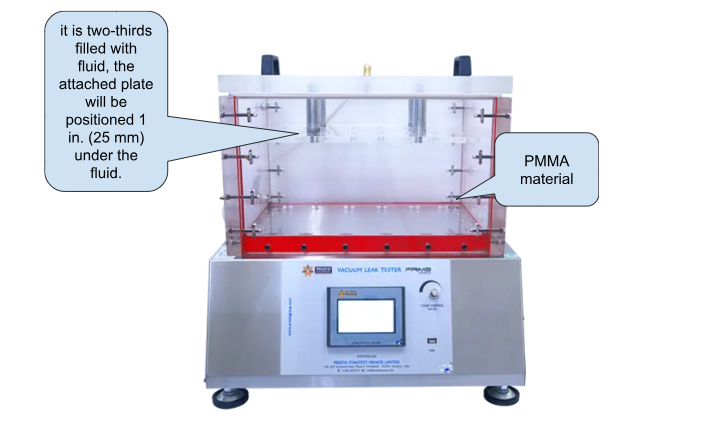

Any transparent container with a vacuum-tight cover that can endure a pressure differential of around one atmosphere is called a vacuum chamber. A gauge for vacuum,

The chamber lid must be fitted with an inlet tube from a vacuum source and an output tube to the atmosphere. Hand valves must be installed in the input and exit tubes. A transparent plate that closely resembles the container's interior dimensions and is spaced far enough from the top of the container so that, when it is two-thirds full of fluid, the attached plate will be positioned 1 inch (25 mm) below the fluid is attached to the underside of the cover.

Industrial consistency of packaging quality becomes possible via the Vacuum Leak Tester when testing both flexible packaging and rigid containers.

1. Flexible Packaging

2. Rigid Packaging

You can find our Bottle Leak Tester for rigid containers, which is available on the market.

Top brands select the Presto Vacuum Leak Tester because of its innovative structure and complete precision controls, together with its ability to meet worldwide quality standards. Key benefits include:

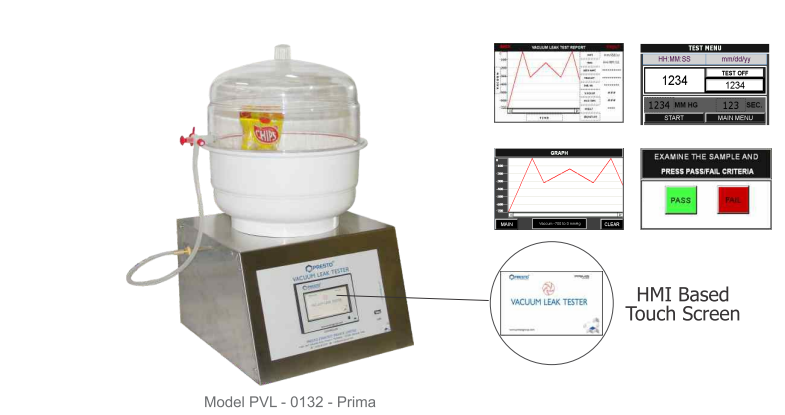

The schematic diagram of the Vacuum Leak Tester incorporates the chamber structure as well as operational controls.

Different manufacturing industries depend on vacuum leak testing equipment for their operations. Various industries apply this equipment across their operations.

Transparent packaging must be leak-proof because it helps satisfy customers together with maintaining FSSAI, FDA and ISO compliance standards.

Read more about Packaging Quality Testing Equipment

The absence of proper testing allows packaging failures to result in several detrimental consequences.

The testing method serves to protect consumers from these mentioned risks by verifying product safety during shipping.

Here is a quiz about Leak Testing Inferential procedures to test if you can answer the questions correctly.

A. Proper sealing

B. A leak in the package

C. Strong vacuum

D. None of the above

Correct Answer: B. A leak in the package

Generators that perform vacuum leak testing provide extended packaging endurance and lower customer sending rates as well as maintain product brand quality. You can achieve reliable testing results by using the Presto Vacuum Leak Tester because it serves both flexible and rigid packaging needs.

Presto Vacuum Leak Tester provides an easy way to achieve leak-proof packaging always. Acquire a free demonstration of the Presto Vacuum Leak Tester through this link.

Our packaging experts are available by phone and email.

The Presto Vacuum Leak Tester provides leak-proof packaging results through accurate measurements which can be consistently replicated.

Get top-quality testing equipment at the most competitive Vacuum Leak Tester price in the market.

Call us now at +91 9210 903 903 or Email us at info@prestogroup.com for a free quote and expert consultation!

Related Blogs

Explore how a humidity chamber operates with insights into its working principle, detailed diagram, and practical applications across industries like packaging, electronics, and pharmaceuticals.

Optimize packaging durability with Top Load Testers. Evaluate the vertical load a container can withstand before buckling or deformation occurs.

A polariscope is a machine that uses a unique light to see how other things modify light. It usually consists of two polarizing filters, or polarizers, positioned in a particular way.