Gaurav Malhotra

17-9-2024

Are you ready to dive into GSM machines? These are important machines when it comes to testing textiles. If at all you're wondering about the GSM checking machine, paper GSM checking machine, or the GSM calculator machine, look no further because it's here. In this blog, we will break down what these machines do, why they are important, and what you can make of them. We shall be discussing frequently asked questions related to GSM testing, which include buy and price RECAP. Get ready!

What Is a GSM Machine?

A GSM machine is equipment that calculates the density of fabrics in weight using units known as "grams per square meter." The term GSM stands for grams per square meter, a method of calculating fabric weight and density to meet those textiles with specified quality and standards.

Why is this? Do you feel that different fabrics feel differently? It is at least partly due to GSM. A high GSM refers to a more voluminous and dense textile, while a lower GSM connotes a lighter-weight textile. In textile production, the right measurement of GSM will be able to ensure consistency and quality.

Why Is GSM Testing Important?

Why would manufacturers be concerned with the testing of GSM? Here are some key reasons why:

Quality Control: There is consistent product quality by virtue of making sure fabric weights meet proper specs.

Product Development: Accurate GSM measurements go a long way in the development of new textile products so they are made to perform as expected.

Compliance: Many industries need to follow certain GSM standards to meet different types of safety, durability, and performance criteria.

Amazing, isn't it, how something as simple as fabric weight can make such a huge difference in product quality?

Types of GSM Machines

Wonder how many types of GSM machines are available? Let's explore some common ones here:

General-purpose Machine for GSM Checking: This machine is used in measuring the GSM of all kinds of fabrics. It is mainly used for routine checks and assurance of quality.

Paper GSM Checking Machine: This machine is designed for measurement, especially of the weight of paper products in grams per square meter. It finds application in the paper industry where it ensures that the sheets of paper are of the correct weight and consistency.

GSM Tester: This is an elaborate, versatile device for any detailed GSM testing; the machines usually include some extra feature or two, like digital readouts and data logging.

GSM Calculator: An advanced device that does the calculation of GSM through various means. They often come in software packages that help carry out comprehensive analyses.

Which of them would you think would best serve your requirements? Remember, here, what exactly does one need a machine for fabric or for paper, or both?

How Does a GSM Machine Work?

Curious about how a GSM testing machine works? Here is a general definition of how it all works:

Sample preparation: The sample, whether it's a piece of fabric or paper, should always be cut according to standard size, usually as indicated by the GSM machine guidelines.

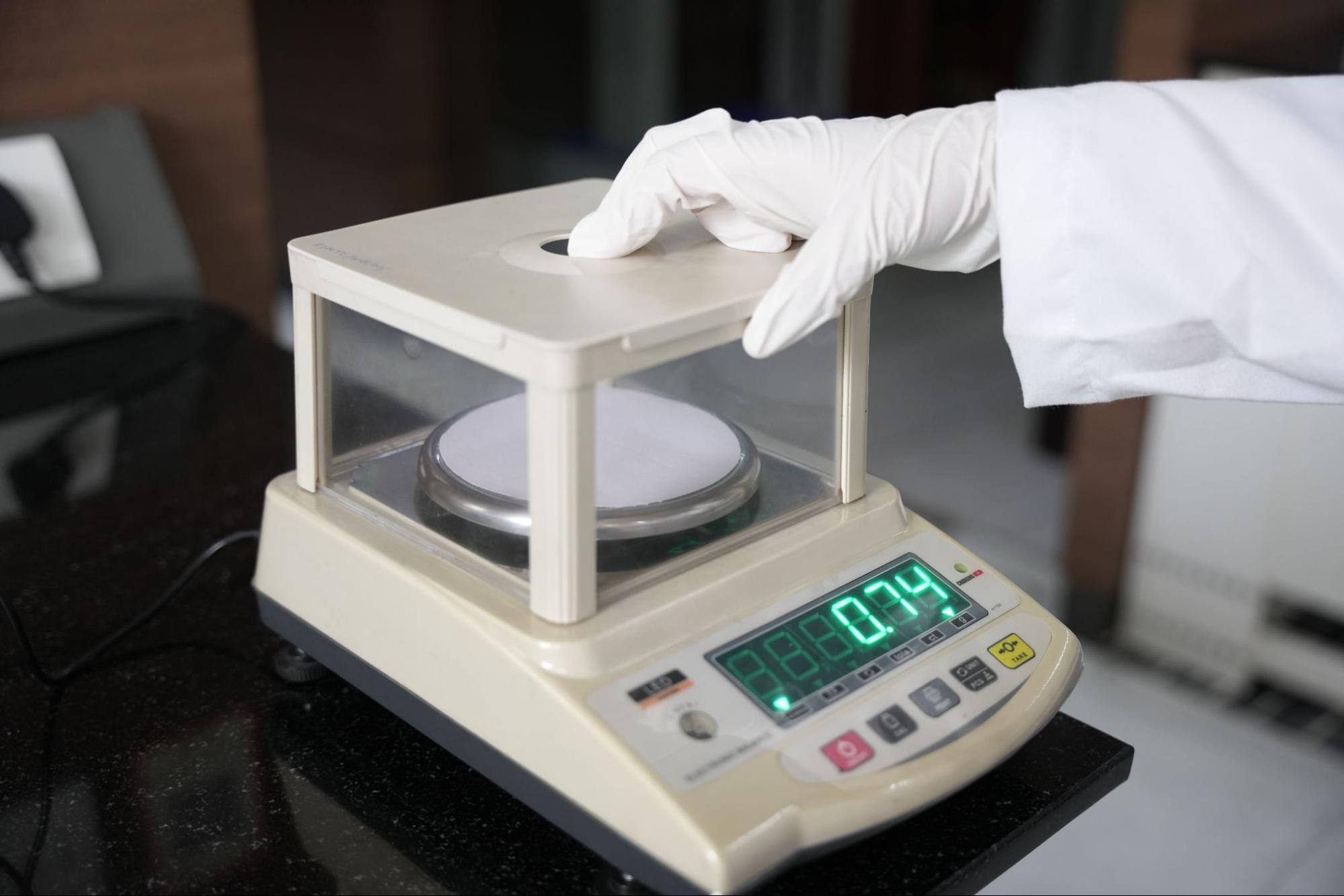

Weighting: A fine balance is utilized in weighing the sample so as to establish the weight in grams.

Computation: The machine computes the GSM through a simple division of the sample weight with the sample area usually measured in square meters.

Presentation of Results: The GSM value that would now be presented by the machine would be applicable to quality control or conformity.

Have you ever used GSM machines in your operation? What do you find most useful about it?

GSM Calculator Machine: A closer look.

What's so special about a GSM calculator machine? Depending on the manufacturer, advanced features may include:

Digital Display: This can be more accurate and sometimes easier to read than an analogue model.

Data Logging: The ability to record and track GSM measurements over time.

Software Integration: Some machines can integrate with even more advanced software for greater depth in analysis and reporting. Would any of these advanced features help your testing process?

Buying and Pricing Considerations

Do you plan on purchasing a GSM machine? Following are the things to consider while evaluating the options and buying, and the price of these machines.

Type of Machine: Fabric, paper, or all-purpose; depending on the particular needs of the customer.

Features: Consider whether the machine has a digital display, data logging, and software integration when considering the issue based on functionality and what the operations require.

Budget: GSM machines can be very expensive; some models and brands will fit within your budget while offering the features you need. Buy from reputable vendors known to offer quality and reliability so that you get a machine that does well and lasts. How much would you budget for a GSM machine? How would you balance the cost with features?

Frequently Asked Questions About GSM Testing

1. What is a GSM machine?

A GSM machine is an apparatus that is applied to measure the weight, expressed in grams, of a piece of fabric or paper per square meter. The tool determines how thick or dense the material is in quality.

2. Why do you think the importance of using a GSM cutter?

A GSM cutter cuts the size of the sample of fabric or paper to be tested at the right dimension. The same sizes are required to obtain accurate measurements of the GSM.

3. What are the 3 varying kinds of GSM?

GSM can vary from one extreme to another depending on the material and intended use. Generally speaking, fabrics can be described in terms of three classes:

Low GSM: It is light in weight with materials like a t-shirt, and lightweight linings.

Medium GSM: This is a mid-weight material like in dressing shirts, and casual wear.

High GSM: These are heavyweight materials -like jackets or upholstery.

4. What is the GSM formula?

GSM formula uses calculating the grams per square meter of fabric. This is commonly calculated as follows:

GSM = Weight of Sample (in grams)/Area of Sample (in square meters)

This formula allows for minimum error and consistency in the measurements.

So, with this, how much do you think GSM machines are important in the testing of textiles? From knowing how they work to buying and price, these machines keep your material good quality and consistent.

Have you ever worked with a GSM machine in your quality control processes? What problems did you face or what successes have you encountered? Are you considering buying one? Which features are you interested in? Call us Today!

Phone: +91 9210 903 903

Mail: info@prestogroup.com

Cheers to mastering the art of GSM measurement and ensuring the highest standards in your textile products!

No recent blogs found.