Gaurav Malhotra-Testing Instrument Expert

04-3-2025

A Melt Flow Index Tester is a device used to calculate the value of ease of flow of polymer melts at certain temperature and pressure conditions. This is very important to industries such as plastics, automotive, packaging, and medical devices to make sure the raw materials are within the required quality parameters.

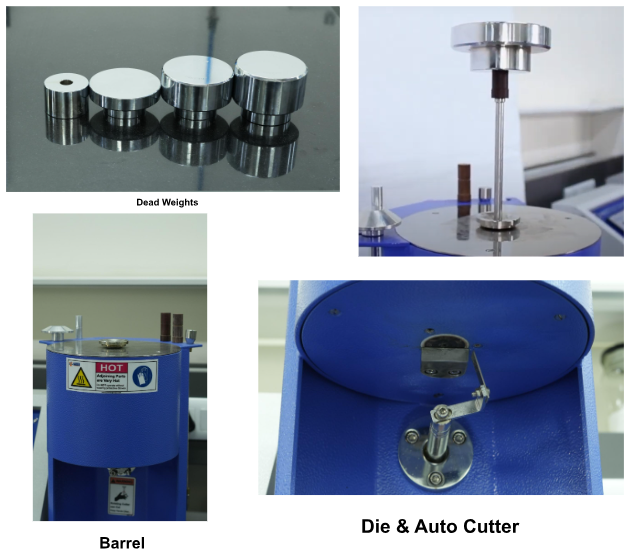

A Melt Flow Index Tester determines the quantity of plastic that flows within a particular time frame to ascertain the temperature viscosity and quality of the plastic. A plastic sample is heated in a barrel and a standard weight is placed over the sample through a piston. The molten plastic is then forced through a die and the material that comes out is caught on an electronic scale. Every 10 minutes, the scale is set to Zero and the amount of material constantly increases and is recorded with a digital readout in g/10 min, higher values indicating a lower MFI. The extruded material is weighed during a period of 10 minutes and based on the results g/10 min will be assigned to a combination of MFI and melt strength. Depending on MFI, processing can be easily carried out.

1. Plastic Manufacturing:

2. Packaging Industry:

3. Automotive & Aerospace Industry:

4. Medical Equipment:

A MFI Tester is used to determine the flow rate of molten plastic under specific conditions. It helps manufacturers assess material quality, consistency, and suitability for different applications. The MFI test is crucial in industries like packaging, automotive, and medical devices, ensuring proper processing and product performance. By measuring melt flow properties, aids in polymer selection, quality control, and compliance with industry standards like ASTM D1238 and ISO 1133.

The test is based on the concept of polymer melt flow under a controlled temperature and applied weight. Inside a heated barrel the polymer is melted and extruded through a capillary die using a specific force. Weight of the extruded material in grams per 10 minutes is recorded as the Melt Flow Rate (MFR).

1. Rheology:

The study of flow behavior in the thermoplastic polymer is the principle used behind the action performed by the MFI tester.

2. The procedure of Testing _ASTM D1238

Procedure A: Usually MFI is 0.15 gm/10 min to 50 gm/10 min for polymer granules. It is the common method of performing the Melt flow index test.

Procedure B: This not only considers the Melt flow rate but also the Melt Volumetric rate to analyze the rheological properties of the sample.

Procedure C: This method is also known as the Half Die method which is usually for very high MFI value samples.

Procedure D: It refers to a multi-weight test to analyze the flow rate ratio to more comprehensively determine rheological properties.

Different plastics have unique melt flow index values depending on their molecular weight and processing requirements. Below are some typical MFI values:

| Plastic Type | Melt Flow Index (g/10 min) | Test Conditions |

| Polypropylene (PP) | 1 - 30 | 230°C / 2.16kg |

| Polyethylene (PE) | 0.1 - 20 | 190°C / 2.16kg |

| Polystyrene (PS) | 2 - 25 | 200°C / 5kg |

| Polycarbonate (PC) | 3 - 15 | 300°C / 1.2kg |

| Acrylonitrile Butadiene Styrene (ABS) | 1 - 10 | 220°C / 10kg |

Manufacturers use these values to determine the best application for each plastic type in various industries. By following ASTM D1238 specifications, the Temperature and weight for MFI of the specific material grade of polymer can be determined.

The Melt Flow Index (MFI) is calculated using the formula:

MFI (g/10 min) = (Mass of extruded polymer in grams) / (Time in minutes)

Where:

By using this formula, manufacturers can standardize plastic material properties and ensure consistency in production.

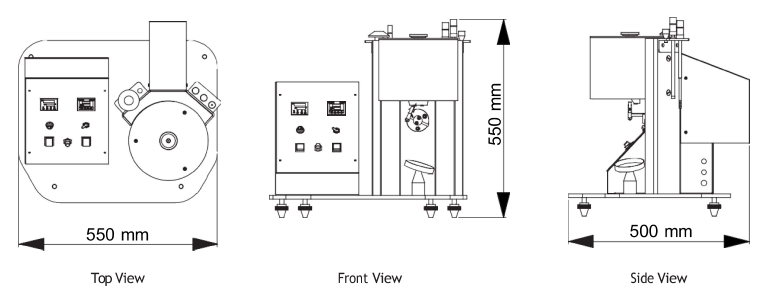

A diagram of a Melt Flow Index Tester helps to understand its working mechanism. Below are the main components:

(Here, a labeled diagram should be inserted to visually explain the MFI testing process.)

Q1: How to measure melt flow rate?

A: Melt flow rate is measured by heating a polymer sample, applying a specified load, and recording the weight of the extruded material over a set time. The result is expressed in grams per 10 minutes.

Q2: What is the instrument used for the melt index?

A: The instrument used for measuring melt index is called a Melt Flow Index Tester or Melt Flow Indexer, following ASTM D1238 and ISO 1133 standards.

Q3: What is the melt flow indexer used for?

A: A melt flow indexer is used to determine the viscosity, molecular weight, and processability of plastic materials, helping manufacturers select the right polymer grade for different applications.

Q4: What is the standard test method for MFI testing?

A: The most common methods are ASTM D1238 and ISO 1133.

Looking for a high-quality MFI testing machine at a competitive price? We offer reliable and precise MFI testing machines to meet your polymer testing needs. Contact us today at +91 9210 903 903 or email us at info@prestogroup.com to get the best MFI testing machine price and expert guidance. Ensure accurate melt flow index testing with our advanced equipment!

Related Blogs

A polariscope is a machine that uses a unique light to see how other things modify light. It usually consists of two polarizing filters, or polarizers, positioned in a particular way.

A Hot Air Oven uses dry heat to sterilize, dry, or heat materials. Widely used in labs, hospitals, and factories, it ensures safe, efficient, and even heat distribution.

GSM (Grams per Square Meter) in fabric is calculated using GSM = (Weight of Sample in grams × 10,000) / Area in cm² to determine fabric weight, thickness, and quality.