Gaurav Malhotra

09-10-2024

The fast world of manufacturing is the result of which packaging becomes crucial in aspects of functions and aesthetics. Manufacturers are tasked with the challenge of producing packaging that should not only appeal in terms of appearance but also withstand the dextrose it will undergo throughout transportation, handling, and storage. This is exactly where the dart impact tester comes into play. It is crucial to understand the impact resistance in packaging materials. This type of tester helps manufacturers well by giving them the information needed to get their products from manufacturer to consumer in pristine condition.

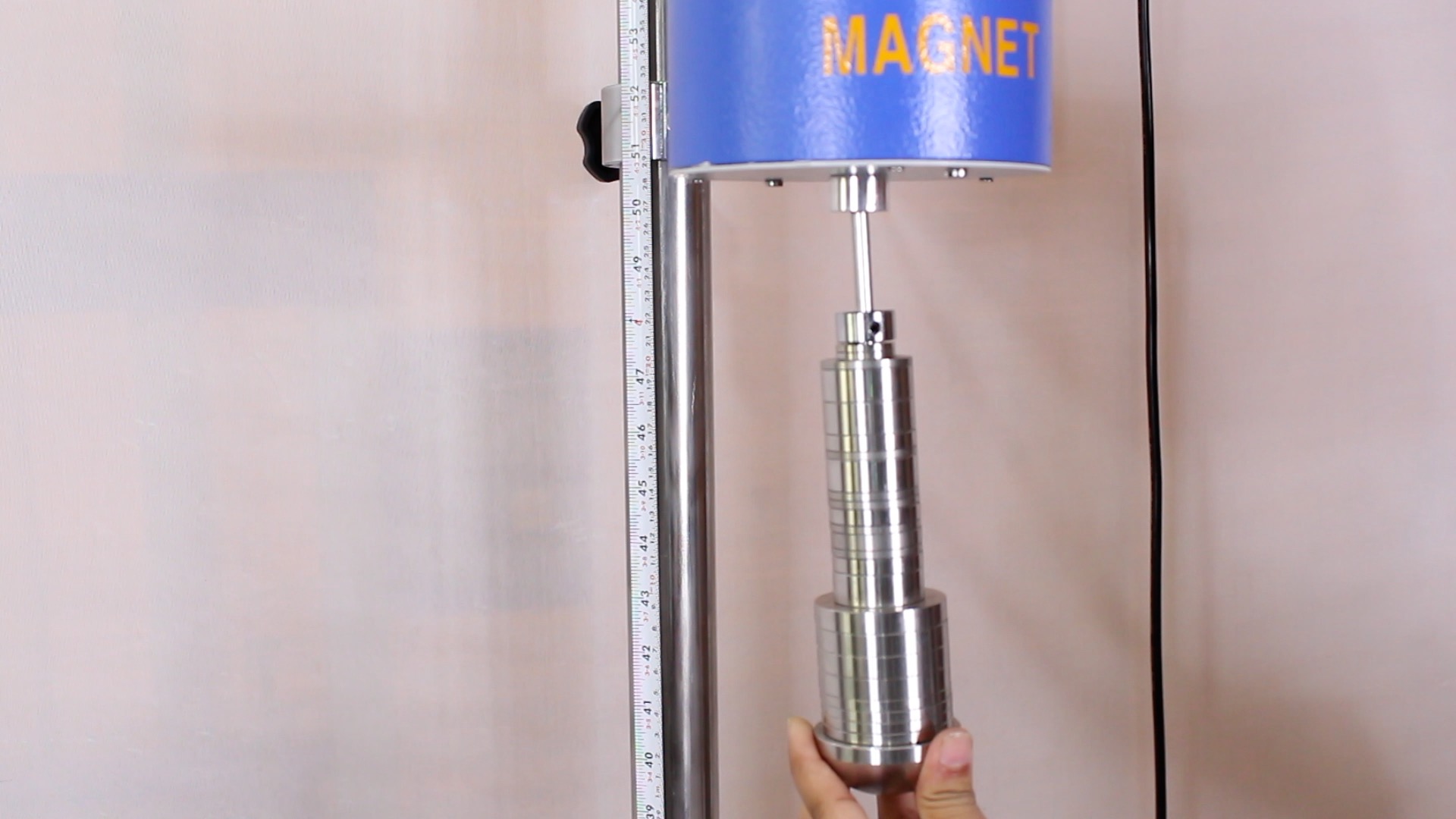

It is an apparatus that measures the impact resistance of plastic films and other materials by making it replicate how impacts caused by falling objects appear. It measures the ability of a package to resist shock impact. This testing equipment uses a dart, dropping from an ascertained height to quantify the energy absorbed by the impacted material.

Meanwhile, a dart impact tester is rather interestingly simple in its mechanism. Here is a broad outline:

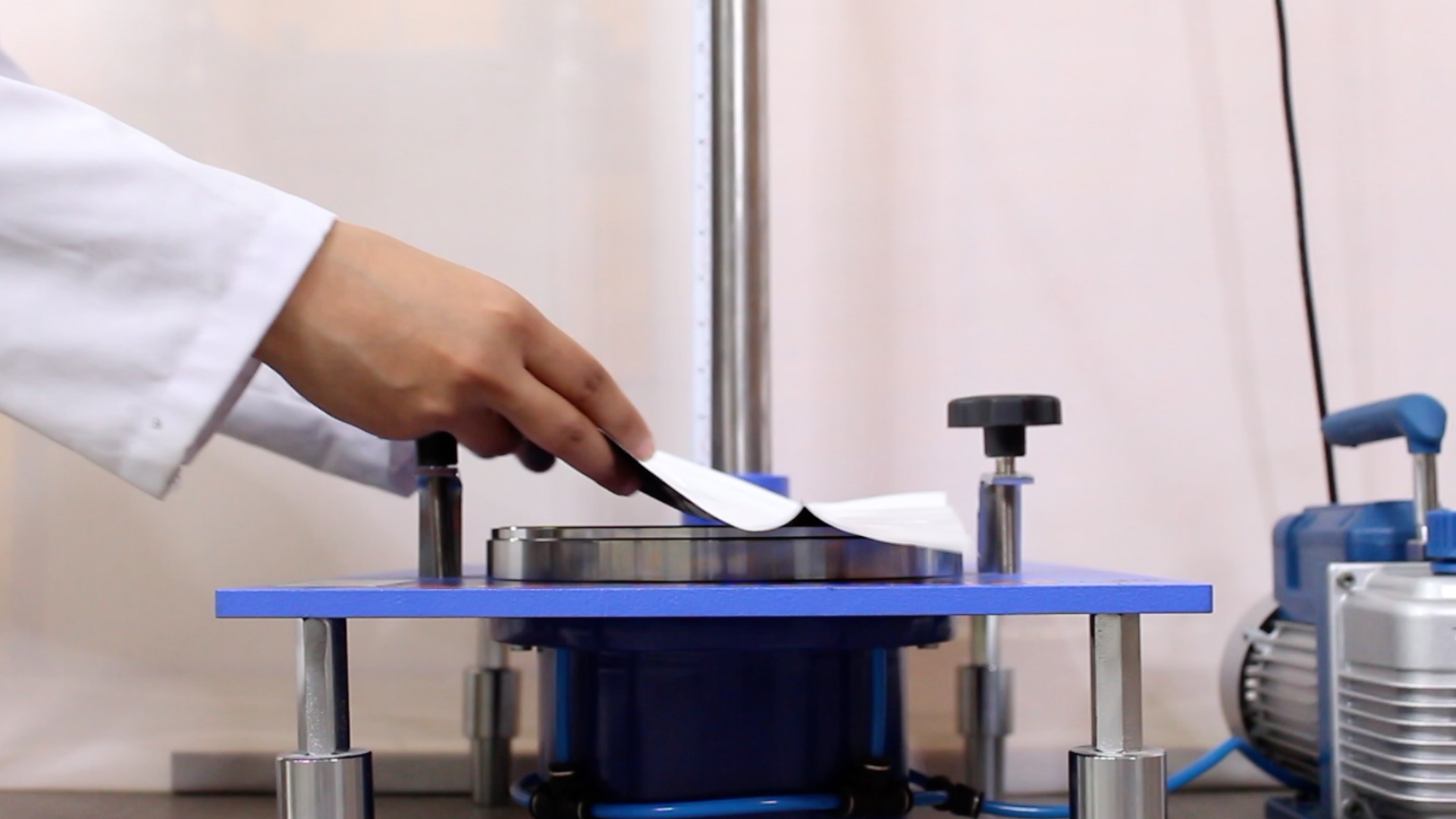

Setup: The test sample is fixed inside the machine.

Dart Release: A dart weighing a few grams is released from a defined height.

Measurement at Impact: When it strikes, the machine measures the amount of energy absorbed by the material as well as the amount of damage it suffers.

Data Analysis: Results are given in joules or other units of energy, so manufacturers can determine whether their product meets the standard.

Falling dart impact testers are designed to mimic real-life conditions, making them highly suitable for a manufacturer. This method can give you an idea of how your packaging materials are going to behave under normal stressors, and this varies significantly depending on the industry. That is, food packaging might have to deal with different impacts than electronic packaging.

When selecting a dart impact tester, several of these technical specifications should be taken into account.

Dart Weight: The higher the dart weight, then the greater the impact. This means the converse is in a lower weight as it relates to less severe testing conditions.

Drop Height: A drop height can be varied to seek flexibility in testing.

Energy Absorbed: Ensure that the tester will deliver accurate measurements of the energy absorbed during impact since the data is very important in the assessment of material performance.

Sample Size Acceptance: Verify if the tester can accommodate the sample size you have for your packaging material.

Buying a dart impact tester is a major decision for the manufacturer. The cost for a dart impact tester varies with brand and model, depending on its different features and capabilities. Basic versions can start at a little over $3,000, whereas high-end versions of fully automated models may go above $10,000. Determine your test needs and have a budget-friendly model that functions well.

Quality assurance: The reliability of your packaging will be ensured every time with regular testing; this can greatly reduce complaints from customers.

Material development: New material or design testing allows manufacturers to innovate better and save an enormously considerable amount of time while bringing new products to the market.

Savings: A dart tester will save you much money in the long run since you will experience fewer returns and damages caused by poor packaging.

Compliance with Standards: Most industries have strict regulations involving packaging performance. With a dart impact tester, you will be in full compliance at all times.

A company that stands out in this universe of dart impact testers is Presto. Presto is a company that specialises in selling quality testing instruments and has available models for most industrial requirements. Their dart impact testers are both accurate and easy to use so can work well with any manufacturer's quality control process. Moreover, Presto provides great customer service to help customers choose the right model and make the most of their investment.

Q1: What type of materials may be tested using a dart impact tester?

A dart impact tester is most commonly used with plastic films, but it has very versatile applications with materials such as paper and cardboard.

2. How frequently do I have to run tests with a dart impact tester?

It's highly recommended that you regularly test, especially after you change materials, suppliers, or packaging design. The frequency of testing will ensure you continue living by the book when it comes to matters of safety compliance.

3. Do I use this dart impact tester for other purposes?

Even though mainly for packaging material, in R&D some manufacturers use a dart impact tester to assess a new formulation.

4. What are factors that may influence dart impact testing results?

Some of the factors which definitely influence the results include the age of the test specimen, temperature, and humidity. The testing environment shall be well-controlled to offer the most reliable results.

5. Are there specific industry standards in regard to dart impact testing?

Yes, and of course, each industry has its own standards in itself. For example, plastics have an ASTM D1709 standard. Get to know the standards applicable to your area of action.

Quality packaging should not be sacrificed in any competitive landscape production case. Manufacturers can gain tremendous insight into the durability and resistance of their packaging materials by using a dart impact tester. This will improve not only the safety of the products but also increase the satisfaction of customers with the brand.

As you go ahead and consider incorporating a dart impact tester into your quality control, do not forget that the variety of models and frequent tests are vital. By equipping yourself with the right tools, it is possible to ensure the packaging solutions that take its end toughness to the level required, and thereby push your business forward in a challenging marketplace.

Are you ready to step it up a notch with the quality of your package? That probably has to be the best investment ever needed in manufacturing processes: the acquisition of a dart impact tester!

or inquiries about the dart impact tester price, please contact us at Phone: +91 9210 903 903 or via Email: info@prestogroup.com for detailed information and assistance.