PET products and preforms are used on a large scale in different production verticals such as food and beverages, bottling plants, pharmaceutical, chemical manufacturing industries and many more. All the applications in which PET products are used are very crucial in natures and a minor defect in the PET products that damage the complete lot. This damage can sometimes lead to fatal accidents. Therefore, the manufacturers in PET & Preform manufacturing industries must test the quality of the products they manufacture using premium quality of testing instruments. This strategy of using testing machines not only helps to maintain the quality of the product but also helps to satisfy the customers with the premium quality of the material.

PET products and preforms are used on a large scale in different production verticals such as food and beverages, bottling plants, pharmaceutical, chemical manufacturing industries and many more. All the applications in which PET products are used are very crucial in natures and a minor defect in the PET products that damage the complete lot. This damage can sometimes lead to fatal accidents. Therefore, the manufacturers in PET & Preform manufacturing industries must test the quality of the products they manufacture using premium quality of testing instruments. This strategy of using testing machines not only helps to maintain the quality of the product but also helps to satisfy the customers with the premium quality of the material.

Properties of Pet Bottles that Affect Its Quality

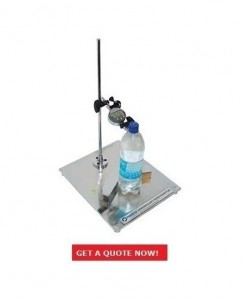

The quality of the PET products can be tested by measuring the properties of the PET products such as transparency, leakage, perpendicularity, shape, size, alignment, seal strength, compression strength, torque and many more. Out of these properties, the perpendicularity of the bottles is the main property that explains that whether the bottle is defected or safe to use. If the balancing of the bottle is not up to the mark, it will let the bottle to trip again and again. This can also lead the bottles to leak and can cause many accidents. This property of bottles can be tested with the help of high-quality of Bottle design and Shape Tester. The testing machine measures the perpendicularity of the bottle from all the ends that help to ensure the balancing of the bottles.

Measure Bottles Perpendicularity with Presto Bottle design and Shape Tester

Presto Stantest offers the best quality of Bottle design and Shape Tester, which helps to measure the quality and perpendicularity of the PET bottles. The testing device is designed as per the standards that are provided by various standardization authorities. The test device offers highly accurate test results. To know more about the device, visit: www.prestogroup.com/

Related Blogs

Dead Weight Tester ensures ultra-precise pressure calibration using known weights and a piston system. It's widely used in aerospace, oil, and manufacturing for accuracy up to 0.005%.

Discover high-performance deep freezers for medical laboratories, ensuring safe storage of vaccines, samples, and sensitive biological materials.

Discover why testing material toughness is crucial in quality control and safety. Learn how Izod Charpy testers accurately measure impact resistance and ensure product reliability.