Gaurav Malhotra-Testing Instrument Expert

23-12-2024

The melt flow index tester is one of the most accurate instruments used in measuring polymer flow properties, It offers information to optimize production processes. This blog covers the technical aspects of melt flow rate testing, how an index from melt flow is important, and how a melt flow rate tester acts as an instrument of significant importance in the plastics industry.

The MFI is a highly significant indicator of a polymer's flowability when put under high temperatures and pressure. The test measures the amount of material that flows through a small orifice in a given time under set conditions. The MFI will be able to yield important information about molecular weight distribution, viscosity, and overall flow characteristics of the polymer critical in determining if the polymer will be suited for various applications.

High melt flow rate MFR values indicate low viscosity; thus, the polymer flows easily when heated. Conversely, low MFR values indicate higher viscosity and more resistance to flow.

It is highly essential to understand MFR for the selection of materials and optimizing the process. For instance, when plastic is processed by injection moulding or extrusion techniques, the knowledge of the value of MFR of that polymer will decide the suitable processing conditions. It is also helpful in designing equipment and predicting the behaviour of processing under different conditions of temperature and pressure settings.

Presto is a leading testing instruments manufacturer. With over 40 years of experience and expertise, Presto believes in providing the best to its customers. We are a client-oriented organization with end-to-end support. We serve to a vast clientele of 11000 companies, join the family today!

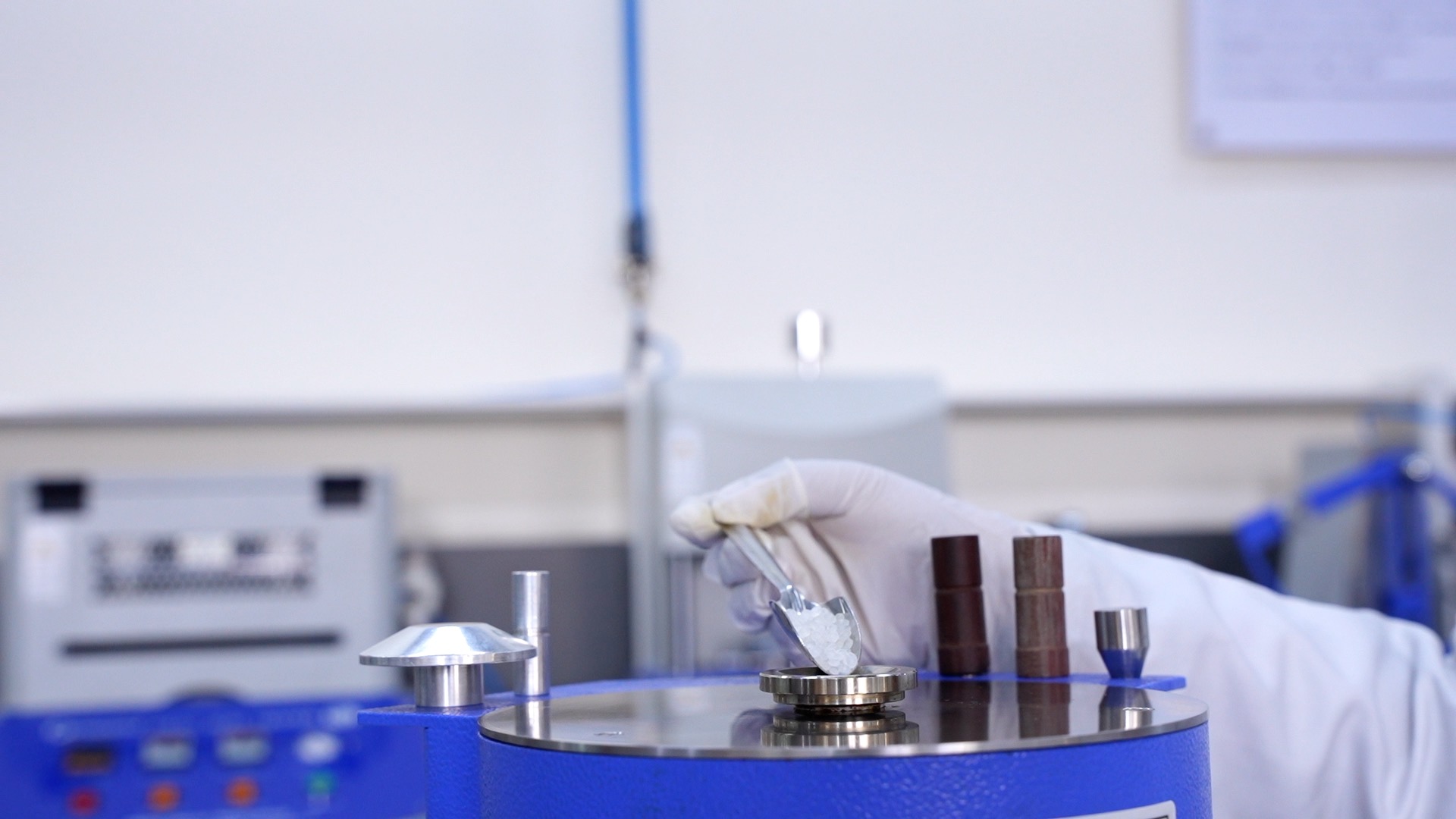

Temperature Control: The accuracy of temperature control ensures that the polymer sample is processed under standard conditions.

Load Application: The right application of load ensures uniformity in the extrusion process, contributing to more accurate MFI measurements.

Advanced testers include digital systems that facilitate the recording and reporting of data in real time, hence aiding the monitoring of trends as well as quality assurance checks.

Ease of Use: User-friendly interfaces with intuitive software enable quick operation even for a non-technical user.

The formula for Melt Flow Rate calculation

The formula for computing the MFI is

MFI= Weight of polymer extruded (grams)/ Time taken (minutes)

The weight of the extruded material is measured over some time; hence, this MFI is expressed in terms of grams per 10 minutes. Then it's utilized to judge the flow properties of the polymer; the more the value of MFI, the less the viscosity.

Beyond being an MFI measuring apparatus, the plastic MFI tester is a multi-faceted instrument, which has been useful in the characterization of many polymers. It also has applications in giving an impression of the molecular structure and the processing behavior of plastics, besides just testing. The use of the tester in testing the flow characteristics of resins, alloys, and the like, which undergo some form of thermal processing, is one such example.

There are several more important parameters that, while not normally measured simultaneously with MFI, may sometimes be reported; among them is melt volume index, or MVI. This includes the consideration of volume polymer extruded in the course of a test, thereby giving some more information regarding material flowability, particularly helpful for those that show large viscosity change through processing.

Consistency is the word of polymer manufacturing. MFI testing is a crucial step in quality control since it directly gives insight into the material's processability. Melting flow rate measurement will give assurance that the polymer batch will act the same downstream application as extrusion, injection moulding, or blow moulding.

Usually, results from this test are applied to assess

Material uniformity: The flow behaviour of each lot of polymer is the same.

Process optimisation: Parameters in the process are altered to replicate the flow behaviour of the material.

End-use performance: Predicts how the material will behave at the point of final use.

MFI is given as the rate at which a polymer melts and flows. MFR is the value provided by the MFI measurement, which is the quantity of material extruded within some specified time under standard testing conditions.

The melt flow rate tells about how viscous the polymer is and how it flows under some specific conditions. It becomes highly important in optimizing the process of extrusion, injection moulding, and blow moulding.

Yes, MFI is a great measure to compare the flow properties of different materials. It helps manufacturers to decide the right material for specific applications.

MFI tests should be run at regular stages of production to ensure regularity and quality. Test frequency will depend on a production schedule and material batch sizes.

The melt volume index MVI is additional information with respect to the flowability of a polymer by providing an indication of the material volume that has been extruded in addition to determining the flow behaviour.

The Melt Flow Index Tester is more than just a measuring equipment it is a critical instrument in the polymer and plastics industry for quality control and optimization of the process. MFI testing provides detailed insights into the flow characteristics of the material, which helps the manufacturers select the correct polymers for their application and ensures consistency in the production process. As the technologies become more rapid in the previous years, the significance of MFI testing in the optimization of polymer processes and product quality has increased much, promising a new level of precision and reliability.

Phone: +91 9210 903 903

Mail: info@prestogroup.com