Vishal Malhotra-Testing Instrument Expert

24-4-2025

It's a world where the labels on your favourite products detach themselves, where the plastic cover on your new device bubbles and breaks off, or where the medical device's critical seals fail when subjected to pressure. It's not just frustrating; it can be the cause of customer complaint, product recall, and even safety hazards. The quiet guardian of these failures? Peel strength testing.

With the competitive manufacturing landscape of the current era, reliability and shelf life of bonded products are issues of paramount concern. Whether packaging adhesives, electronic coatings, or auto part seals, bond strength – i.e., peel resistance – is a do-or-die quality parameter. That is where the peel strength tester, or adhesive bond strength Analyzer or peel testing machine assumes prominence.

But what exactly is peel strength, how do you actually test it? And what is the Peel strength formula? Well, join us for a journey around the lovely adhesion testing world and find out the secrets to getting your products to last the test of time (and the random tug).

Imagine a highly reputable electronics manufacturer with a runaway level of consumer complaints. Its protective screen covers on its premium smartphone screens were detaching far too early, even before scheduled removal by the user. Not only was it damaging the looks, but also calling into question the whole process of quality control.

The engineering staff had originally suspected a failure of the adhesive. But simply replacing a fresh adhesive was not a long-term fix without addressing the root cause. They required a measurable parameter to assess the functioning of the adhesive – they had to know its peel strength.

Enter the peel strength test. Using a highly accurate peel testing machine, the engineers could measure in a controlled manner the force needed to peel the cover film off the display surface at a particular angle and speed. From this information, they gained important insight into the integrity of the bond.

Peel strength is an indication of the amount of force which is required to gradually peel two flexible bonded materials slowly apart. It's similar to peeling a sticker off a surface gradually. The pressure you experience is due to the adhesive forces at work.

The equation for peel strength, though not a single one because of differences in the Peel strength test method and material properties, in general, relates the measured force to the width of the bonded interface. The value calculated is a reflection of the resistance of the bond against peeling separation.

For the provision of unity and comparability across various manufacturers and industries, standard test methods are of the utmost significance. Entities such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) have created general peel strength test standards.

These test standards carefully define test equipment, test setup, peeling angle (commonly 90° or 180°), test speed, and testing procedures for the data analysis. Conforming to these peel strength test standards can guarantee that data derived from a material peel test instrument in Meerut could very well be interchanged with outcomes from a comparable test in, for instance, Germany or America.

The peel strength unit tends to provide the force used per unit of bond width.

Understanding of the peel strength unit is elementary to the conversion of test values and comparison of adhesive properties between two or more disparate materials.

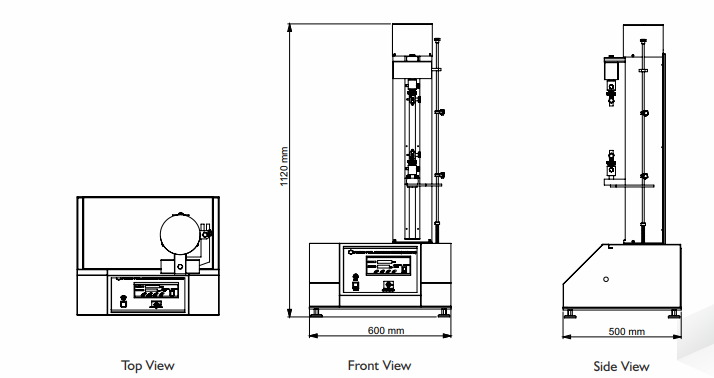

Today's adhesion testers are sophisticated instruments with precise motion control, high-precision load cells and user-friendly software for acquiring data. A Peel Testing Machine is an extremely advanced piece of equipment that can perform a variety of different peel tests like 90-degree peel and 180-degree peel and even T-peel tests in a wide variety of applications.

In addition, there are environment simulation chambers for testing peel strength at various temperatures and humidity, which give an enhanced understanding of the functioning of the adhesive in practical conditions.

Frequently Asked Questions About Peel Strength Testers

Q1. What is peel strength testing?

A1. Peel strength testing is a process applied to determine the force needed to peel two flexible bonded materials apart. Peel strength measures the ability of the adhesive bond to withstand peeling forces and gives information of paramount importance concerning the bond's integrity and durability.

Q2. How do you calculate peel strength?

A2. Peel strength is typically calculated by dividing the average peel force to separate the materials by the width of the bonded interface. The particular equation used may depend on the test standard and the geometry of the test specimen. Typically, it is defined as:

Peel Strength = Average Peel Force/ Width of Bond

Q3. How is the ISO test for peel strength?

A3. There are some ISO standards that may be used to apply to testing peel strength, depending on use and materials that will be tested. All of which you can find on the internet.

Q4. What is the ASTM standard for peel strength?

A4. ASTM also possesses a number of standards for measuring peel strength based on application and materials. All of which you can find on the web.

The Role of Peel Strength Testing That Just Can't Be Evaded From inhibiting labelling to confirming the safety of life-saving healthcare products, peel strength testing is a key competency for manufacturers across an enormous spectrum of industries. By understanding the physics of peel strength, employing recognized test procedures, and employing suitable peel testing equipment, companies can confirm the dependability, quality, and endurance of their bonded products. The simple peel-off process hides a subtle ballet of forces, and the measuring technology is the key to making products that stick like never before.

Looking to improve product consistency and ensure strong, reliable bonds? Discover the benefits of our high-performance Peel Strength Testers today.

Want the best Peel Strength Tester Price? Call us now at +91 9210 903 903 or email info@prestogroup.com for a free consultation!

Related Blogs

The Vacuum Leak Tester serves as a quality control instrument which uses vacuum pressure to detect package leaks on test specimens.

Explore how a humidity chamber operates with insights into its working principle, detailed diagram, and practical applications across industries like packaging, electronics, and pharmaceuticals.

Optimize packaging durability with Top Load Testers. Evaluate the vertical load a container can withstand before buckling or deformation occurs.