Gaurav Malhotra

19-9-2024

One manufacturer, product designer, or engineer also knows that endurance testing is crucial in determining the longevity of materials. But have you ever thought about how you can be sure whether your products can take real-world stresses? That is where the impact testing machine comes in. Impact Testers: Types and Choosing the Right ONE for You

This blog will take you through this fabulous world of impact testing and break down the different kinds of impact testers that exist so you can determine which one to use.

But before we go into the details, let's step back and ask a very simple question: What is impact testing? Impact testing measures a material's ability to absorb energy due to a struck force. This is important in gaining knowledge of how a material will behave under sudden forces or shocks, which could be as slight as a dropped object or a collision.

Do you, therefore, test your products for impact resistance? Which type of tests are you doing if you do?

Types of Impact Testing Machines

Many such impact testing machines exist; one of the most recognized ones is the Charpy impact tester. It is named after the French engineer Georges Charpy, and it measures the impact energy of the absorption at fracture by the material under test. A notched specimen is struck in this test by a pendulum hammer, from which the absorbed energy is obtained. This test is particularly suitable for materials to be used at fluctuating temperatures or subjected to any kind of sudden impact.

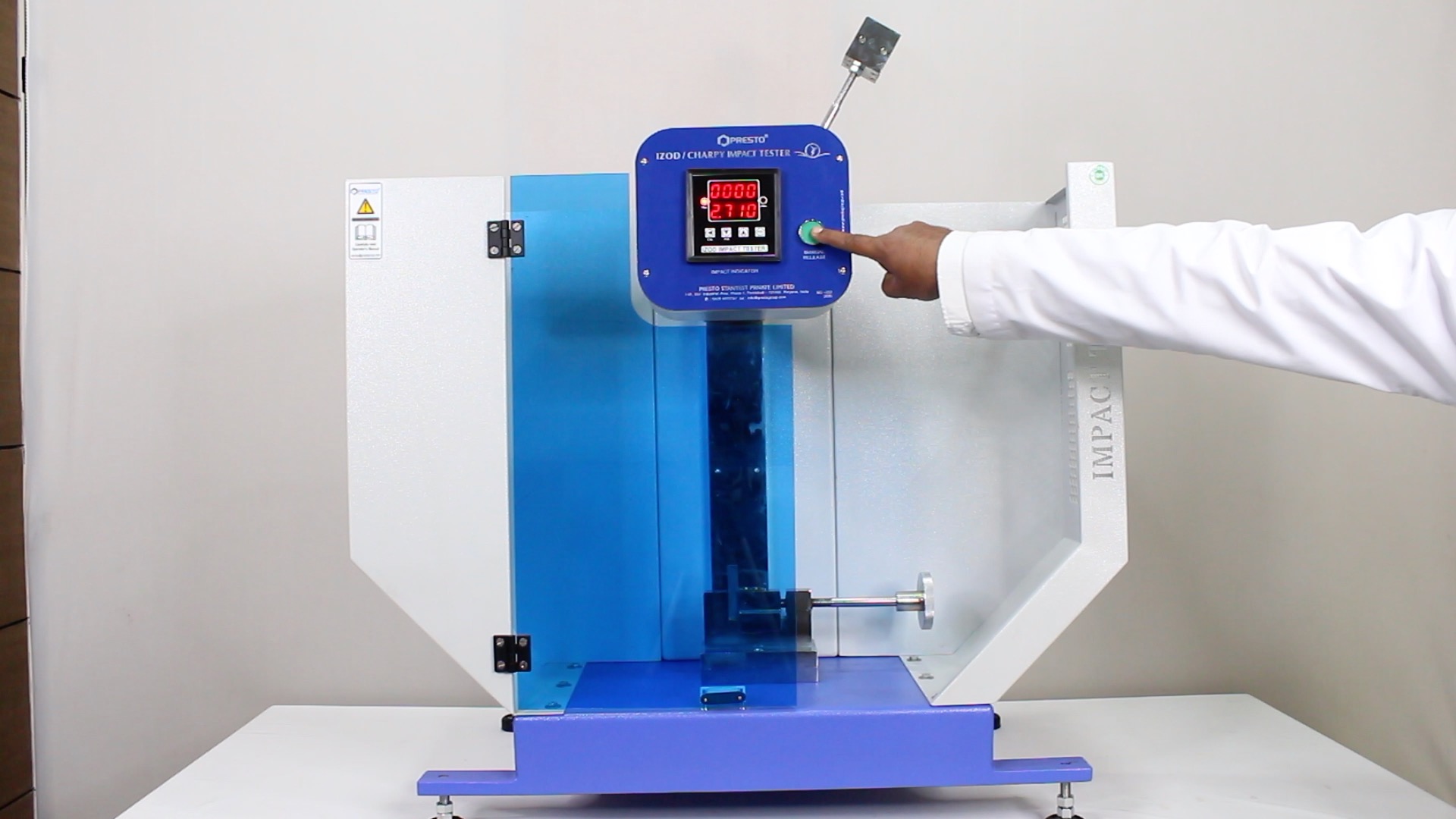

Izod impact testing machine is also somehow related to Charpy but the setup is somewhat different. The Izod test will hold the specimen in a vertical position, strike it with a notched specimen using a pendulum hammer that falls horizontally and finally examine the ability of materials against bending forces.

Key Things to Consider When Selecting an Impact Test Machine

Measurement Resolution

If you are simply choosing one for the procurement of an impact testing machine, precision and accuracy will definitely be a crucial consideration. Reliability and repeatability of your tests are very important. A good machine will ensure that your testing data consistently proves to be accurate and very useful in material performance-related decisions.

Types of Materials and Test Requirements

Different machines would be more appropriate for different types of materials or tests. For example, the Charpy impact tester tends to be used more often on metals, but it can be used on plastics too. It just depends on what type of materials you're working with and what the needs of your tests are.

What do you commonly work with? Are there special testing requirements that might impact your selection of an impact testing machine?

Buy and Cost

The most vital aspect is the price and purchase of an impact testing machine. Impact testing machines range in cost from one to another depending on what the features, precision, and brand may be. It may be obligatory to have a quality machine for high-precision testing but still one that fits your budget.

How much have you gauged the occurrence of price differences in impact testing machines? What should be most important to you while attempting to balance cost against functionality?

Why Presto

If you are investing in one of these machines, then there is a need to look at Presto. Presto is a company that really excels in producing reliable, high-quality equipment for testing. The high-strength Presto impact testing machines, like the Charpy and the Izod testers, will give you that strength and stability when you require it for your industrial-scale operations. The machines ensure you get accurate, repeatable results so you can monitor how well your materials stand against impact.

FAQs

What is the difference between the Charpy and the Izod impact test?

The difference in orientation by which the specimen to be tested has to be held and supported is the main difference between both tests. In the Charpy test, the specimen is supported on horizontal supporting elements and struck at the middle of its length. In the Izod test, it is directly supported vertically, and the impact is upon one end. This would provide a basis for differences based on the mode suited to different materials.

How often should impact testing be conducted?

The frequency of impact testing depends on your production cycle and the material specification. Conduct it more frequently, in case you are going to make changes in your material or your production process so that it can be ensured constantly that what quality and performance you are getting.

Can impact testing machines work for all types of materials?

All kinds of materials - metals, plastics, and composites - can be accommodated in an impact testing machine. However, the suitability of a particular kind of machine depends on the kind of material and the nature of the impact test required.

What is the best thing I should do to be assured that my impact testing machine delivers accurate results?

Regular calibration and maintenance are quite necessary to keep the impact testing machine at its utmost accuracy. The time for calibration would be according to the instructions of the manufacturer, and that is also based on a routine checkup that is completed in a given time frame.

The impact testing should confirm whether your products can withstand real-world stresses. In whichever it may be whether on the Charpy impact tester, an Izod impact testing machine or anything else, it will first be important to make sure that you have a device which suits the need of accuracy you want in testing, the kinds of materials you'll be testing to know their appropriateness and your budget.

Do you currently use impact testing machines in your process? What do you think of it so far? You have not tried impact testing, yet. What are some of the biggest concerns or questions you have?

Call us at +91 9210 903 903 or simply leave an email at info@prestogroup.com

Include any questions or comments you may have below. And we'll keep the conversation going so all your products are as tough as they need to be!

Related Blogs

Salt spray test checks corrosion resistance of materials using a salt spray chamber. Essential for quality control in coatings, metals, and finishes.

Hot Air Oven uses dry heat for sterilizing glassware and metal tools, while an Autoclave uses steam under pressure—ideal for liquids and medical items.

GSM of fabric (Grams per Square Meter) indicates fabric weight and thickness. Higher GSM means denser, heavier fabric; lower GSM means lighter, thinner fabric.