Identify Weaknesses in the Packaging Design with the Box Compression Tester

Packing sensitive or perishable items into cartons or corrugated boxes is something that is very widely practiced all around the world. These corrugated boxes have truly been an unbeatable invention when it comes to packing items for transit & storage purposes. These cartons not only save space for storage but also ensure the safety of the materials packed inside to a greater extent.

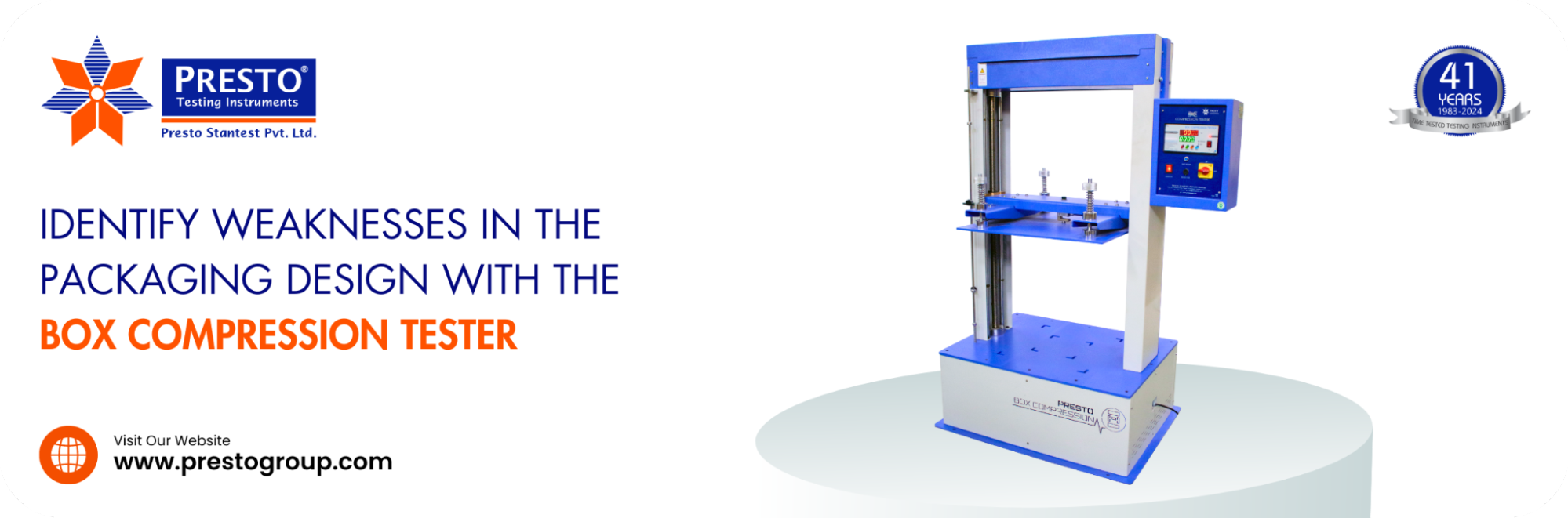

One of the highly valued testing measures is to assess the compression strength of a carton. This can be done with the help of a box compression tester designed by the Presto Group.

This lab testing instrument is designed to identify the weaknesses in the packaging design of corrugated boxes, will ensure the safety & security of the packaged items and will also provide a sense of assurance in case of shipping & storage of the items packed within. The safe & secure delivery of these items ensures brand building by maximum customer support.

It is important to get through the working mechanism of this highly ergonomic instrument for a better understanding as well as for further knowledge.

Box Compression Tester - Working Mechanism

The Box compression tester is a lab testing instrument that simulates the real-life stacking of boxes which is often seen during storage of products. The instrument compresses the box and identifies its strength against compression.

The testing procedure begins with placing the corrugated box at the dedicated sample positioning platform labeled with cutouts for accurate & precise placement.

After the specimen is placed as per the cutouts, the motorized platform situated above the specimen starts moving downwards at a designated speed of 12.7mm per minute, regulating as per the compliance of the designated standards.

The downward movement of the motorized platform is ensured by a circular lead screw for smooth operation. The motorized platform starts compressing the specimen at a speed of 12.7mm per minute with a weight of 500 KgF / 1000 KgF (customizable as per the requirement).

After withstanding a certain amount of load, the box starts experiencing deformity, exposing the weaknesses of the corrugated box. The max load that the box was able to withstand and the deformity after that is indicated directly on the microprocessor-based digital display.

After achieving the maximum deformity & compression, the motorized platform comes back to its original position due to the provision of limit switches added by the box compression tester manufacturer to avoid any sort of discrepancies or hazards.

The operator of the instrument can simply record the results depicted on the microprocessor-based display for correct and accurate evaluation of the corrugated box.

Besides an ergonomic & user-friendly construction, the instrument is designed with highly futuristic as well as brilliantly thought incorporation of features that contribute towards the accuracy-driven approach of the equipment. If you want to know more briefly about the working of a box compression tester then you can also consult with our technical team of experts.

Features of Box Compression Tester

The box compression tester manufacturer has made sure to imbibe all the necessary features for precise testing results and for the promotion of single-handed testing.

The first & foremost feature of the lab testing equipment is the incorporation of the limit switches to avoid any jeopardies due to overtravel and thus prevent damages.

The base plate for the placement of the specimen is constructed to be extremely firm and strong with a rugged surface to ensure that the specimen does not slip during the course of testing. The strong base plate also has labeled cutouts for accurate positioning of the sample.

The instrument promotes single-handed testing with the help of father touch controls that simplify the testing module of the equipment.

The compression plate or the motorized platform is designed to exert uniform force over the specimen in order to achieve maximum levels of accuracy with the help of the box compression test.

The instrument also offers a microprocessor-based display instilled with Tare & Peak hold buttons, depicting the maximum load & deformity of the instrument. The combination of these two makes it extremely simple for the operator to keep track of the data. However, to enhance data keeping 7 keep track, you can always go for the box compression tester computerized.

The instrument is made with high-quality, anti-corrosive material i.e. lab grade stainless steel & mild steel which is coated with 7-layered powder paint to ensure longevity and durability of the instrument for the long term.

There are certain frequently asked questions regarding the box compression tester by manufacturers from various industries.

FAQs About the Box Compression Tester

How does the Box Compression Tester simulate real-life stacking?

Ans. The box compression tester simulates the real-life stacking of materials by implying a buckling load on the specimen from the top with the help of a motorized platform associated with the circular lead screw for smooth movement.

What is the end result derivation of the box compression tester digital or box compression tester computerized?

Ans. The conclusion of the box compression tester is to determine the maximum load that the specimen was able to withstand before getting deformed. However, the instrument is so advanced that it also indicates the deformity that the specimen experienced.

What standards are satisfied by this box compression tester?

Ans. The instrument is constructed in compliance with ASTM D642, ASTM D4169, TAPPI T804, ISO 12048 & JIS ZO212.

Get Your Hands on the Box Compression Tester And Say Goodbye to box compression issues!

To identify weaknesses in the packaging material, get your hands on the highly valued box compression tester. To seek further information & get acknowledged about the box compression tester price, you can simply look at our website.

Do not wait any longer and place an order right now at +91 9210903903. If you want to express your feelings about the instrument, you can write to us at info@prestogroup.com.

The Presto Group would love to serve your manufacturing needs in assuring maximum quality to all the consumers.

you may also like

- The Ultimate Guide to Universal Testing Machines (UTM)

- Guide to Bursting Strength Tester: Working, Benefits & Price

- Ultimate Guide to Melt Flow Index Tester: Operations, Advantages, and Uses

- A Complete Guide to Box Compression Tester: Methods & Applications

- Hot air oven not working? Common problems & fixing issues

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Get a Quote