Vishal Malhotra-Testing Instrument Expert

19-4-2025

The execution of environmental tests proves essential for product development, together with quality assurance activities and research activities. The field requires humidity chambers as essential tools, alongside their purpose as environmental chambers to imitate actual atmospheric conditions between humidity and temperature.

Organizations depend mainly on humidity chambers to measure how materials function when they encounter changing environmental conditions during durability and reliability tests. Brown and white bayonet joints enable these devices to successfully serve various industries such as pharmaceuticals and electronics and textiles, and packaging. This blog will explain the operating concept of humidity chambers while presenting diagrams as well as applications and relevant HSN codes and their crucial role in laboratory work.

A humidity chamber operates as an instrumentation device which controls both temperature and humidity conditions over time periods. The primary purpose of these chambers is to monitor material responses to changing environmental factors.

As the heart of environmental chamber systems, this tool evaluates the effects that humidity has on several critical factors.

Common Industries Using Humidity Chambers:

Humidity Chamber Working Principle

Every application requires a humidity chamber with the appropriate working principle, for which reason understanding these fundamentals helps users select the right model.

Main Components Involved:

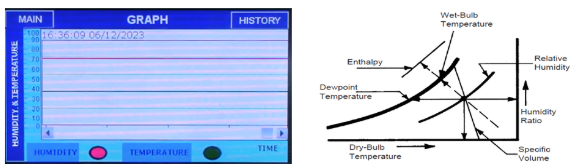

The science behind the working of a humidity chamber is thermodynamically operated and humidity controls with Wet and dry bulb thermometers.

These are also some prominent standards for performing humidity test ASTM D 618, ASTM D 1776, ASTM D 885, and ASTM D 7269.

| Material | Temperature | Humidity | ASTM standard |

| Plastic | 23°C ± 2°C | 50% ± 5% | D 618 |

| Textile | 21°C ± 1°C | 65% ± 5% | D 1776 |

| Rayon, Polyster, Polyamide | 20°C ± 2°C | 65% ± 2% | D 885 |

| Aramide | 20°C ± 2°C | 65% ± 2% | D 7269 |

5. How to perform testing in a Humidity chamber?

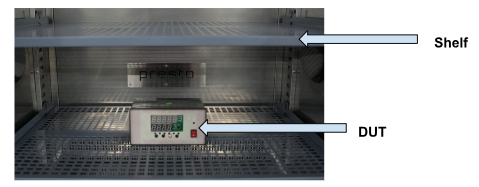

Preferring standard conditions as per product will be the best way to analyze the atmospheric simulation on the device under test (DUT). There are many IEC standards for electrical components like IEC 60068-2-78 and ASTM standards for coating, textiles and other industries that want to perform testing like ASTM D1776. Many ISO standards can also work for it.

Let us understand how to perform testing as per IEC 60068-2-78 for electronic components.

By referring to a researched standard it will help in comparing the items more formally and scientifically. This helps in ensuring correct results. The Standard mentions a severity condition with duration to be provided to DUT.

| (30 ± 2) °C | (93 ± 3) % RH |

| (30 ± 2) °C | (85 ± 3) % RH |

| (40 ± 2) °C | (93 ± 3) % RH |

| (40 ± 2) °C | (85 ± 3) % RH |

Preferred duration of testing are: 12 h; 16 h; 24 h; and 2, 4, 10, 21 or 56 days.

The Presto’s Temperature and humidity chambers are capable of maintaining relative humidity 20 % to 95% and with temperature controlling of -70°C to 180°C. The sizes are available as per DUT and specimen size of the industry.

6. Factors affecting the accurate humidity testing

The accuracy and uniformity of environmental simulation depend on many factors like inner chamber material, calibration of parameters, and standardized conditions to be set. The accessories and units used should be high-grade.

• Inner chamber material construction: High-grade Stainless steel body with 304 or 306 with polyurethane foam (PUF) insulation can help in maintenance and uniformity.

INNER VIEW OF PRESTO HUMIDITY CHAMBER

Temperature and humidity sensors: Using Nichrome heaters and high-grade refrigerants in compressors can ensure sustainable and accurate environmental conditions. PT 100 advanced sensor uniformly analyses the precise temperatures in the chamber.

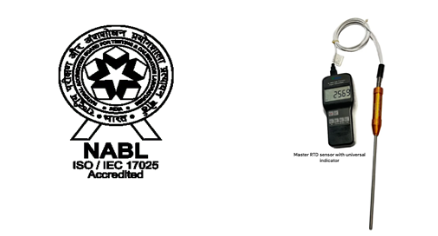

• Calibrated machine: The parameters temperature and humidity determine the efficiency and accuracy in test performance which is possible only in a calibrated machine. Master temperature sensors are used to calibrate the sensors used in machines and it is required to have accreditation of an institution working for master gauges. Hence, the National Accreditation Board for Testing and Calibration laboratories is an organization to audit the parameters.

Working Process Explained:

An illustration of the internal humidity chamber depicts the steam humidifier system together with sensor devices, while showing necessary air movement elements.

The block diagram of this humidity chamber includes essential parts that include:

Temperature & Humidity Sensors

Users who understand this arrangement will achieve superior equipment maintenance, which ensures their testing methods remain accurate and consistent.

Humidity chambers offer versatile testing capabilities across various sectors. Such are the most typical applications of humidity chambers:

1. Accelerated Aging Tests

The device predicts product lifespan by performing simulations of both material exposure to high heat and prolonged humidity conditions.

2. Packaging Integrity Tests

Packaging undergoes testing as it withstands the challenges of humidity impact during distribution and storage periods.

3. Electronics Testing

The system determines the risk of corrosion, short circuiting and material swelling in PCBs and electronic components.

4. Pharmaceutical Stability Testing

These test procedures follow ICH guidelines to establish product shelf life, together with performance characteristics needed under regulated storage environments.

5. Automotive Component Testing

A test procedure checks the ability of dashboard elements and sensors, and wiring to resist weather conditions.

The laboratory field frequently uses humidity chambers for their exact control of testing environments and their ability to deliver dependable results. These devices serve as fundamental assets during research work and satisfy compliance requirements.

Key Laboratory Applications:

Textile Labs: Colorfastness testing, shrinkage analysis, and fabric performance under moisture.

The laboratory models of humidity chambers at Presto offer the following features:

The industrial processes utilize humidity chambers as essential equipment that confirms products satisfy criteria for safety and quality, and durability standards. Knowledge of this instrument’s main features through its working principle and diagram, together with applications in labs and its HSN code, will help increase the reliability of your testing methods.

Looking for the best Humidity Chamber price at competitive rates? Get in touch with us today!

We’ll help you find the ideal Humidity Chamber price and the perfect solution!

Related Blogs

Optimize packaging durability with Top Load Testers. Evaluate the vertical load a container can withstand before buckling or deformation occurs.

A polariscope is a machine that uses a unique light to see how other things modify light. It usually consists of two polarizing filters, or polarizers, positioned in a particular way.

A Hot Air Oven uses dry heat to sterilize, dry, or heat materials. Widely used in labs, hospitals, and factories, it ensures safe, efficient, and even heat distribution.