Gaurav Malhotra-Testing Instrument Expert

19-2-2025

Need to fix the issues occurring in the Hot air oven? Learn how to fix the issues and get service-related expert tips for rectifying malfunctioning faults in your laboratory hot air oven or industrial hot air oven to use it efficiently.

Contents:

A Hot air oven is a laboratory or industrial testing instrument that works on the convectional heating principle and generates dry heat from an air blower at a specific temperature. It helps in multipurpose ways like dry heating the specimen, conditioning the specimen, and sterilization purposes in microbiological industries.

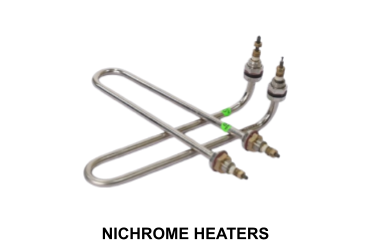

The heating element is faulty: Many times, a heating element is the main reason behind the no heating; either it's broken inside or in the malfunctioning stage. A good quality heating element is important, which possesses minimal corrosive degradation and has a high melting point.

Solution: Change the heating element. Try using an advanced and more durable heating element like Nichrome heating elements. Check the heating with the help of a multimeter.

SSR malfunctioning: One of the main issues can be a failure of SSR, which gives input to the PID controller, and heating is then generated.

Solution: The issue can be resolved by checking the wires, control system, and warranty in SSR, i.e., Solid State Relay.

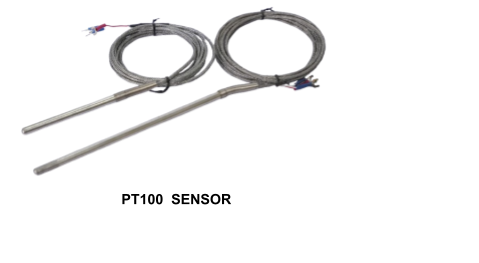

Temperature sensor malfunctioning: A good quality, precise temperature sensor with its proper alignment maintains stability and uniformity in temperature sensing throughout the chamber. The damage to the Temperature sensor can also be a reason for fluctuations. Hence, a calibrated sensor is a must for laboratory or industrial hot air ovens.

Solution: Properly align the temperature sensor. Don't use a faulty temperature sensor. Focus on the cleaning of the sensor, as debris over the sensor can change readings.

One of the most crucial factors behind inaccurate temperature readings is the stable environmental factors in the testing area. Ambient environmental conditions like 27 degrees with +/-2 degrees and Relative humidity of 95% +/- 5% are crucial to maintain stable conditions

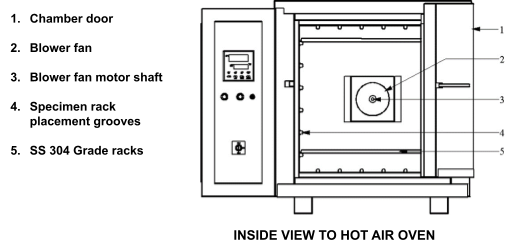

Possible reasons for failure in air blower could be:

Mismatch in the air blower & heating element

Noisy air blower: Dirt, and loose components in the air blower

Overheating: Poor ventilation, power supply issues (steady flow of current is required during the process)

Solutions: Arrange a new air blower if the components have undergone depreciation. Manage the power supply and check it during the initial stages with the multimeter. It is important to have sufficient ventilation.

A steady flow of power supply not coming: It is important throughout the test to have an appropriate power supply. Short circuits, non-uniformity, and fluctuation in temperature can occur due to power supply issues.

Solution: Check whether the power needs a single-phase or three-phase supply, The socket should be capable enough to hold it. Earthing should be a maximum of 3 Volts and that should be checked well.

PID i.e. Proportional Integral Derivative control is the feedback loop that works on the SSR command.

Parameters reset: Manufacture sets some control factors on which the whole functioning is understood by the PID, changes in internal setting may lead to non-performance of PID. Hot air oven specifications related to PID settings need to be set well.

Solution: Calibrate & Set internal parameters appropriately: Calibrate the Temperature sensor and indicator and set the values appropriately to get auto-tuned results. Take the manufacturer’s help in adjusting the PID internal settings. Hot air oven temperature and time response time check can be done after calibration.

Sometimes DUT (Device under test) heats the specimen when it is itself under heated conditions. Insufficient space between specimens, excessive temperature settings, radiative capability

Solution: The need for appropriate ventilation is a must. Spacing between the specimens is also a requirement. Using racks can be useful in it. Following the material standard for the performance of curing, dry heating, and sterilizing will be fine so that the desired temperature for the specimen can be provided.

If the insulation is not done appropriately then the heating will not be uniform and it will react with the outer atmosphere. This is an issue that needs to be resolved with proper insulation in the hot air oven.

Solution: The Hot air oven should have mineral wool insulation facilities. Presto hot air oven provides advanced and durable Glasswool insulation with which improper sealing issues can be handled.

Durable and precise hot air oven parts can be searched on Presto Spares.For more information regarding the equipment and as a reliable Hot air oven manufacturer Presto will be pleased to solve queries and technical clarities

Looking for the best Hot Air Oven price? Get a high-performance Hot Air Oven designed for precise drying, sterilization, and heat treatment in laboratories and industries. Ensure efficiency and reliability with our top-quality equipment.

Contact No: +91 9210 903 903

Email: info@prestogroup.com

Get your quote today!

Related Blogs

Master ASTM B117 testing with Presto Group. Avoid costly errors and ensure reliable, accurate salt spray results every time.

Understand why tensile tests give incorrect results and learn best practices to avoid specimen and machine-related failures.

Learn what a Colorimeter is, how it works, and its key parts, uses, and advantages in color measurement. Discover how this precision instrument ensures accurate color consistency across industries.