Gaurav Malhotra-Testing Instrument Expert

06-3-2025

The Bursting Strength Tester Machine is an essential quality control instrument used in industries like packaging, textiles, and paper manufacturing. This device helps evaluate the burst resistance of materials such as corrugated boxes, fabric, and paperboard, ensuring durability under pressure. It is a key tool for maintaining product integrity during storage and transportation.

A Bursting Strength Testing Machine measures how much force a material can withstand before it bursts. It is widely used in quality assurance for packaging to assess the pressure resistance of various materials. Whether testing corrugated box strength or checking the burst resistance of textiles, this equipment plays a crucial role in industrial material testing.

Bursting strength refers to the maximum pressure a material can withstand before rupturing. This property is crucial for ensuring the durability and reliability of packaging materials, textiles, and paper products.

The Bursting Strength Tester Principle is based on applying hydraulic or pneumatic pressure to a sample until it ruptures. The sample is securely placed between circular clamps, and a rubber diaphragm expands to exert force. The applied pressure is recorded at the point where the material bursts, indicating its strength and durability. This test is essential for understanding how materials perform under real-world stress conditions.

The core components of a Bursting Strength Tester helps in better operation and maintenance. The main components include:

Rubber Diaphragm – Expands uniformly to exert controlled pressure on the sample.

Clamping Unit – Ensures the sample remains stable during testing.

Pressure Mechanism – Can be hydraulic or pneumatic, applying consistent force.

Gauge or Digital Display – Measures and displays the applied pressure with high accuracy.

Control Panel – Used to set parameters and control the testing process.

Testing Chamber – Houses the sample and prevents pressure leakage.

Each of these components plays a vital role in delivering precise and repeatable burst strength measurements.

For carton box testing, the Bursting Strength Tester of a Corrugated Box determines the maximum pressure a corrugated or fiberboard carton can withstand before failing. This test ensures that boxes used in shipping and storage can endure rough handling and stacking without breaking. Carton box manufacturers rely on these testers to comply with industry packaging standards and enhance product protection during transit.

A Paper Bursting Strength Tester is specifically designed to assess the burst resistance of paper and paperboard materials. This is crucial for manufacturers to maintain the paper quality standards required in the packaging industry. The Paper BF Testing Machine is commonly used for this purpose, ensuring compliance with industry benchmarks.

A Hydraulic Bursting Strength Tester uses a hydraulic mechanism to apply uniform pressure on the sample until it bursts. This method is particularly effective for high strength material , such as thick cardboard , multi-layered corrugated sheets , industrial textiles.

The material sample is clamped securely.

Hydraulic or pneumatic pressure is applied via a rubber diaphragm.

The pressure gradually increases until the material bursts.

The burst strength value is recorded, indicating its durability and resistance.

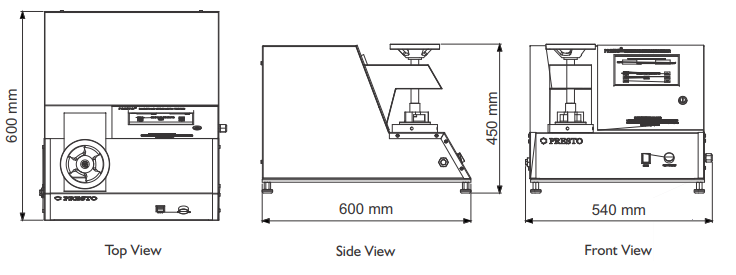

Understanding the Bursting Strength Tester Diagram helps visualize its components and working mechanism.

Key Components:

A well-designed diagram provides insights into the testing setup, working principle, and essential components of the tester, ensuring proper operation and calibration.

The bursting strength unit of measurement is typically expressed in kilopascal ( kPa ), or pounds per square inch (psi). The unit depends on industry standards and material type.

To conduct a bursting strength test, follow these steps:

When selecting a Bursting Strength Tester , consider the following specifications:--

1. Why is bursting strength important in packaging?

It determines how much pressure resistance a material has, ensuring packaging can withstand transport and storage conditions.

2. How often should a Bursting Strength Tester be calibrated ?

Regular calibration every 6-12 months is recommended to maintain accuracy in burst strength measurement.

3. What factors affect the bursting strength of a material?

The thickness, material composition, and fiber quality influence the burst resistance of packaging materials.

A Bursting Strength Tester is a important tool for manufacturers looking to enhance our packaging durability , textile strength, and paperboard quality. Investing in the right burst resistance tester ensures compliance with ISO and ASTM standards while improving overall product safety and reliability. For expert recommendations, explore our product range or contact us today!

Presto Stantest is a trusted name in the testing industry, known for its high-quality Bursting Strength Testers. Heres why you should choose us:-

Looking for a reliable Bursting Strength Tester at the best price? Contact us today at +91 9210 903 903 or email info@prestogroup.com for expert guidance and a quote. Ensure top-quality packaging with our precision testing solutions!

Related Blogs

.png&w=1200&q=75)

A Coefficient of Friction Tester is a device that measures the friction between surfaces. This instrument is used by manufacturers and researchers to check material quality and performance.

.png&w=1200&q=75)

A Universal Testing Machine (UTM) is a versatile and essential tool for evaluating the mechanical properties of materials. It helps industries ensure that their materials meet required strength...

A Melt Flow Index Tester is a device used to measure the flow rate of molten plastic under specific conditions of temperature and pressure.