Gaurav Malhotra

20-9-2024

Welcome to the world of friction - fascinating in every sense! For the manufacturer or quality control person, there is no mystery regarding the part played by friction in the processes. The question, though, remains as to how important it is to measure and control friction. Let us now look closer at why the Co-efficient of friction tester is an instrument indispensable for ensuring top product quality and performance.

What Is a Coefficient of Friction Tester?

Have you, or do you ever, experience a product slipping, sliding, or sticking without apparent reason? It is often the coefficient of friction, one of the most important parameters in many industries. But what is a coefficient of friction tester?

One such scientific tool is the coefficient of friction tester, often abbreviated as COF tester. Such a tool can measure quantitatively the frictional forces between two surfaces. That quantity of friction can then be measured in terms of just how much resistance there is to movement between those surfaces. Why does this matter? Right friction is necessary to ensure that the products perform as expected and meet safety as well as performance standards.

Science Behind Coefficient of Friction

Scientifically curious?

Static Coefficient of Friction: The force which must be overcome for the start of movement between static surfaces.

Kinetic Coefficient of Friction: This friction force occurs in surfaces that are moving relative to each other.

Both have their significance in the applications mentioned above. To put it into words, in comparison to the automobile industry it will be vital in terms of ensuring safe tyres or grip on roads and the dynamic value is necessary to provide machinery with smooth and efficient flow.

Why would you care about a Coefficient of Friction Tester?

Have you ever wondered what could go wrong if your friction calculation is wrong or your friction measurement is off? Since all your assumptions about friction could be wrong, the results will be all wrong too and can cause:

Product Failures: Parts that slide or don't function as they are expected to, because of friction being either too high or too low.

Safety Issues: Components may not be able to grip and hold properly causing accidents.

Efficiencies: Machinery or equipment is not working at its maximum potential, based on frictional settings.

A COF tester minimizes all such risks through the precise measurement of such, so the manufacturer will make a proper decision in using any material as well as in design specifications.

How does a Coefficient of Friction Tester work?

Have you ever wondered how these testers would measure friction with the precision they do?

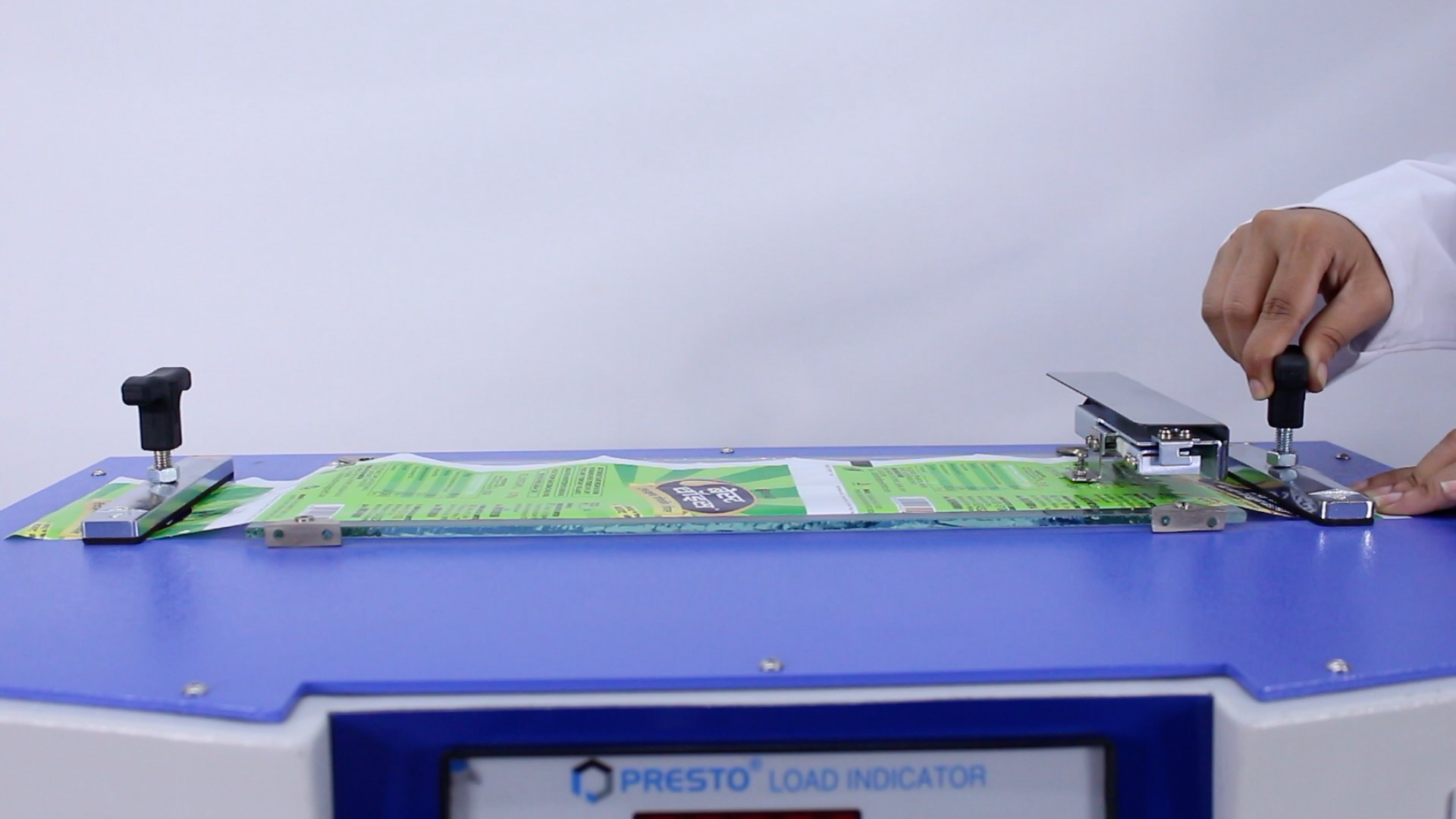

Preparation: The tester usually places a sample material on the surface and exerts a standard force.

Measurement: The tester measures the resisting force created when the sample is under movement or force is applied.

Calculation: Calculate the coefficient of friction by dividing the resisting force by the normal force applied.

The contemporary testers of COF have some advanced features that include but are not limited to, digital displays as well as calculated results for a transparent and reliable outcome.

Types of Coefficient of Friction Testers

Do you know which kind of COF tester suits your needs the best? Here are a few common types:

Manual Testers: These are cost-effective and well-suited for basic measurements, but you operate and calculate the data manually.

Automated Testers: These offer high accuracy and efficiency in such features as automatic load application and data recording.

Specialized Testers: Special tests for special materials or applications. For example, packaging automobiles.

Type would be based on your actual requirement, your budget, and how much accuracy you need to attain.

Coefficient of Friction Tester Price: What Awaits You?

How much do you have to spend on a COF tester? The coefficient of friction tester price can be pretty high and quite varied based on:

Type of Tester: Hand testers are more likely less expensive than automated and specialized ones

Features: Digital readout testers with automatic operation or measurement will be more expensive.

Brand and Quality: You pay more for the name brands that have a good reputation, but they do tend to be more reliable and dependable too.

All in all, you will find a COF tester in the ballpark of several hundred dollars to several thousand dollars. Paying a little extra for a good model is money well spent for precision and durability.

FAQs

What is the difference between static and dynamic COF?

Coefficient of static friction tester is tested using two surfaces under test at rest to each other; its calibration measures the amount of force required to initiate movement. On the other hand, dynamic COF tests surfaces that are already in motion; it therefore creates resistance while in movement.

How often do I need to calibrate my COF tester?

Calibration has to be carried out periodically for accuracy. In general, calibration of a COF tester should be carried out every 6 to 12 months, but this can vary and is more frequent under more intense usage or for special applications.

Can a COF tester measure friction on all materials?

Most COF testers can test on metals, plastics, and rubber. Special testers are needed for the use of special materials or applications.

How do I choose a COF tester that is right for me?

Think about what you're going to measure: whether you need high precision accuracy or something less expensive. It may even be wise to contact a supplier or manufacturer, who can advise you on what type of tester will meet your particular needs.

Where to get a COF tester?

A Coefficient of Friction tester can be obtained from the lab equipment suppliers, manufacturers, or online. Always make sure that you obtain them from the proper supplier so that you are assured of quality products, well-supported, with numerous options for guarantee.

Conclusion

Does your friction control meet the mark? And if you're an automobile maker, a packaging firm, a manufacturing company, or anybody who manufactures something that very much relies on friction, make sure to check and maintain your product's coefficient of friction so you know you will offer the quality and safety of the final product. Invest in a good coefficient of friction tester and stay consistent in avoiding problems and making improvements in the performance of your product to keep on succeeding in your industry.

Well, are you ready to take control of your friction? Leap into the world of COF testers and feel the precision measurements leading to better products and smooth operations. Contact us today and ensure that your questions receive the right guide with just the COF tester.

Related Blogs

Achieve accurate inspection of automotive and aerospace components using optical profile projectors. Improve quality control and precision.

Prevent transit damage with advanced drop testing machines. Improve packaging strength, reduce returns & buy drop tester in India today.

Understand why tensile tests give incorrect results and learn best practices to avoid specimen and machine-related failures.