Gaurav Malhotra-Testing Instrument Expert

28-1-2025

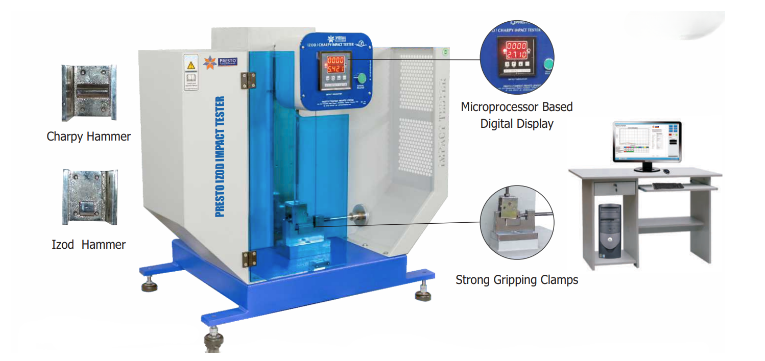

PRESTO IZOD/Charpy Impact Tester proves to be a revolutionary solution that exactly fits in with high demands. This sophisticated equipment is specifically tailored for determining material impact resistance under sudden force or impact with accuracy and functionality unmatched among their peers by industry professionals.

An essential process in impact testing is measuring the material's capacity to withstand force without fracturing upon receiving sudden forces. This ensures products can survive given real-world conditions of stress by helping manufacturers and researchers know exactly the toughness of the material.

Both the Charpy and Izod impact tests measure resistance to impact, but their procedures and configurations are different :

Charpy Impact Test

Izod Impact Test

Recommended for determining the impact strength of plastics and polymers.

These different methodologies fulfil the varied requirements of different industries, and the availability of a testing machine that can work for both would be the ultimate in versatility.

Professionals in the testing and manufacturing industries need equipment that ensures accuracy, ease of use, and compliance with international standards. PRESTO IZOD/Charpy Impact Tester excels in all these areas, providing a comprehensive solution that:

The PRESTO IZOD/Charpy Impact Tester is an all-in-one solution made to meet the international testing standards of ASTM D256-10, ASTM D618-13, ASTM D883-12, ASTM D1204-14, ASTM D1248-12, and ASTM E691-14. The powerful machine is fully equipped with high-end features for guaranteed reliable, accurate, and user-friendly performance.

Microprocessor-Based Display

The microprocessor-driven interface guarantees accurate and consistent test results with no human error and gives precise data every time.

The tester gives instant feedback on the energy absorbed and the angle of the test specimen, giving full information about material behaviour under stress.

Dedicated fixtures for all the test methods are provided for increased convenience and easy working without interference.

Electromagnetic Pendulum Release Mechanism:- This novel mechanism guarantees a less vibratory, well-controlled pendulum motion that reduces inaccuracies during impact.

Graphical Test Reports:- Report generation in a graphical format like Energy vs. Angle allows for easier interpretation and effective communication of results.

Data Sharing and Connectivity:- With a USB port, alphanumeric keypad, and email capability, the machine provides quick data entry, report distribution, and connectivity with PCs for smooth workflow integration.

Inbuilt Calibration Facility:- Accuracy is achieved easily through an inbuilt calibration facility in the tester, thereby ensuring long-term reliability and standards compliance.

Multiple Test Units:- Global applicability and diverse applications are made possible through the facility of calculating the test result in units such as J/m, Kg.cm/cm, and Kg.m/m.

Tough Grippings Jigs:- The tough-grippings jigs ensure high stability in such a way that the specimens never slip during the test, thus not allowing any mistakes or failures.

Industrial Use:- This PRESTO IZOD/Charpy Impact Tester comes in very handy for professionals and experts working in the fields as described below:

Automotive:- Ensuring the safety and robustness of hub caps, bumpers, and dashboards

Aerospace:- Materials' resistance to shock and impact under extreme conditions.

Plastics and Polymers:- The toughness of new formulations and composites.

Construction:- Structural material reliability evaluation to sudden impacts.

The Charpy impact test procedure consists of the following steps:

Preparation of specimen for a particular dimension according to ASTM standards for Charpy impact test specimens.

Placing the specimen horizontally on the testing fixture such that the notch is oriented away from the pendulum.

Release the pendulum using the electromagnetic mechanism and strike the specimen.

Note the amount of absorbed energy and interpret the results in terms of material toughness.

The Charpy impact machine is a vital tool to ensure all these are carried out with accuracy, meaning professionals will gain actionable insights about material properties.

Q1: What are the main applications of the Charpy and Izod impact tests?

A: These tests measure the toughness and impact strength of materials, so manufacturers can be assured that their products are safe and will perform as required.

Q2: What role does an electromagnetic pendulum play in accuracy?

A: The mechanism ensures smooth and controlled motion, eliminating inconsistencies caused by manual release methods.

Q3: What are the standard specimen sizes in Charpy impact tests?

A: Dimensions will depend on the testing standard. However, common dimensions include a length, width, and notch depth that are identical across all samples for consistency.

Q4: What is the graphical report feature helpful to professionals?

A: Graphical reports, such as Energy vs. Angle, provide visual insights into material behaviour, making data analysis more intuitive and effective.

For professionals looking for a reliable and efficient impact testing solution, the PRESTO IZOD/Charpy Impact Tester represents the pinnacle of innovation and performance.

Phone: +91 9210 903 903

Mail: info@prestogroup.com

Related Blogs

Advanced hot air ovens for research labs ensure stability, safety and control. Upgrade your lab—buy reliable ovens in India now.

Learn common UTM testing errors, their causes, and techniques to improve accuracy through calibration, alignment and training.

Cyclic Salt Spray Testing Machine explained with diagram, test cycles, working process, and industrial applications. Learn how cyclic corrosion testing ensures product durability and compliance.