Unlocking the Power of Box Compression Testers: The Key to Increased ROI for Packaging Manufacturers It's all or nothing about packaging material str

Gaurav Malhotra

12-11-2024

It's all or nothing about packaging material strength. The package has to withstand the pressures from stacking, shipping stress, and the perils of the supply chain. So, how does a manufacturer ensure that his package is stout enough? Well, enter the box compression tester, an essential tool for anyone serious about testing the durability of their package. In this blog, we're going to explain why box compression testing is important and how Presto's box compression testers can enhance your laboratory, along with what return on investment businesses can look forward to when they apply this technology in their processes of quality control.

Why is that important?

One of the most crucial quality control checks on the packaging is compression testing a box. What this basically tests is the ability of a box or indeed corrugated cardboard to resist external forces and keep its shape throughout transit, in storage, and while in use. In this sense, it's aimed at showing a real-life model of things that can befall packaging--stacking pressure, impact during transport, and the weight of the products that it is purported to protect.

Packaging that fails a box compression test can lead to damage to the product, dissatisfaction of customers, and returns, and thus is quite an important matter for brands interested in ensuring quality but avoiding potential losses.

Presto's Package Compression Testers are designed according to industrial standards to guarantee accurate, reliable, and consistent testing so manufacturers can meet international packaging standards, including TAPPI T804, ISTA 2A, and ASTM D642.

Presto: Your Box compression tester manufacturers

Choosing your box compression tester manufacturers can offer you a whole range of testing instruments designed to ensure the quality and performance of a product in packaging. Its box compression tester is no exception in providing what customers demand in their labs for testing purposes: reliability, precision, and ease of use.

Why You Should Invest in a Box Compression Tester?

1. Reduce Packaging Failures and Product Damage

A compression tester for boxes can help diagnose packaging design weaknesses before a failure has occurred. The cost of lost goods, returned packages, and unhappy customers can be astronomical. According to the Packaging Digest, the average unit cost of a product return due to packaging failure is around $25, excluding shipping. Compression testing by a compression tester for boxes can save manufacturers as much as 30% in return-related costs by diagnosing packaging flaws early on.

2. Efficient Packaging Design

Genuine compression testing data of a reliable box ensures that manufacturers improve the design of their packaging by using less material for optimum functionality, hence eliminating unnecessary costs. According to the Packaging Innovation Trends 2022, packaging engineers note an improvement of 20% through an efficient design after introducing the presence of compression testing into the workflow, assuring them that the box functions at an optimal level through the minimum use of material required. This, therefore leaves companies saving on the consumption of materials, hence a more sustainable company.

3. Adherence to Industry Standards

The boxes you use for packaging need to pass the set industry standards. You may want to conduct testing such as TAPPI T804 in corrugated containers, ISTA 2A on package testing, and ASTM D642 compression resistance to ensure your product adheres to worldwide standards. This can be your only means of protection from heavy fines, recalls, or costly litigations if you check for compliance through a box compression tester.

4. Reduced Long-Term Costs

As seen, damage to products and return costs are very expensive. The upside of this is that box compression tester reduces such costs by keeping the integrity of packaging, thus fewer damages to products and reduced customer returns. It has been demonstrated that any implementation of box compression testing translates to an overall packaging reduction of 12% through a reduction in packaging waste, minimization of production errors, and enhanced protection of final products.

We have a collection of models for a box compression tester to meet distinct requirements.

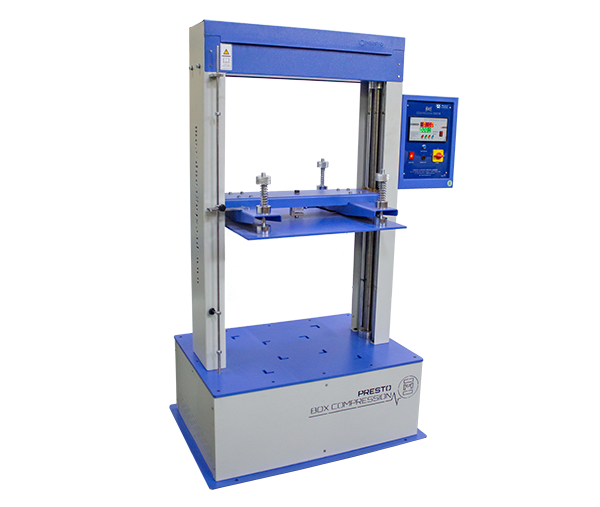

1. Box Compression Tester Digital

Standard:

ASTM D642, ASTM D4169, TAPPI T804, ISO 12048, and JIS Z0212

Technical Specifications:

Type: Compression

Capacity: 500 Kgf

Display: LED (Digital)

Accuracy: ± 2% full scale (with master load).

Least Count: 200 gm

Power: 220V, Single phase, 50 Hz

Test Platform Size: 450 * 450 mm

Test Speed: 12.5 ± 2.5 mm/min

Motor: 1 HP Three Phase, 1350 rpm

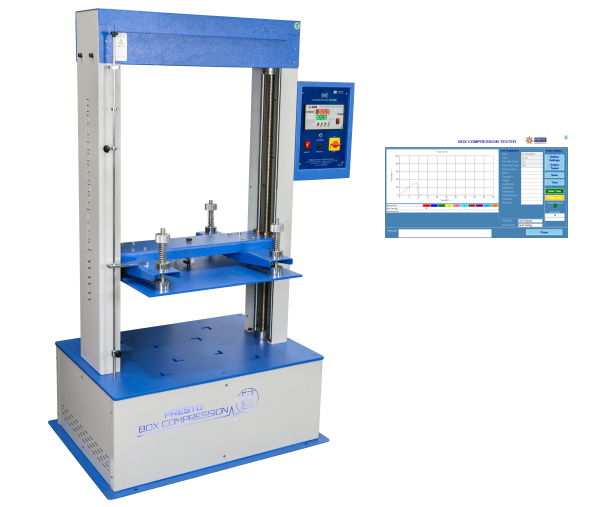

2. Box Compression Tester Computerised

Standard:

ASTM D642, ASTM D4169, TAPPI T804, ISO 12048, and JIS Z0212.

Technical Specifications:

Type: Compression

Capacity: 500 Kgf

Display: LED (Digital)

Graphical

Accuracy: ± 2% full scale (with master load).

Least Count: 200 gm

Power: 220V, Single phase, 50 Hz

Test Platform Size: 450 * 450 mm

Test Speed: 12.5 ± 2.5 mm/min

Motor: 1 HP Three Phase, 1350 rpm

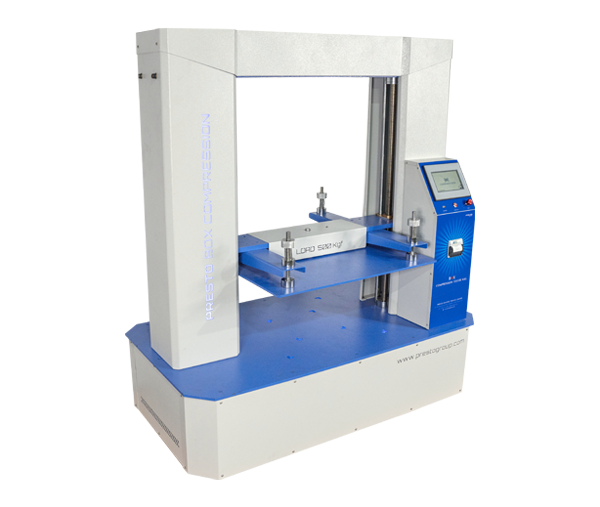

3. Box Compression Tester – NXG Generation Model

Technical Specifications:

Display: 7" TFT LCD colour screen

Accuracy: ± 2% full scale (with master load)

Power: 220V, Single / Three phases, 50 Hz

Test Speed: 12.5 ± 2.5 mm/min

Results / Report: 10 Samples max and average

Displacement Least count: 0.1 mm

Multi-Speed: Programmed Test speed / Home Speed feature

Peak Hold Facility: Yes (Max. Test Results save in Memory)

Safety Switch: Upward & Downward Limit Switches

Material: Mild Steel

Finish: Powder-coated Havel Gray & Blue combination finish and bright chrome/zinc plating for a corrosion-resistant finish

Pre-load function: Can be programmed as user-defined inputs

Trend Graph: Yes (Load vs displacement)

FAQs About Box Compression Testers

1. What is a box compression test?

This test examines the ability of a box to compress. One typical setup for this kind of test is when the box is pressed between two plates until the box either deforms or breaks. It is a crucial test meant to ensure the manufacturing of packaging systems that can withstand stacking, transportation, and storage pressures.

2. Box compression test formula.

The box compression strength can generally be formulated using this formula:

Box Compression Strength = Load (N)/ Area (m²)

The load refers to the force applied to the box, and the area refers to the area of the box surface being tested.

3. What is the compressive strength of a box?

The compressive strength of a box is the maximum pressure that can be gained in it before its deformation or failure. Its value depends on various factors that, to a large extent, include the material that is used for making the whether it is corrugated cardboard or what-have-you, the design of the box, and the test conditions.

A Box Compression Tester for Better Quality Control and ROI

In an increasingly challenging packaging environment, a box compression tester will soon be crucial in preserving package integrity and product protection. Advanced testers from Presto help ensure optimal performance in the packaging while minimizing waste material therefore complying with requirements.

The box compression tester might pay for itself in money saved from returned products, reduced packaging costs, or improved efficiency. Purchasing a box compression tester from Presto will help protect both your bottom line and your brand's reputation.

Want to improve your packaging? Call Presto now for the perfect solution for any box compression tester need.

Phone: +91 9210903903

Mail: info@prestogroup.com

you may also like

- The Ultimate Guide to Universal Testing Machines (UTM)

- Guide to Bursting Strength Tester: Working, Benefits & Price

- Ultimate Guide to Melt Flow Index Tester: Operations, Advantages, and Uses

- A Complete Guide to Box Compression Tester: Methods & Applications

- Hot air oven not working? Common problems & fixing issues

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Get a Quote