Vishal Malhotra-Testing Instrument Expert

29-4-2025

Imagine this: You've honed your product. It's new, great quality, and poised to amaze your customer. It gets shipped out. only to turn up damaged, the box bent like a concertina. Your customer is unhappy, your reputation suffers, and replacement costs rise. What's gone wrong? More often than not, it's the inadequate packaging strength of the corrugated box's edge crush resistance.

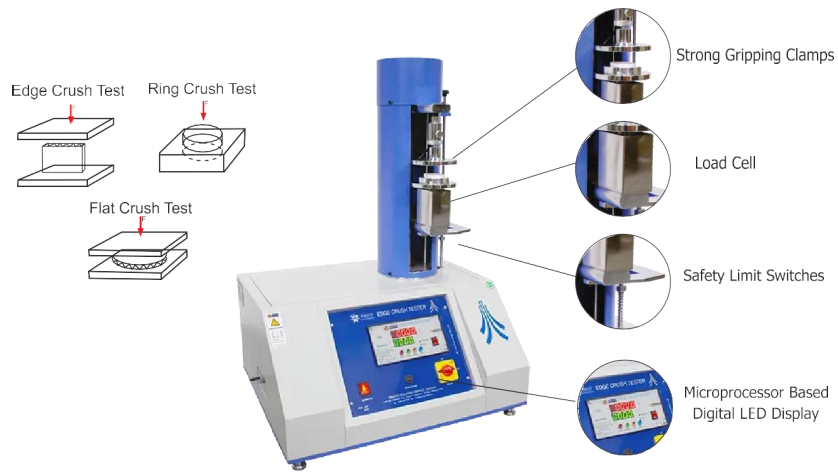

This is where the packaging quality control unsung hero comes in: the Edge Crush Test (ECT), and the critical tool that does it, the Edge Crush Tester. Being aware of and applying this test is crucial for any company depending on corrugated packaging to safeguard items while in transit and storage.

Consider "Global Gadgets Inc.," a fictional electronics company. They faced soaring return rates due to shipping damage. Their sleek gadgets were arriving cracked or dented. Initially, they blamed shippers, but a closer look revealed their corrugated boxes were frequently collapsing under stacking pressure in warehouses and during transit. The problem was clear: their packaging couldn't withstand the rigours of the supply chain.

The answer was to invest in their quality control process. They purchased a digital Edge Crush Tester and set up a rigorous testing regime using the applicable Edge Crush Test standard. By continually testing the edgewise compression strength of their board supply, they could guarantee that it complied with specifications. They also employed an Edge Crush Test Calculator (usually founded on the McKee formula) to more accurately forecast the overall Box Compression Strength (BCT) from their ECT measurement, enabling them to design the box optimally without over-engineering (and over-expenditure). The result? A stunning decrease in damaged products, substantial savings on replacements and returns, and delighted customers. This inexpensive investment in testing converted their packaging from a liability to a trusted asset.

The Edge Crush Test tests the capacity of a small piece of corrugated board to withstand compression forces applied perpendicular to the direction of the flutes, on its edge. Imagine it as testing the 'stacking strength' capability of the board itself. It informs you of the amount of pressure the edges of the board can support before buckling or crushing. This measurement, usually expressed in pounds per inch (lb/in) is an important measure of the finished box's capacity to support weight and withstand damage.

Performing an ECT requires precision and adherence to standards. While specifics might vary slightly based on the standard used, the general Edge Crush Test procedure involves:

Although the raw output of the ECT device is the peak force, the value more traditionally reported as an ECT is Force per unit length (as outlined previously). There is no single "Edge Crush Test formula" in the sense you would imagine a complicated physics formula.

But the actual power is achieved when you utilize the ECT value. That is where Edge Crush Test Calculators prove to be extremely useful. These calculators, generally employing empirical equations such as the McKee formula, enable prediction of the theoretical Box Compression Strength (BCT) – the highest stacking load a finished box can support – from the ECT value, board calliper (thickness), and box dimensions.

Some trusted Edge Crush Tester manufacturers specialize in testing equipment for materials. Testing Machines Inc. (TMI), Thwing-Albert Instrument Company, IDM Instruments, Presto Stantest, and others across the world are some popular names. The following factors affect Edge Crush Tester price when considering it:

1. Brand reputation and build quality.

2. Load capacity and accuracy specifications.

3. Digital features, automation, and software integration.

4. Calibration and service packages.

Prices can range from a few thousand dollars for basic models to significantly more for highly automated, high-precision systems. It's essential to balance budget with the required features and accuracy for your specific application. Investing in a reliable corrugated edge compression tester is investing in consistent product quality and reduced operational losses.

Edge Crush Test is more than a mere technical test; it's the foundation of great packaging design and quality control. By learning how to conduct Edge Crush Test tests, using precision ECT machinery, and working with tools such as an Edge Crush Test Calculator, you can guarantee your corrugated packages deliver the superior protection your product needs. Don't take the safety of your product on chance – equip your quality control with the power of the Edge Crush Test.

Prepared to reinforce your packaging? Discover our selection of high-accuracy Edge Crush Testers or speak with our experts today to schedule an appointment to discover the ideal ECT instrument for your application! Share this article if it was useful!

Q1. What standards are used for Edge Crush Testing?

Ans. A number of international and industry standards regulate the Edge Crush Test to achieve consistency and comparability of results. The most prevalent are:

It is important to determine which standard your industry or customers demand and ensure your Edge Crush Tester and procedure meet it.

Q2. Is the Edge Crush Tester appropriate for quality control during production?

Ans. Yes, absolutely. The Edge Crush Tester is an essential tool for quality control in box converting plants and corrugated board manufacturing. It enables manufacturers to:

Q3. What is the difference between Edge Crush Test (ECT) and Ring Crush Test (RCT)?

Ans. Both RCT and ECT test the compression strength of paperboard components but are different in what they actually test and how:

Although associated (stronger layers typically translate into greater ECT), ECT is held to be more directly indicative of ultimate box performance.

Q4. What are the advantages of a digital Edge Crush Tester?

Ans. Digital Edge Crush Testers have many benefits over older analogue models:

Q5. What does ECT bear to box compression strength?

Ans. ECT is an initial predictor of Box Compression Strength (BCT). BCT tests the peak load that a completed box will support before top-to-bottom compression collapse (simulating stackings). Though BCT is the final indicator of stacking capability, it's a destructive test run on an entire box. ECT, conducted on a sample board of small size, indicates strongly toward this possible strength. The relationship is often estimated using the McKee formula, which incorporates the ECT value, the board calliper (thickness), and the box perimeter. A higher ECT value generally leads to a higher BCT, assuming other factors (box design, dimensions, flute type) are constant. Therefore, controlling ECT is critical for achieving desired BCT performance.

Get in touch with our experts today to know the most competitive Edge Crush Tester Price in the industry.

Call Now: +91 9210 903 903

Email Us: info@prestogroup.com

Don't miss out on quality and affordability—request a quote now!

Related Blogs

Tensile strength testing is vital for ensuring material quality and reliability. Find out how this essential test impacts product performance and safety.

Test the bond strength of your materials with a peel strength tester. Perfect for quality assurance in packaging and manufacturing industries. Explore models and specifications now.

The Vacuum Leak Tester serves as a quality control instrument which uses vacuum pressure to detect package leaks on test specimens.