Gaurav Malhotra-Testing Instrument Expert

01-3-2025

A Box Compression Tester is a crucial tool for evaluating the compression strength of packaging materials. It helps manufacturers determine the durability of corrugated boxes and shipping containers, ensuring they can withstand stacking pressure during transit and storage. This guide covers its working principle, uses, and importance in packaging quality control.

A Box Compression Tester is a laboratory testing machine designed to measure the compressive strength of packaging boxes, including corrugated cartons and other materials used for shipping and storage. By using this machine, manufacturers can assess how much weight a container can endure before collapsing, ensuring that packaging remains reliable throughout its supply chain journey. The box compression test plays a critical role in quality control, helping businesses avoid damage-related losses

A Box Compression Tester has important parts that help check the strength of packaging materials. It has an upper plate that moves down to press the box and a lower plate that stays still to hold it in place. A sensor measures the pressure applied until the box bends or breaks. A digital screen shows the force in real-time, making it easy to get accurate results.

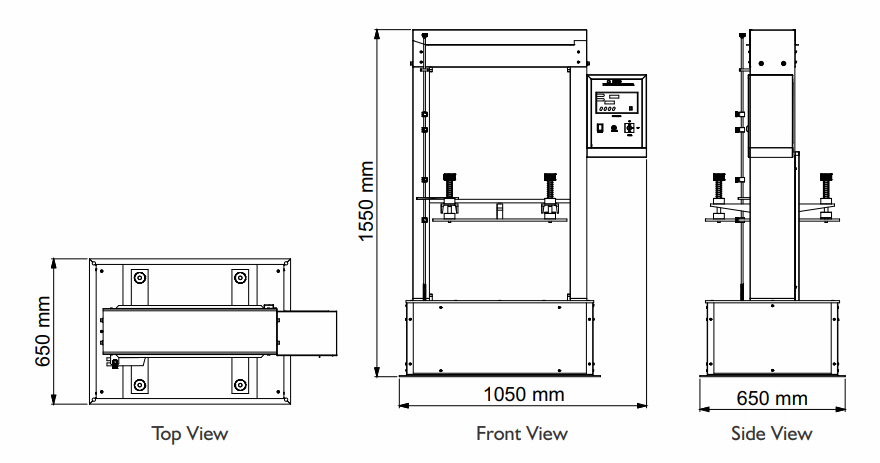

The following diagram illustrates the fundamental components of a box compression tester :-

The upper plate moves downward at a controlled rate, simulating real-world stacking conditions. The load sensor measures the resistance of the box, helping determine its stacking strength and load-bearing capacity. This setup ensures accurate force application and provides critical data for packaging durability assessments. Industries such as e-commerce, pharmaceuticals, and food packaging benefit from these tests by optimizing material selection and reducing damage-related losses.

The box compression tester operates on the principle of applying a gradually increasing compressive force on a packaging box until it deforms or collapses. The machine consists of two compression plates, where the bottom plate remains fixed, and the upper plate moves downward at a controlled speed. As the force increases, sensors measure the resistance of the box, providing real-time data on its load-bearing capacity. The results help manufacturers determine the box’s stacking strength and optimize materials accordingly.

The BCT test (Box Compression Test) follows standardized procedures to ensure consistent and accurate results. This test is crucial in determining the compression strength tester capabilities and verifying the durability of packaging materials under different load conditions.

The box compression tester is widely used across various industries to ensure packaging integrity. Some common applications include:

A carton compression tester plays a crucial role in maintaining packaging quality control. It verifies that corrugated packaging can withstand stacking and transport conditions, reducing the risk of product damage during handling. The box compression test method follows industry standards to ensure accuracy in packaging evaluations.

Many businesses rely on carton performance testing to prevent packaging failures that could lead to financial losses. A weak box may collapse under weight, but with proper box stacking strength tests, manufacturers can optimize packaging for warehouse storage safety.

To ensure global acceptance, box strength testers comply with major industry regulations, including:

1. What is a box compression test?

A box compression test is a method used to determine the maximum compressive force a packaging box can withstand before deforming or collapsing. It helps assess the strength and durability of shipping cartons and other packaging materials.

2. What is a compression tester for?

A compression tester is used to measure the compressive strength of packaging materials, ensuring they can handle the load and stacking pressure during storage and transportation. It is essential for maintaining packaging quality and preventing product damage.

3. What is the unit of BCT?

The unit of Box Compression Test (BCT) is typically measured in kilograms-force (kgf), Newtons (N), or pounds-force (lbf), depending on the testing standard and region.

4. What is the formula for the box compression test?

The formula for box compression strength (BCT) is:

BCT = Load at Failure (N) / Box Area (m²)

This calculation helps determine the maximum load a box can withstand before collapsing, aiding in the optimization of packaging materials.

5. Why Choose Presto Stantest Pvt Ltd?

Presto Stantest Pvt Ltd is a leading provider of high-quality box compression testers and other packaging testing equipment. With decades of experience in the industry, we are committed to offering precision-engineered solutions that help businesses enhance their packaging durability and compliance with international standards. Our products are known for their accuracy, durability, and advanced technology, ensuring reliable testing results. Whether you're in manufacturing, logistics, or retail, Presto’s cutting-edge compression strength testers provide unmatched performance and reliability. Trust us for your packaging quality needs and experience industry-leading expertise.

Need a reliable box compression tester at the best price? We’ve got you covered! Our experts will help you find the right machine for your packaging quality checks. Call us at +91 9210 903 903 , email info@prestogroup.com to get the best deals today!

Investing in a box compression tester is essential for businesses aiming to improve packaging quality, reduce damage rates, and ensure compliance with industry standards. By integrating box strength testing into their quality control processes, manufacturers can enhance packaging reliability and optimize costs. Whether for e-commerce, logistics, or industrial packaging, a box compression tester is a critical tool for maintaining product integrity throughout the supply chain.

Related Blogs

Test the bond strength of your materials with a peel strength tester. Perfect for quality assurance in packaging and manufacturing industries. Explore models and specifications now.

The Vacuum Leak Tester serves as a quality control instrument which uses vacuum pressure to detect package leaks on test specimens.

Explore how a humidity chamber operates with insights into its working principle, detailed diagram, and practical applications across industries like packaging, electronics, and pharmaceuticals.