.png&w=1920&q=75)

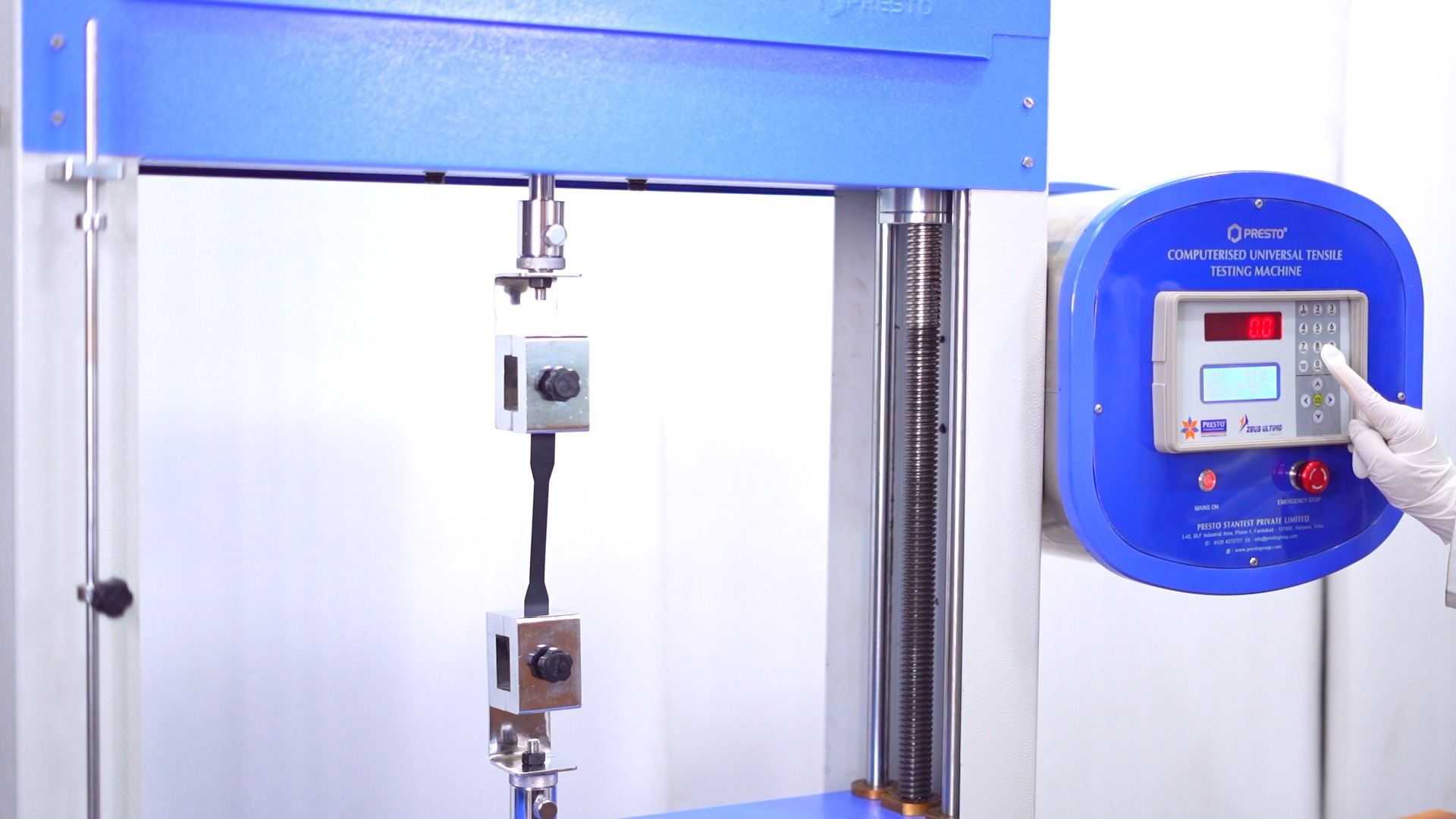

Material testing demands accuracy. Engineers, researchers, and manufacturers rely on equipment that, besides meeting expectations, must deliver far more than that: materials integrity and structure integrity. Such efforts form the foundation of these tests Universal Testing Machine is at the core of testing performed in mechanical testing labs for any industry. Whether it is the tensile strength of materials, compression tests, or bending behavior, the UTM machine is essential and cannot be substituted in material property evaluation.

In this blog, we will discuss the critical role of crosshead speed in Universal Testing Machines, universal testing machine cost, etc. We will explore its impact on the accuracy of material testing, how it influences testing outcomes, and why it is an essential parameter to control for obtaining precise and reliable results. Additionally, we’ll cover the overall specifications of the best Universal Testing Machine, price considerations for UTM testing machines, best practices for operation, and essential maintenance tips to keep the equipment in peak condition.

Presto, being a leading UTM machine manufacturer, has always developed testing machines that are of high quality, reliable, and easy to use. Our UTM systems have precise engineering with various needs in the industries. Presto focuses on delivering robust solutions to customers by providing them with unmatched technical support and service.

For Universal Testing Machines, crosshead speed is of great importance in affecting the correctness and consistency of test data. A crosshead forms part of the UTM that supports the test material within it during the testing period. In tensile tests, it pulls or stretches while in compression tests, it compresses.

It is normally given in mm/min, although it may vary based on whether or not the test is qualitative and the type of material involved. Controlling the crosshead speed is very vital since it directly influences the strain rate, and variations might influence the performance of the material and the test.

For example, for high-speed dynamic testing, metals or polymers would react differently compared to when a slow-speed static testing approach is applied. The faster crosshead velocity may create some thermal influence that has altered the material response in its mechanical aspect. At slow velocities, factors such as tensile strength, elasticity modulus, and yield strength could be rated as adequate for evaluation purposes.

Hence, the correct selection of crosshead speed ensures the outcome is valid and uniform. It mimics the natural world where materials are exposed to strain rates due to the specific applications that are either in process, structural loads, or environmental.

The Best Universal Testing Machines always offer many sophisticated features that are in order to deliver precision, reliability, and versatility.

To operate a UTM machine properly and make its long life possible, the operators have to follow specific best practices.

Utilize the Right Test Fixtures: Use the proper fixtures and grips for your testing material. This will not damage the machine and allows for precision.

Obey Manufacturer Instructions: Safety and proper usage depend on technical specifications and operational instructions by the manufacturer.

Maintain the Testing Environment: The testing environment should be free from high vibrations, extreme temperatures, and moisture, which will all adversely affect the test results.

Schedule Maintenance: Check mechanical parts such as crosshead, grips, and load cells to avoid wear and tear.

Do not Overload the Machine: Never overload the UTM machine beyond the rated load capacity. Overloading will damage the machine parts and produce unreliable results.

Avoid Jerky Movements: Jerky movement of the crosshead causes distortion in test data and at times damages the specimen under test.

Do Not Overlook Calibration: The measurement obtained should remain accurate by maintaining regular calibration.

Avoid Usage of Damaged Components: Faulty grip or fixture components may produce inaccurate results and result in machine damage.

Regular maintenance is the most crucial thing regarding the UTM machine because it is the only way to get optimal performance and lifespan. Here are some major maintenance tips:

What is a UTM machine?

It is used to test the tensile and compression strength of the material; basically applies a controlled force on the test piece and measures deformation due to an applied force.

What is the principle of UTM?

A UTM applies a known force to a material and measures its response in terms of the deformation produced by the applied stress. This helps determine material mechanical properties such as strength, stiffness, and ductility.

What are the types of Tensile Machines?

Electromechanical UTM: Suitable for static testing where high precision is required.

Hydraulic UTM: It is used for higher loads as well as dynamic testing applications.

The UTM Machine is an important device to be used in the testing of materials where engineers and researchers obtain primary data about the soundness of materials as well as final products. The crosshead speed is critical in producing accurate, dependable results. It is hence essential to know how this parameter should be set as well as managed to optimally perform.

Contact us for more information like UTM testing machine price, Technical Specifications etc.

Phone: +91 9210 903 903

Mail: info@prestogroup.com

Connect with us for your business enquiries. Generally, we respond within one or two working days.