Presto's Precision: Unveiling Hidden Leaks with Advanced Vacuum Testing

Gaurav Malhotra

25-06-2024

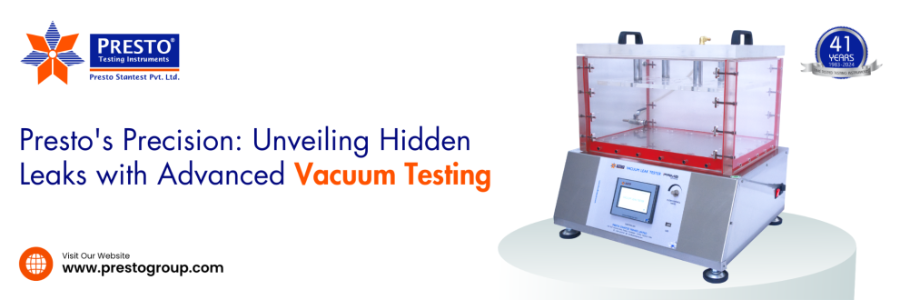

The Vacuum leak tester is a high-quality packaging seal integrity that adds quality control measures. This specialized equipment is crucial for determining seal integrity and finding leaks in a number of industries.

One essential technique for finding leaks and seal flaws without endangering the product is vacuum leak testing. It entails setting up a vacuum atmosphere and putting the product inside a sealed chamber.

Presto Stantest's Vacuum Leakage Tester incorporates essential components designed for precise and reliable testing. The chamber provides a controlled environment where the product under evaluation is securely placed. This setup allows for consistent testing conditions. The vacuum pump is built into the machine for generating and maintaining the level of negative pressure within the chamber without which the optimal results cannot be seen. It ensures accurate testing parameters throughout the process.

A pressure measurement device monitors pressure fluctuations inside the chamber with high sensitivity, detecting even minor variations that could indicate leaks or seal defects. Operators manage the testing parameters through an intuitive control panel, where they set vacuum levels and oversee the testing process to ensure reliable results.

Presto Stantest's Vacuum Testing machine involves systematic procedures to thoroughly evaluate product seals. First, the product sample is prepared according to specific testing requirements, ensuring it is clean and correctly positioned within the chamber. Once sealed, the vacuum system creates a negative pressure environment around the product. Operators then monitor pressure changes using the pressure measurement device to identify any deviations that may signal leaks or compromised seal integrity.

The Presto Stantest Vacuum Leak Tester will help ensure that your packaged product is sealed to your specifications. The benefits of this will be realized by many industries from package manufacturers and converters to end-user packagers in the packaging of Coffee, foiled cups, gels, pouches, cereal, bakery, namkeen, chips, confectionery, snacks, pasta, frozen food, cheese, pet food and treats, medical and pharmaceutical.

Presto's vacuum leak tester consists of several features. Primarily, it consists of a Bubble Emission Leak Test Procedure and a dry chamber specifically for Flexible Package Testing. The specifications of this instrument are adjustable up to 900mb (675mm-Hg).

It consists of a touchscreen display in the case of Presto’s Prima series and a digital display in the case of the digital model. It consists of a two-stage vacuum and holding time setting to ensure maximum efficiency and accuracy.

The capacity of the chamber is 150mm and can be increased to 300mm, as per requirement.

To enter the league of Quality Book the All New Vacuum Leak tester- Prima series NOW!

To get access to new offers and schemes click now and become aware of the current vacuum leak tester price. For further queries please contact us at +91 9210903903, or mail us at info@prestogroup.com.

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free CopyNeed more information

Connect with us for your business enquiries. Generally we respond within one or two working days.

send enquiriesContact Us

Get a Quote