Tensile Testing is one of the primary quality assurance tests in any manufacturing line, tensile strength testing provides critical insights into the mechanical properties of materials. The American Society for Testing and Materials is widely recognized as a leading standard evaluating tensile properties in vulcanized rubber, thermoplastic elastomers, and similar materials. In this blog, we'll be delving deeper into the ASTM D412, sample specifications, testing procedures, and best practices to ensure accurate results.

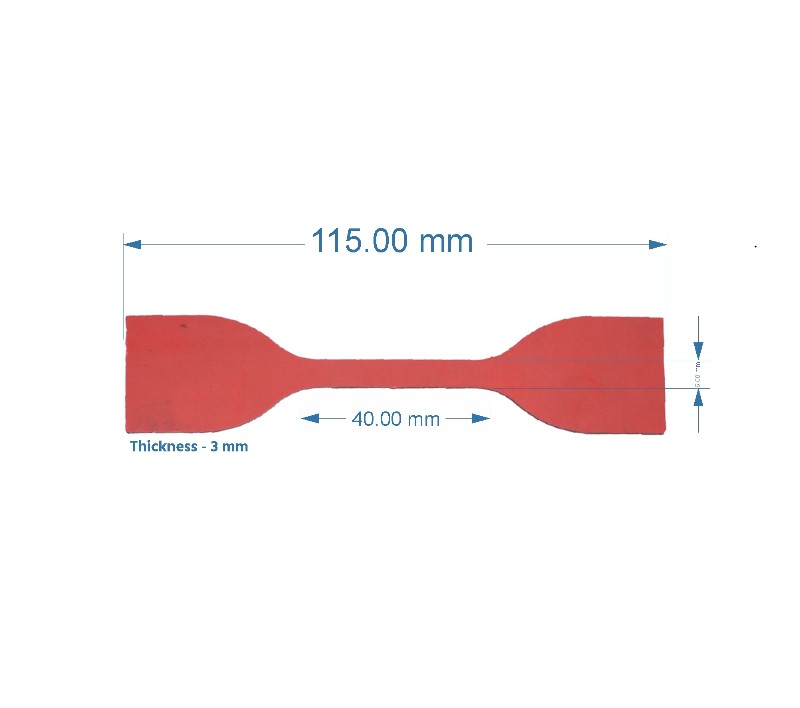

ASTM D412 calls for a dumbbell-shaped specimen and defines a sample that is dimensionally precise concerning thickness and gauge length to achieve uniformity and reproducibility of the test:

Gauge Length 115 mm

It is that part of the sample where elongation is measured. The dimension is measured to ensure that testing results are not different from each other, therefore, no variation across samples is retained.

Thickness: 3 mm

The tensile strength values are considerably affected by sample thickness. To standardize dimensions, uniform tension in stress distributions will be acquired in testing

Width (6 mm)

Width as well as its thickness determines cross-sectional area when considering a sample during the calculation of its tensile strength.

Cross-sections have importance during calculation so such dimensions in this regard is of significant utility while obtaining repeated tensile strength measures.

Selection of Grippers

The choice of grippers is crucial to the success of the ASTM D412 test. Samples may vary in material and shape, so grippers must be adapted to the sample to prevent slippage or uneven force application. For rubber materials, roller-type grippers are recommended as they distribute the clamping force evenly, minimizing the risk of sample deformation or premature failure.

Testing speed, and the state of the test specimen, play an important role in ASTM D412. Testing speed is associated with the elongation rate and response of the material to tensile force. However, unless specified otherwise, it is generally suggested to be tested at a speed of 500 mm/min.

Another crucial aspect is ensuring that the sample breaks in the middle of the gauge length. If the break occurs outside this area, it indicates an improperly conducted test. Such occurrences can be caused by uneven clamping or sample imperfections, leading to inaccurate results and necessitating a retest.

Tensile strength values need proper testing procedures to have reliable values. Here are a few main guidelines for correct measurement:

Inspecting Gripper: The selected grippers for sample material are accurate and good condition is used. In this context, a rubber sample makes it ideal as less slippage occurs if rollers are made.

Calibrating Load: A tensile strength tester has been accurately calibrated. Results may also skew up if loads were not loaded accordingly.

Speed Adjustment: Use the ASTM D412 standard to test speed. Different speeds will change the tensile properties of the material, which will lead to inconsistent data.

Sample Preparation: Samples must be free from defects, uniform in dimensions, and meet the ASTM D412 specifications. Poor sample preparation may lead to premature failure and invalid test results.

Sample preparation and testing under ASTM D412 require the following strict guidelines:

Sample Cutting: Cut dumbbell-shaped samples using a die cutter. The edges should be smooth to prevent stress concentrations.

Testing: Secure the specimen using roller-type grippers. Apply tensile force at a specified speed and elongation along with load at the break to measure the tensile strength.

Analysis: Check whether the sample broke in the middle portion of the gauge length or not. In case not then this test result shall be ignored, and a fresh sample shall be prepared.

Q. Why do tensile strength tests matter for manufacturing?

A. Tensile strength testing ensures that materials exhibit the needed performance, and manufacturers can manufacture highly reliable products.

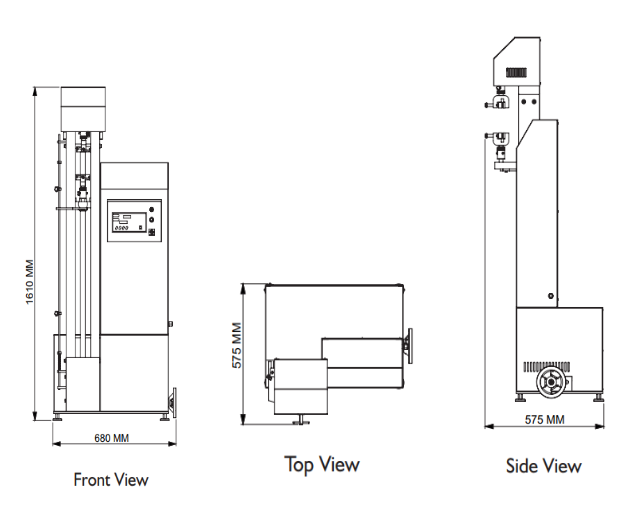

Q. How do I operate a tensile strength equipment?

A. Get to know the user manual of the machine, set up the sample according to ASTM D412, and ensure that it is correctly calibrated. Then proceed to follow the defined methods for conducting these tests.

Q. Are tensile testers available with automated reporting features?

A. Yes, modern tensile testers often include software for automated data collection, analysis, and reporting, enhancing efficiency and reducing human error.

Mastering the ASTMD412 tensile strength of rubber and other elastomers gives manufacturers the foundation they need as they work along with the most critical material component. You need to adhere strictly to the same dimensions, gripper selection, or testing procedure among other factors during the testing and evaluation of quality. You evaluate new materials using this tensile test equipment when you are keen on quality or wish to be assured you meet all regulations on quality standards.

Looking for the Best Tensile Strength Tester at an Affordable Price?

Contact us today for expert advice and unbeatable tensile strength tester prices!

Don’t miss out on ensuring the quality and durability of your products—reach out now!

Connect with us for your business enquiries. Generally, we respond within one or two working days.