.png)

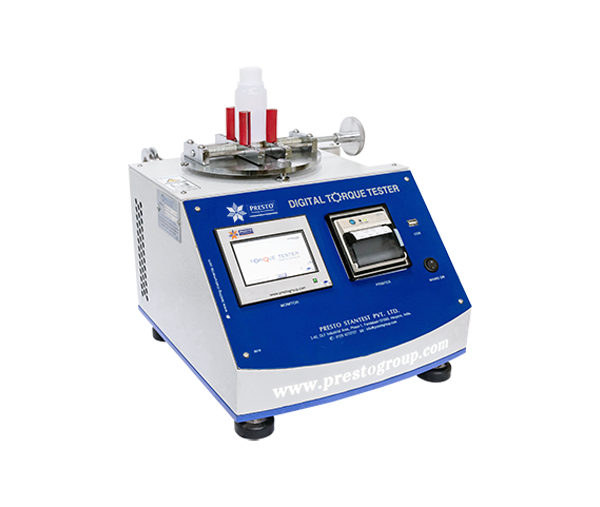

A very simple, yet crucial component in ensuring safety, reliability, and performance is the torque tester. While sealing your favourite soda bottle, ensuring that the car's brake components are fastened securely, or testing a variety of medical devices, torques are an essential part of every application. All these testers are of various categories, which include automatic torque testers, digital torque testers, and bottle torque testers, that can find the proper amount of torque to maintain the quality of the product.

Some products and mechanical systems require proper torque. The low amount of torque results in relatively loose parts, which have low stability. Such a system may be hazardous to safety or break the component down. Too much torque can strip the thread, destroy parts, or cause failure in the material. Torque measurement ensures that components utilize their functions optimized for safety and reliability.

Technical Specification:

Specimen Holding:

Technical Specification:

Maximum Torque Range:

Accuracy:

Least Count / Resolution:

Power Supply:

Display:

Torque Units:

Specimen Holding Capacity:

Maximum Test Bottle Size:

Sample Size Requirements:

Anti-Vibration Pad:

Safety Features:

Technical Specification:

Advanced Security & Connectivity:

Intelligent Test Operation:

Data Management & Storage:

User-Friendly Interface:

Motorized and Repeatable Testing:

Calibration & Quality Assurance:

Technical Specifications:

Torque testers are important in most industries and fields to ensure that final products are safe, durable, and of excellent quality. Let's discuss a few common application scenarios where torque testers play a vital role.

1. Bottle Packaging Industry

Among other applications, one of the most popular applications of torque testers is in the bottle packaging industry.

hey use bottle torque testers and automatic torque testers, ensuring the bottles are well secured. It could be soda bottles, pharmaceutical products, and cosmetics. When the cap is sloppy, the contamination of the product could spill over; if it is over-torqued, the customer may fail to open it. This aspect attracts user experience and product functionality. The manufacturers can easily determine the force applied to the cap by using a bottle torque tester as it must fall within the needed torque range. This would not only be vital for ensuring quality but also fits the necessary torque standards of the industry.

2. Automotive Industry

In the automotive industry, torque testers are considered key devices with critical assembly points such as brake parts, engine bolts, and other suspension fasteners. The failure to tighten these components may cause mechanical malfunctions and pose safety risks, which could even lead to accidents. In the absence of precise torque specifications achieved through digital torque testers, car manufacturers can lay out expensive repairs and recalls.

For instance, when assembling a car engine, bolts on the cylinder head would have to be tightened to an extremely specified torque so that it is not deformed or leaking. Torque testers ensure such critical fastenings are performed correctly.

3. Aerospace Industry

In the aerospace industry, the possibility of precision becomes a major issue, and torque testing is a powerful tool used to check if fasteners, bolts, and structural components are in proper condition. Deviation in such a small measurement may be disastrous in a high-stakes environment of aircraft assembly or maintenance. Typically, they utilize high-accuracy digital torque testers with data logging capabilities, which means the tightening process is documented, and an audit trail is created for compliance and safety regulations.

4. Electronics and Medical Device Manufacturing

In electronics and medical instrument manufacturing, torque testing is used to ensure that screws, fasteners, and other components are tightened within tolerances that will prevent failures during operation. For example, a screw applied onto the circuit board needs to have a uniform torque so that those sensitive components are not damaged. Proper torque in a medical instrument such as a pacemaker or surgical instrument may ensure that a patient's safety is maintained by preventing component failure.

5. Heavy Machinery

Torque testers are also found to be used in determining if fasteners on heavy equipment, cranes, bulldozers, and excavators, have been tightened to the right amount of torque. Sometimes this can cause structural failure, breakdown, or unsafe machinery due to misapplied torque in critical machinery. Torque testers enable technicians to obtain the torque required by machines to run correctly and safely.

Formulae to Calculate torque:

Torque (T) = Force (F) \ Distance(d)\sin(θ)

Where:

T = Torque in Newton-meters or N·m

F = Force applied in Newtons.

d= Distance from the pivot point measured in meters

θ = Angle between the force vector and the lever arm in degrees

How do you test for torque?

Torque testing means the application of force to a rotating object like a screw or bolt to determine the amount of resistance or rotation that occurs. The torque tester will keep track of the amount of force it takes to turn the object to confirm if the amount indeed falls within the specified torque levels.

How accurate is the torque tester?

A good quality torque tester can typically offer an accuracy of ±0.5% to ±1%, based on the model and calibration.

What is a bottle cap torque tester good for?

A bottle cap torque tester is mainly designed to determine the tightening of the bottle caps so as not to be either too loose, with the possibility of leakage, or too tight to open; hence, it will ensure the safety of the products and satisfy the consumers.

Accurate torque measurement has taken the form of securing vital automobile components and medical devices from bottle caps being tightened. Today, it remains to be the integrity and reliability of everyday products. Knowing the specifications, maintenance needs, and applications of torque testers will lead to better quality control and optimal production processes since manufacturers seek to satisfy stringent safety standards. Whether you need a digital torque tester for accurate measurements or an automatic torque tester for high-volume testing, a solution is available to suit the specific needs of the user.

Phone: +91 9210 903 903

Mail: info@prestogroup.com

Connect with us for your business enquiries. Generally, we respond within one or two working days.