Delivery safety of products represents a primary responsibility that packaging engineers need to fulfill jointly with producers. Any product failure from transport drops will result in money losses for both manufacturers and dissatisfied customers who need to return their purchases. An important piece of equipment for such cases is a package drop test machine.

Free-fall duplicating equipment evaluates protective capabilities together with material structural stability through testing of packaging containers, incorporating boxes or cartons. The article describes the approach to selecting drop testers for boxes while examining testing equipment specifications, together with drop tester mechanisms used for carton and box evaluations.

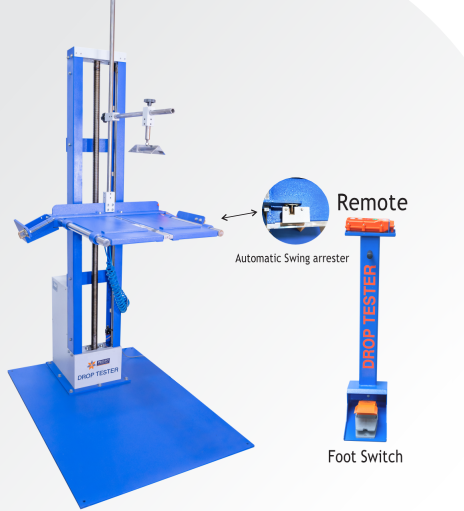

The Package Drop Test Machine exists as a key laboratory instrument used to evaluate packaging box impact resistance through simulated free-fall testing. Package drop test machines operate as laboratory testing tools which determine packaging box impact resistance through sudden drops. Through package drop tester tests, manufacturers discover the most vulnerable areas of their packaging to decide if their shipping and handling conditions will be sustainable.

The test methodology, known as drop testing functions with three different targets, including corrugated cartons and shipping boxes and export packaging units.

The tests use standards established by ASTM D5276 and ISTA, and ISO 2248 to achieve international market acceptance.

Explore Drop Testing Equipment

Before acquiring a drop test machine, users must first establish which type matches their packaging requirements. Let’s break it down:

1. Box Drop Tester

The specific purpose of a box drop tester is to examine medium to large-sized shipping containers which serve logistics operations. The device enables adjustable free-fall drops for testing in combination with simulations of edge and corner impacts as well as flat drops to replicate actual delivery conditions.

Key Features:

2. Carton Drop Tester

A carton drop tester serves the purpose of testing packaging cartons weighing between low and medium weights. FMCG and e-commerce as well as pharmaceutical industries, employ this equipment to ensure the protective packaging needs of the products.

Key Features:

Laboratory testers for box and carton impact testing can be viewed at this link.

Understanding the operating process of drop testers for boxes and cartons leads to proper usage while maintaining test consistency.

Drop Testing Procedure:

The acquisition of a drop test machine becomes essential due to several crucial reasons involving modern competitive packaging and logistics scenarios.

1. Ensure Product Safety

The machine duplicates genuine shipping circumstances to maintain product security within packaging.

2. Improve Packaging Design

Companies should detect failing areas, which lead to identifying better materials for enhanced packaging performance.

3. Comply with Global Standards

The system fulfills the requirements for international packaging standards related to shipping quality.

4. Reduce Cost of Returns

Broken goods and delivery returns can be prevented when packaging fulfills its intended purpose.

The Box Compression Tester provides all the necessary features available on the market at this time.

These are the most crucial features to think about when acquiring a drop tester:

Proper selection of appropriate features yields long-lasting reliability together with accurate test results.

A drop test assessment for your packaging requires analysis through this quiz.

Q1. Whether you check the packaging functionality across variable heights and angles?

Yes / No

Q2. Is Your shipping operations result in product damage at an unpredictable rate?

Yes / No

Q3: Are your drop tests compliant with ASTM/ISTA standards?

Yes / No

Upgrading your testing equipment becomes necessary when your responses to any questions are negative.

Contact Presto for a Free Consultation

The drop testing equipment finds applications within manufacturing sectors, which include:

The machines enable both brand image protection and lower rates of customer complaints through their emphasis on unharmed package delivery.

Every manufacturer and brand which prioritizes product integrity during shipment needs a package drop test machine as their essential equipment. You will achieve dependable and repeatable measurements in testing by selecting the appropriate machine between a carton drop tester and a heavy-duty box drop tester.

Q1. What is the importance of drop testing in packaging evaluation emerges from specific reasons?

Packaging durability assessment requires drop testing because it reveals how products handle movement from handling through shipping until storage completion. The testing method enables manufacturers to discover design weaknesses in packaging and achieve better product protection as well as delighted customers. A drop test machine provides better packaging quality outcomes as well as quality standard compliance.

Q2.What types of products can be tested using a drop tester?

A drop tester serves manufacturers by evaluating electronic merchandise as well as consumer goods and pharmaceuticals and FMCG products and industrial components and fragile items packaged in boxes and cartons. The testing device works best for all types of corrugated boxes in addition to shipping cartons and export packages.

Q3. .What are the standard heights for performing drop tests?

The test standard along with product weight determines the required drop height (ASTM D5276, ISTA, ISO 2248). Conversion between different testing standards requires heights between 300 millimeters and 1800 millimeters. The majority of box drop testers can be adjusted through multiple height settings for packages of different types and test protocols.

Q4. The carton drop tester utilizes what principle for its operations?

The carton drop tester delivers drop scenarios which mimic free-fall operations at specified elevation levels. The tester positions the carton at the designated height then drops it in strict positioning configurations which consist of flat, edge or corner conditions. The testing method evaluates both carton resistance to impacts as well as the protective status of its packaged content.

Ensure your packaging meets industry standards with a high-quality drop tester. Get the most accurate drop tester price and expert consultation tailored to your testing needs!

Call us now: +91 9210 903 903

Email: info@prestogroup.com

Our team is ready to assist you with detailed pricing, product guidance, and custom solutions. Reach out today to find the perfect drop tester at the best price in the market!

Connect with us for your business enquiries. Generally, we respond within one or two working days.