Our Valued Clients

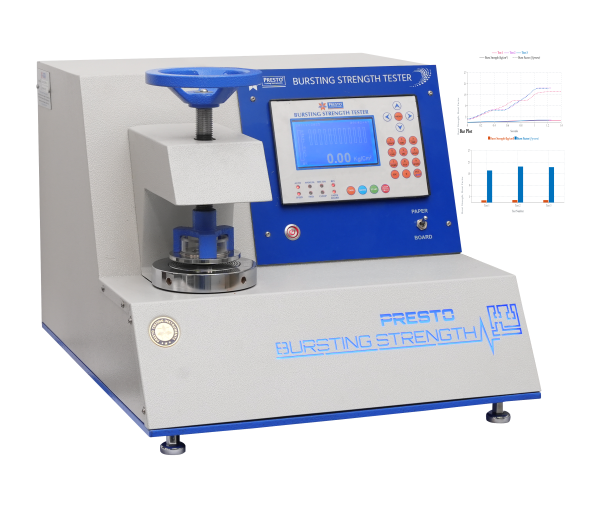

The force required for bursting or complete rupture of the board is measured through a Digital Indicator. The bursting strength defines the material's quality as compared to the others. Bursting Strength Tester Genie 4.0 provides a hydraulic pressure on the sample. In the Presto Bursting Strength Tester, a hydraulic pressure is applied on the sample under test, using a neoprene diaphragm, on a circular area. So, a circular piece of the sample of the corrugated board is used for the test. Widely used in the paper and packaging industries, this Digital Bursting Strength Tester conforms to major global testing standards including ASTM D3786-01, ASTM D3786-80a, IS 1060 Part-1 1987, ASTM D774, ISO 2758, and ISO 2759. Compliance with these standards makes it a reliable choice for manufacturers who need precise quality control and international acceptance of their test results. Its dual test modes for paper and board, along with automatic calculation of bursting factor and pass/fail criteria, make it one of the most advanced solutions for packaging material testing.

Bursting Strength Tester Computerized –Burst genie 4.0 Computerized is a consistent tool to indicate the Strength and performance of material like paper boards, paper, uneven boards , boxes , solid fiber boards, Foils, sheets, etc. PRESTO Bursting Strength Tester is manufactured under various Test Standards ASTM D 3786-01, ASTM D 3786 – 80A, ISO 1060 PART-1 1987. Available in Various other models like digital model and Digital model with printer facility.

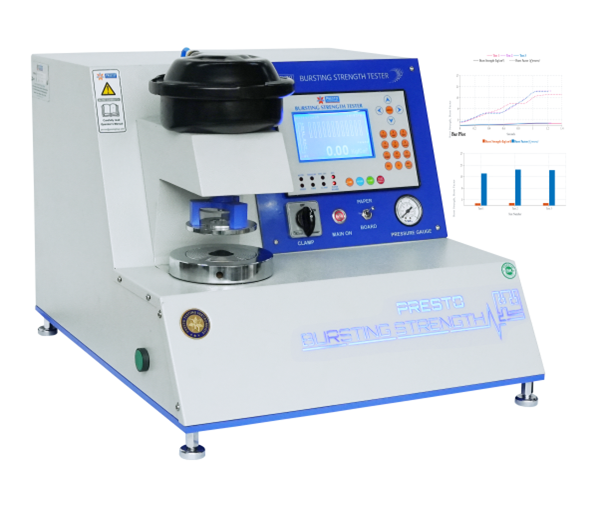

Bursting Strength Tester - Digital Pneumatic Burst Genie 4.0 is provided with digital display and pneumatic clamping system for determination of bursting strength of paper, paper-board, solid fiber board and corrugated board and boxes. The equipment is widely...

Pneumatic Burst Genie 4.0 Computerized is an automatic Bursting Strength Tester device used to measure the Bursting strength & bursting factor of packaging materials like paper, cardboard, and corrugated sheet to rupture under pressure. It operates by applying hydrostatic pressure uniformly to a test sample until it bursts, allowing accurate assessment of material durability and strength. The automatic feature enables precise and consistent measurements, reducing human error and increasing efficiency.

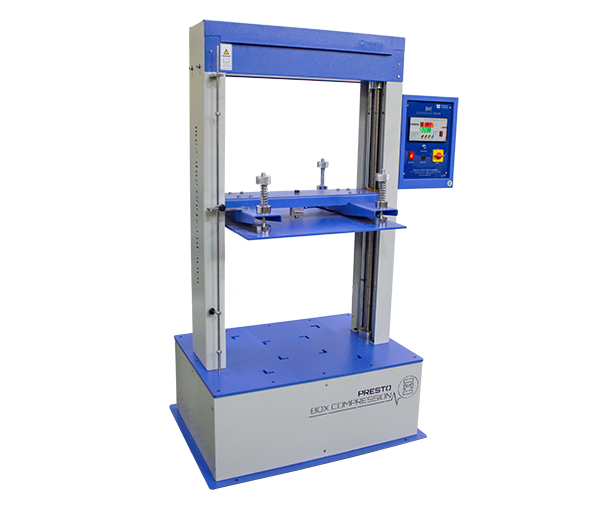

Box Compression Tester is a consistent tool to indicate the Compression strength of cardboard boxes so that it does not get deformed or crushed when stacked one above the other during storage or transit. Cardboard boxes are commonly stacked one on top of the other, during warehousing and storage. So, to ensure that they do not collapse during this, it is necessary to measure their box compression strength. It is based on the principle of measuring the maximum load that the material can withstand without breaking. This process is performed by applying a gradually increasing compression force to a sample until it fails using Box Compression Tester.

Using the equipment, a force-deformation curve can be obtained. This curve helps us evaluate the resistance of a package. It is a reliable equipment that provides accurate information regarding the compressive strength and durability of the package. It enables manufacturers to choose a more resistant packaging and to ensure the contents of the package don’t get damaged during stacking or transit.

Thus, corrugated boxes/cartons/paper packaging can be tested using Box Compression tester. It is widely used to determine compressive resistance, deformation and stacking capability of cartons and corrugated boxes.

Registered Design Patent No. 279106

In stock

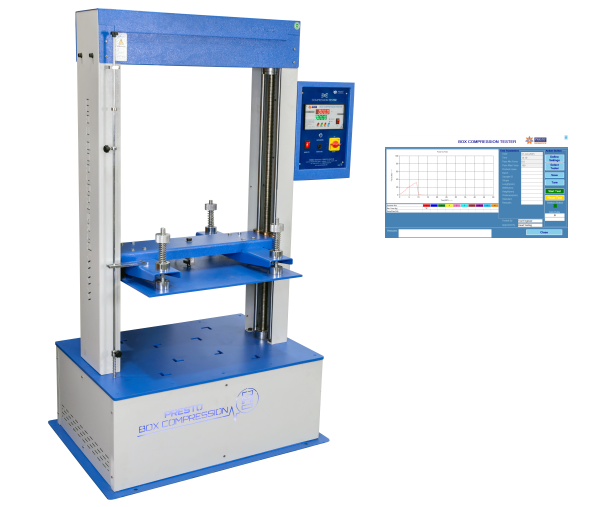

The PRESTO Box Compression Tester Computerised is a compact Instrument with user friendly controls & software. Cardboard boxes should possess sufficient compression strength so that they do not get deformed or crushed when stacked...

This equipment is designed to measure ability of the Mini cartons or printed Duplex cartons to resist external compression loads during transit and storage It is important to evaluate the Compression Strength of the Box in order to make sure that the box will be able to resist the anticipated compressive forces and to determine the load that the box will be able to withstand during transit and storage.

The cardboard strength and construction directly impact the amount of weight a box can carry. A box too weak might puncture or collapse. On the other hand, an excessive box means you pay extra for material and add to environmental wastage.

PRESTO Mini Box Compression Tester is manufactured under various Test Standards ASTM D642, ASTM D4169, TAPPI T804,

ISO 12048, and JIS Z0212

Registered Design No. 341519-002

Cobb sizing tester is used for fast determination of the quantity of water absorbed by a paper or board in a given time. The Water absorptiveness (Cobb value) of a substance is defined as the mass of water absorbed in a specific time by a 1 sq. meter...

RCT/FCT/Edge Crush Tester is a consistent tool to measure the crush strength of cardboard boxes and packaging containers. RCT/FCT/Edge Crush Tester reveals the crushing resistance in unit Kg/Unit length. It is a rigid support type compression...

.png)

The Presto Crush Tester – Digital Model is a high-precision instrument designed to measure the crushing strength of paper, corrugated boards, and related packaging materials. This versatile model performs multiple standard tests including Ring Crush Test (RCT), Edge Crush Test (ECT), Flat Crush Test (FCT), and Corrugated Crush Test (CCT) — making it an essential quality control tool for paper and packaging industries. Checks the compression sustaining strength specifying the plies and flutes quality.

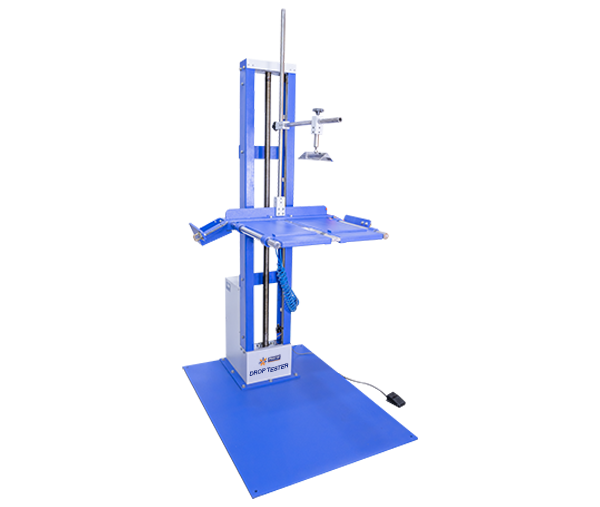

The Drop Tester (As per IS:7028 Pt IV) is a useful equipment for ascertaining the transport worthiness of corrugated & solid fiber boxes and shipping containers. It has provision with angular drop arrangement to help accurately ascertain the transport worthiness of the package from all angles.

In stock

Drop tester is the perfect machine to test the drop strength of the corrugated cartons. It is equipped with a wired remote-control mechanism to eliminate the human interference. The test specimen is observed visually after it is made to fall from a certain height. The instrument work with pneumatic application and used in almost every industry that deals with corrugated cartons.

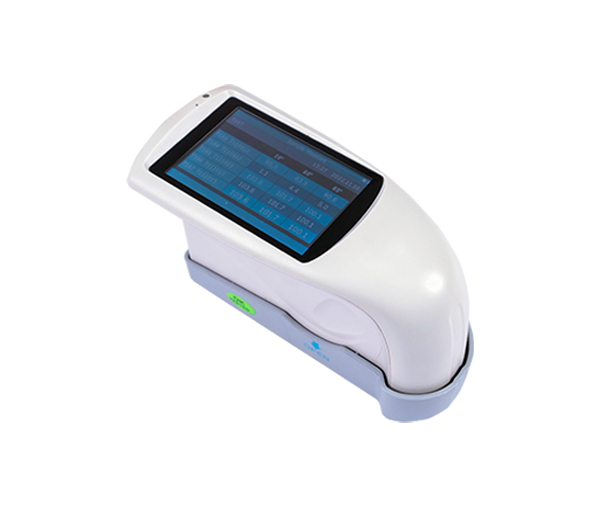

The gloss meter is available in different geometries to measure the specular reflection gloss of a surface or a material. The Gloss Meter Tri-angle is used to determine the gloss on a surface and measures the amount of reflected light.

PRESTO Round Cutter for Grammage GSM Round cutter is useful for precise circular cutting to check the grammage of samples. The sample cutter cuts out a circular specimen of 100? Which is exactly 1 / 100th of a square meter, rapidly and accurately.

Presto Moisture Meter PTM-2020 is the latest high sensitivity hand held moisture meter developed specially for the packaging industry. The portable moisture meter is used for measuring the moisture content of paper, corrugated sheets, cardboard stocks, kraft paper, paper tubes & paper bales,quickly and effectively.

(1).png)

Elevated temperatures can have a significant impact on the physical properties of many materials. Either it can deteriorate the quality of the product or will lead to product damage. This can have a major impact on the performance of products and structures made from these materials. Thus, it is important for product manufacturers to test the physical properties of the materials at elevated temperatures so as to determine their quality.

Presto manufactures Hot Air Oven Sterilizer, which is used to measure the effect of elevated temperatures on various types of materials such as textiles, rubbers, metal, yarn, paper and many more..

Presto Hot Air Ovens with Digital Temperature Controller are used to measure the effect of elevated temperatures on various types of materials like yarn, textile, plastics, rubber, paper, etc. Hence, it is mandatory to test the effect of ageing, heat resistance and heat deformation on the products that are manufactured in paper industry, rubber industry, and textile & yarn industry.

Presto’s Industrial Hot Air Oven is widely used to test the aging, heat deformation, and heat resistance of the materials that are manufactured in paper industry, textile industry, and various fields..

Hot Air Oven is a unique test cabinet designed to detect the change in the physical characteristics of the material and to ascertain the actual working life of testing device at elevated temperature. Works on Forced air circulation, thermal convection principle, suitable for Tests like heat deformation, compression set, heat resistance required in rubber and plastic industries.

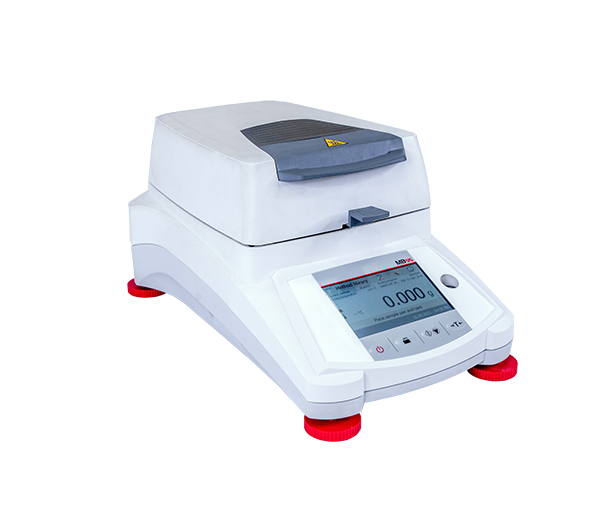

The Moisture Analyzer M95 is engineered to deliver faster, more accurate, and more efficient moisture measurements—helping quality teams test more samples in less time. With its advanced halogen heating system and intuitive user interface, the M95 offers the perfect balance of performance and ease of use for modern laboratories and production environments.

The MB95's halogen heating system distributes heat uniformly over the sample and speeds up the drying process, delivering fast and precise measurements.

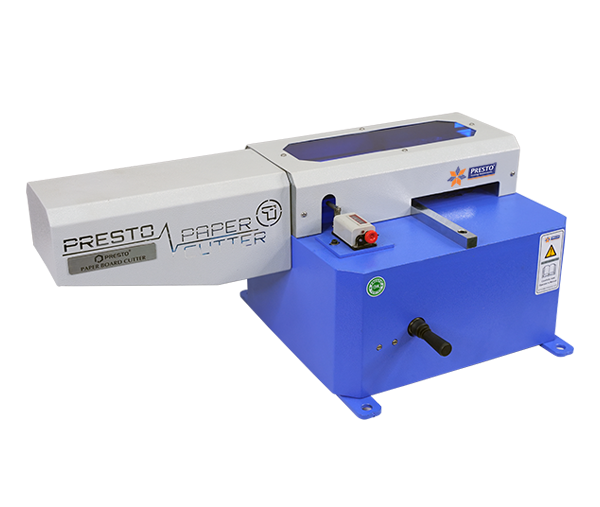

Paper and its related products are widely used in the paper and packaging industry to deliver accurate products to customers. Thus, to make it easy for the paper products manufacturers to test their material effectively, we at Presto have designed a paper board cutter. This is one of the amazing lab testing instruments that has been designed to effectively cut the samples for conducting edge crush tests on the materials.

Puncture Resistance Tester is a consistent tool useful to determine the resistance to puncture of paper and paperboard. Puncture Resistance Tester is used to measure the resistance of paper, paperboard and other similar materials when...

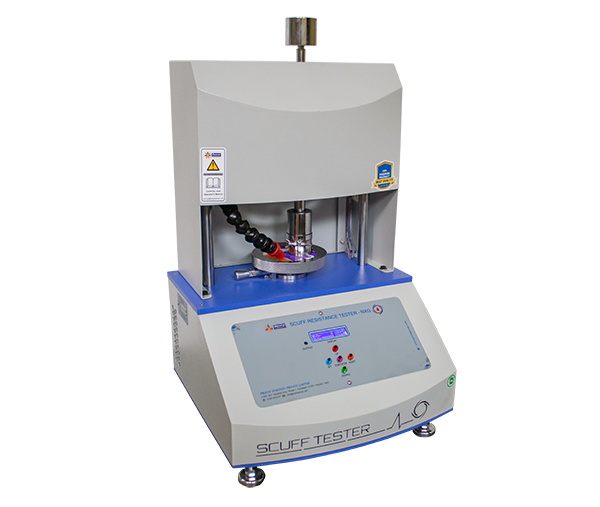

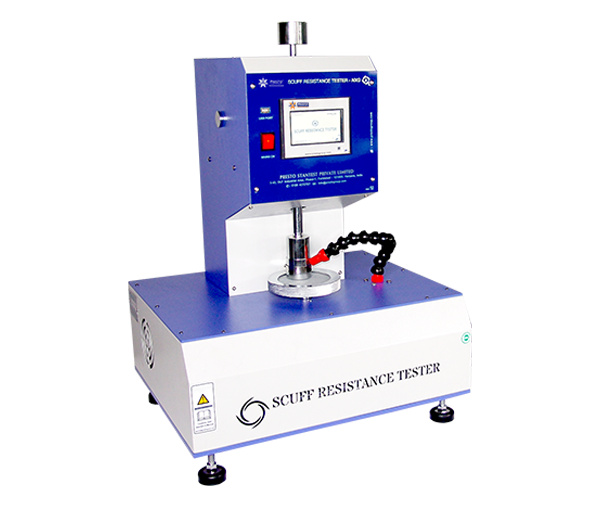

Scuff Resistance Tester is a unique test instrument to determine the color transfer from printed or coated material against rubbing. Scuff resistance testing can reveal how well a material will hold up against abrasion, rubbing, and scratching. This information is critical in industries such as packaging and printing where there is a vast use of labels and other printed materials.

Scuff testing of labels and other printed materials is used to determine their resistance to abrasion, scratching, or rubbing. This type of testing is essential for ensuring that the labels and printed materials can withstand handling and transportation without losing their legibility, durability, or aesthetic appeal.

The term scuffing is the rubbing of two materials against each other. Scuff Resistance Tester is used to evaluate the rub resistance (i.e. the damage which has taken place through rubbing) of labels and general printed matter.

In stock

.jpg)

A portable spectrophotometer is a consistent tool useful for performing several measurements on a variety of samples of colors such as white & black, dark & light and several other color boards. They are primarily used to reflect the measurements and best suited for the sophisticated color analysis such as the problem of metamerism.

Vibration simulation is an efficient and cost-effective way of determining damage caused by the repetitive movement in the vehicles. In just a few hours we can pinpoint potential damage areas in your package or product caused by vibration.

Our Vibration Table is customizable. You can get a Digital, Computerised, or touchscreen Vibration table according to your sample testing needs! Be it swivel, synchronous, or asynchronous, test your sample to its fullest to ensure durability, long life, and zero rejections.

Availability: In stock