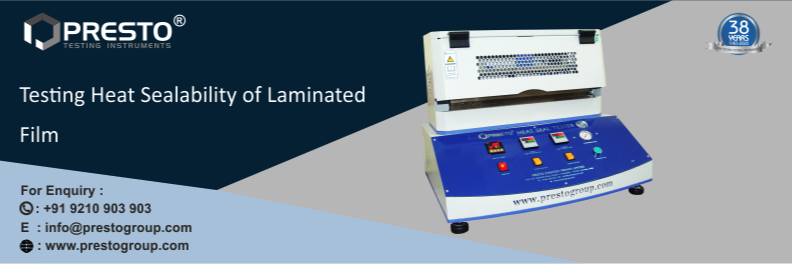

Testing Heat Sealability of Laminated Film

Laminated films have a wide range of applications in a variety of industries. Most commonly used for delivering protection and enhance the cover appearance. They also have packaging applications as well. During the lamination process, the Sealability of laminated films plays an important role and on the basis of this particular quality, they are price tagged in the market as well. Therefore testing the heat seal quality of these films is of utmost importance using Heat Sealing Testing Instruments.

To know more information about its features, price, and technical specifications, give us a call at +91 9210903903 or email us at info@prestogroup.com.

you may also like

- Evaluate the Surface Quality of Printed Materials with the Scuff Resistance Tester

- Perform Conditioning Procedures over variable materials with the Humidity Conditioning Chamber

- Safeguard Sensitive Products from Repetitive Movement by the Vibration Table

- Eliminate Excessive Moisture by Measuring It with the Moisture Meter

- Determine the Mechanical Properties of Plastic Materials with the UTM Machine

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Quick quote

.jpg)