Ensure Corrosion Proof Production with Salt Spray Chamber

How does Coating help to Protect Metals?

The coating of paint and plating on the facade of the metals is the most reliable source that protects the metals from corrosion. To test the resistance of the metal products to corrosion, corrosion testing is performed on the metals. The corrosion test can be performed efficiently with the help of “Salt Spray Chamber”. The manufacturers of salt spray chambers offer different models of the machine with customised specification and with sophisticated technology-based features. All the models of corrosion testing instruments are very effective that helps to determine the resistance of materials to corrosion in a salt, mist and fog environment. The coating is used to protect the quality of the metals from corrosion. Hence, the rust proof ability of the metals is crucial to detect in order to choose best and corrosion proof material.

How Can the Quality of Coating Be Measured?

The testing instrument “Salt Spray Chamber” is designed and assembled by the manufacturers of testing machine to test and to locate the resistant property of the coating to different environmental conditions. To test the same, the sample is subjected to a salty environment for a given period of time say 24 hours, 48 hours or depending on the test condition. The test sample is subjected to the salty environment and wet condition.

Assess the Actual Working Life of Metals with Corrosion Testing

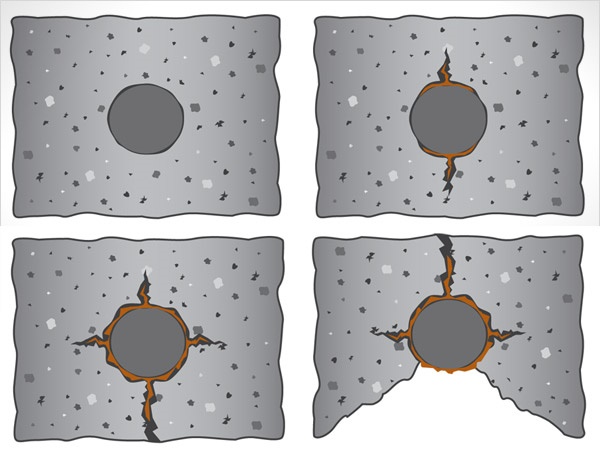

The corrosion testing is a significant process that helps the industries for the continuous production of industrial materials. The testing procedure contributes predicting the actual timing of the metal at which it can affect with the rust in salt or moist conditions and helps the manufacturers in planning the right quality of the coating to be used. The testing machine is mainly used in the automotive industries to test the corrosion resistant property of the spare parts or automotive parts. The corrosion of the material makes the metals weak and causes immediate damage.

At the time of corrosion testing with salt spray testing, corrosion cycles are set in the testing chamber with the salt water spray, dry or wet process, etc. to inspect the durability of the coated products. As per the requirement of corrosion resistance test, corrosion cycles are set to get the best correlation of the metal with the environment.

The testing device is designed mainly for the manufacturers of metallic products, painted and plated goods, etc. The test procedure offers different climatic conditions to detect the type of failure that can occur on the surface of the metal products. This is the best testing device which is used to determine the service life of the metals.

you may also like

- Safeguard Sensitive Products from Repetitive Movement by the Vibration Table

- Eliminate Excessive Moisture by Measuring It with the Moisture Meter

- Determine the Mechanical Properties of Plastic Materials with the UTM Machine

- How to Conduct Tensile Tests & Calibration on the Tensile Strength Tester?

- Evaluate Pressure Sustainability of Packets & Pouches with Vacuum Leak Tester

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Quick quote