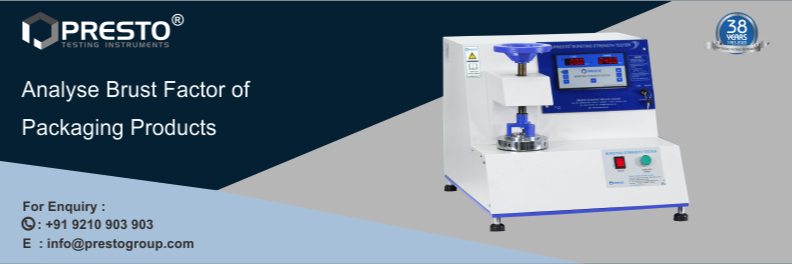

Analyse Burst Factor of Packaging Products

The paper and packaging industry form 43% of the total packaging industry. It has a market size of $369 billion (2017). The share of paper and board packaging against the total packaging consumption has been maintained above 40% in recent history. It has been flexible despite the appearance of other packaging materials. His has been assigned to properties like recyclability, lightweight, appeal, cost-effectiveness etc. The packaging industry plays an important role by adding value to several manufacturing sectors such as retail, pharma, etc.

The paper and packaging market contributes greater than 29% of the overall packaging market share. The demand for sustainable packaging either made from cloth, jute or plants is increasing day by day. Plastic is used for packaging that results in its innovative visual appeal to attract the customer. Due to the change in the lifestyle of people and consumption patterns, the demand for packaged products has increased manifold resulting in the growth of packaging industry.

Due to the above reason, the food safety and packaging norms are becoming stricter which results in promoting the use of good quality packaging. Bursting strength tester is the most common device to estimate the burst resistance of paper material, corrugated boxes and other paper board materials. The machine is used to test samples included manual operations like manual clamping and rotational wheel. With the advancement at every stage, the use of automation technology is required at every moment. Bursting strength tester-pneumatic model has auto burst feature to test precisely.

Bursting Strength testing machine is fitted with a pneumatic cylinder that gives pressure to push the clamp downwards and place a vertical load in the sample. Using pneumatic controls, there is no human interference. So, the test result is not hindered. The clamping section is designed to help the sample material and gives no slippage. The base test areas are fluted with circular design so that a definite amount of friction between the sample and the base at the time of test is maintained and it does not move from its place.

The display screen of Presto’s Burst Strength Tester is chip based that shows accurate result including pressure applied, at the point when the sample gets bursted. The burst point is the peak load of the sample that fails. This load value is saved in the memory for future usage. The feather touch control button is used for the user’s comfort. A standardised and accurate gauge to monitor the pressure applied.

you may also like

- Evaluate the Surface Quality of Printed Materials with the Scuff Resistance Tester

- Perform Conditioning Procedures over variable materials with the Humidity Conditioning Chamber

- Safeguard Sensitive Products from Repetitive Movement by the Vibration Table

- Eliminate Excessive Moisture by Measuring It with the Moisture Meter

- Determine the Mechanical Properties of Plastic Materials with the UTM Machine

Recent News

- Paper & Packaging Testing Instruments

- Paint, Plating & Coating Testing Instruments

- Plastic & Polymer Testing Instruments

- Environmental Testing Chambers

- PET & Preform Testing Instruments

- Color Measuring Testing Instruments

- View Entire Range Instruments

Catalogue 2023

Get information about new product launches, research, innovation and endeavors at Presto.

download Free Copy

Quick quote